peanut kernel screw oil press machine in botswana

- Type: peanut oil press

- Usage/Application: peanut, groundnut

- Production capacity: 100-500 kg/h

- Voltage: 220 V/380 V

- Main components: motor, pump, PLC, oil making machine

- Weight: 900 kg

- Dimension (length x width x height): 2000x1500x1720 mm

- Country: botswana

1. A wide range of application. It can press more than 20 kinds of oil plant seeds, such as peanut, peanut, Peanut, rapeseed, sunflower, Peanut, Peanut, coconut and flax seed, etc. 2. High oil yield and purer oil. The equipped vacuum filter is used to remove residue to ensure the pure oil quality and meet the standards of health quarantine. 3. 1.

What are the common extraction methods of extracting peanut

- Type: peanut oil processing machine

- Production capacity: 1-100T/D

- Voltage:380V/440v

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

- Power (W) : 20-50KW

As the core equipment of the peanut oil pressing production line, peanut oil press machine plays a huge role in the whole peanut oil pressing process. According to the different processing capacity of customers, there are usually 4 kinds of peanut oil press machine for people to choose, they are: large screw peanut oil press machine, small

The researchers found that optimal conditions for air roasting were 180 °C for 10 min, followed by cooling at room temperature. Oil extraction using screw pressing at a temperature below 50 °C resulted in a yield of 41.18–46.28%, followed by centrifugation of the oil at 12,000 rpm for 10 min to remove impurities.

Peanut Oil Press-- Integrated Screw Oil Press for Both Cold

- Usage: peanut oil

- Production capacity: 10TPD

- Voltage: 220V380V

- Main components: motor, pressure vessel, PLC

- Weight: 300 KG

- Dimension (L*W*H): 1.2*0.78*1.1m

Automatic Peanut Oil Press Machine. Automatic peanut oil press machine is a kind of superior oil pressing machine nowadays in the market. It is used for processing cooking oil from various oil bearing materials such as peanuts, soybeans, sunflower seeds, rapeseeds, oil palm, sesame seeds and so on.

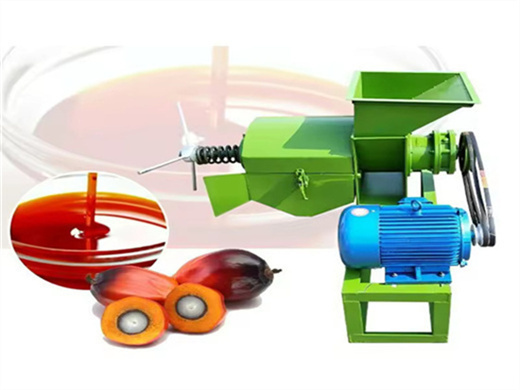

After bunch reception, bunch sterilizing, threshing and digesting, the palm fruits are pressed into a screw palm oil press. Mixture of oil and cake will be extracted by use of palm oil press machine. Besides, nuts and fibre or press cake will also be discharged as palm oil pressing residues. Screw pressing is the main method of palm oil extraction.

peanut oil processing and basic principle and method of

- Type: cooking oil extraction machine

- Production capacity: 1-2000TPD

- Power ( W): 7.5kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 1200kg

Highly efficient centrifugal oil filtering equipment suitable for a great deal of crude oils, including rapeseed oil, cotton seed oil, soybean oil, peanut oil, flax seed oil, sunflower seed oil, corn germ oil, palm kernel oil, etc. 5. The type of centrifugal oil filter is perfect to match with various screw oil press machines.

The conditioned peanut kernels are transported by a conveyor to the twin-screw press for cold pressing; the cold-pressed crude oil and cold-pressed peanut meal with low denaturation will be obtained. After the cold-pressed crude oil is filtered with frame filter, product oil is obtained, which will be packaged by a filling machine to form cold

Peanut Oil Extraction Methods

- Raw Material: peanut

- Voltage: 220V/380V/440V

- Dimension (L*W*H ): 48m*12M*15M(30TPD)

- Power (W): 22kW cooking oil making machine

- Weight: 30 tons

- Certification: ISO CE

Peanuts are the main oil crops and contain high nutrition, but the quality, color, taste and even the oil yield of the peanut oil extracted by different peanut oil extraction machine are different. These are inseparable from the causes of the press, but they are also related to the different processing methods.

Step 3: Preheat the Oil Press Machine Before using the oil press machine, it is important to preheat it. This can be done by turning on the machine and allowing it to heat up for a few minutes. Preheating the machine helps to optimize the extraction process and improve the yield of oil. Step 4: Adjust the Settings