Expert on Edible Oil Production Line and Vegetable Oil

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Production capacity: 5TPD-100TPD

- Voltage: 220V/50HZ three-phase

- Warranty: 1 year, 1 year

- Weight: 27.1 KG

- Dimension (L*W*H)): 1055*805*345mm

- Country: afghanistan

30T/D Edible Oil Production Plant; 10-20T/D Edible Oil Production Line; 1-50T/D Edible Oil Production Line; Oil Refinery Plant. Large Continuous Edible Oil Refinery Plant 20-5000TPD; Batch-type Edible Oil Refining Equipment 1TPD to 20TPD; 10T/D Edible Oil Refinery Plant; 1-5T/D Edible Oil Refinery Plant; Cotton Seeds Oil Refinery Plants; Seed

Small Oil Pressing Line. Small Oil Mill Plant. Edible Oil

- Type: peanut oil refinery machine

- Voltage: 380v/50Hz

- Power (W): up to specification

- Certification:ISO9001

- Weight: up to specification

- Dimension (L*W*H):1360*950*1170mm

The Batch-type edible oil refining equipment is designed to handle various types of crude oils, including palm oil, soybean oil, sunflower oil, peanut oil, and more. It performs several refining processes in a batch mode, allowing for flexibility and control over the refining process.

The Edible Oil Refining Plant Cost in small scale level ranges $21,000~$115,000. For more specific cost, please directly contact us. Our professional engineers and sales will takes all your requirements into consideration and offer you custom edible oil refining plant and corresponding cost. Edible Oil Refining Plant Types

Oils Fats Refining Equipment and Turnkey Plants - Myande Group

- Usage: peanut oil

- Production capacity: 100%

- Voltage: 380 V

- Weight: changes according to capacity

- Dimension (L*W*H): various according to capacity

- Power ( W): according to capacity

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

You need to set up an oil refinery line for your oil mill plant to avoid oxidization of crude edible oil and get rid of impurities or hazardous substances. Toggle navigation info@bestoilmillplant.com 0086 372 5965148

Physical Continuous Type Edible Oil Refinery Plant

- Type: cooking oil refining machine

- Production capacity: 10TPH-60T/H

- Power ( W): depends on capacity

- Voltage: 220V/380V

- Dimension (L*W*H) : depends on capacity

- Weight: depends on capacity

Unlike batch oil refining process in which oil is processed in measured batch, in Continuous Vegetable Oil Refinery, crude oil is processed continuously with a constant stream of flow. During the process, necessary chemicals and other utility items added continuously in the measured quantity.

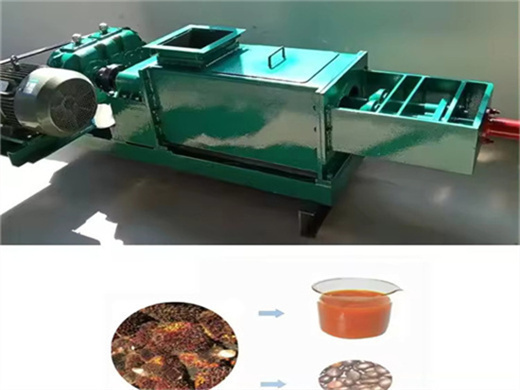

Full set 3T-5000TPD vegetable seed oil production line Oilseeds scope also: soybean, rice bran, peanut, sesame, sunflower seed, rapeseed, cottonseed, corn germ, copra, castor bean and so on. Vegetable Seed Oil production Line including: Oil Pretreatment and Prepressing equipment, Oil Extraction equipment, and Oil Refinding equipment

Professional Oil Refining Plant for Edible / Vegetable Oil

- Raw Material: peanut

- Voltage: Adjustable

- Residual solvent in finished food: ≤ 300 ppm (qualified detonated experiment)

- Certification: ISO CE

- Oil grade: Grade 1

- Moisture of finished food: ≤ 10-13% (adjustable)

Edible/Vegetable Oil Refining. Edible/vegetable oil refining is a step by step process. Refining oil removes phospholipids, pigments, off-flavors, free fatty acids and other impurities. The entire oil refining plant process comprises degumming/neutralization, bleaching, deoderization, and winterization. Chemical refining is performed in order

peanut production line has several advantages: high oil yield, high degree of automation, energy saving and environmental protection, and customized services. Hongde Machinery provides comprehensive customized services, tailoring complete pre-pressing and extraction production lines according to the specific needs of customers (such as raw material characteristics, production scale, product standards, etc.).