Separators for Oil Recovery - GEA

- Type: palm oil machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 5t/day-5t/hour

- Voltage: Customization

- Warranty: More than 5 years

- Weight: 20000 KG

- Dimension (L*W*H): Customization

- Country: zambia

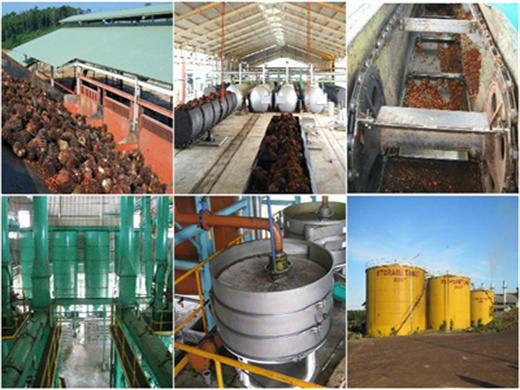

GEA also offers special nozzle separators to the palm oil industry in order to recover oil from sterilizer condensate. 3-Phase Separating Decanters for Oil Recovery For the recovery of olive, palm and other vegetable crude oil the decanter is always the heart of the installation. 3-Phase decanters separate both, the olive pulp or the palm oil

VO vegetable oil separators | Alfa Laval

- Type: palm oil processing machine

- Production capacity: 95%

- Voltage: 220v

- Warranty: 12 months

- Weight: 160 KG

- Dimension (L*W*H): 900x450x630mm

VO separators range was designed to increase oil yield and produce refined oil of better quality. Enhanced with a special feature – manual Centrizoom paring disc outlet – these centrifuges are ideal for degumming, neutralization and washing, they ensure optimal mixing and separation, allow to increase efficiency of the plant and to reduce production costs.

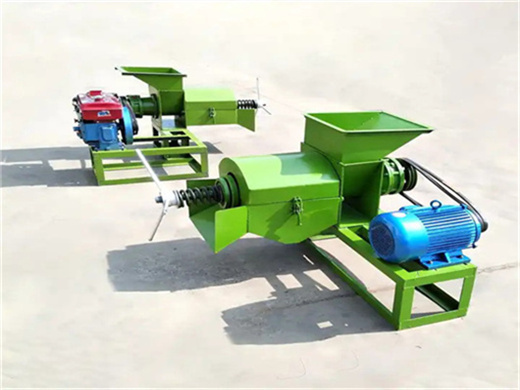

As for different palm oil processing capacity, there two kinds of screw palm oil press machine for people to choose, one is screw palm oil press machine, the other is double screw palm oil press machine. Screw palm oil press machine. 6. Oil Clarification Station: for the filtration stage, a vibrating screen, an crude oil clarification tank

Palm Oil Clarification Processing Machinery Equipment

- Usage: palm oil

- Production capacity: 20tpd-100%

- Voltage: 220VAC 50Hz/380V 50Hz

- Main components: Engine, Motor

- Weight: KG

- Dimension (L*W*H): as per order

Palm oil fractionation technology divides palm oil into liquid and solid oil by different welding points and different solution of various triglycerides composing oil. We assure the most precise design, high quality Palm Oil Clarification Station Machine, mature project installation, and perfect after sale services.

Medium-capacity disc stack separator for fats and oil refining Introduction The use of Alfa Laval disc stack separators in the vegetable oil and refining industries goes back to the end of 19th century. The application ranges from fats and oil refining to palm oil washing. Application The VO separator range is designed for and can be adapted

️ Alfa Laval SSRPX614 - used Vegetable oil separator for

- Type: cooking oil extraction machine

- Production capacity: 50T~100T/D

- Power ( W): 11KW

- Voltage: 220V/380V

- Dimension (L*W*H): According to capacity

- Weight: 1000kg

Separation takes place in the separator bowl which is driven by the electric motor via a flat belt. The separator can be used as a concentrator with a large heavy phase (e.g. water) and a small phase (e.g. oil) as well as the sludge phase. The separator can also be used as a cleaning separator ( clarifier ) with only the sludge separation.

Among these steps, degumming and neutralization are particularly crucial as they involve the separation of gums and soaps from the oil. This is where the vegetable oil separator plays an indispensable role. By utilizing centrifugal force, these separators efficiently remove impurities, ensuring the production of pure and stable oils.

Vegetable oil - Andritz

- Raw Material: palm

- Production capacity: 80%

- Dimension (L*W*H): 48m*12M*15M

- Voltage: 380V/440V

- Weight: 100 kg

- Main components: motor, others, gears, cooking oil production line

Whether you are producing palm oil, rapeseed oil, olive oil, or other edible oils, you want to be more competitive. Margins are tight. Taste is key. Sustainability is important. The challenges are as diverse as the industry itself. Which is why you need a separation partner that understands your process and can offer a wide range of solutions.

3-Phase decanters separate both, the olive pulp or the palm oil sludge into oil, water and solids. This 3-Phase separation requires a comparably high amount of dilution water. In olive oil production GEA also offers 3-Phase decanters for treating the waste water from the olive oil recovery process.