[Hot Item] Water Cooling Peanut Oil Milling Plant Equipment

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Production capacity: 1t/day-1t/hour-100%

- Voltage: 220 V, 380 V, 440 V

- Warranty: 1 year, 12 months

- Weight: 750kg

- Dimension (L*W* H): 1600mm*1200mm*1000mm

- Country: tanzania

10 tons per day groundnut oil making machine is a complete groundnut oil pressing line, which can process 10 tons groundnuts within 12 hours. Different from 5 tons per day groundnut oil processing machine, the integrated oil press machine with vacuum filter will be replaced by the single screw oil press machine and plate filter, for getting higher quality groundnut oil.

Hongde Provides Turnkey Oil Mill Plant, Oil Pressing Machine

- Type: peanut oil processing machine

- Production capacity: 1-2000TPH

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

- Power (W) : 18.5 KW

We are able to supply the professional oil refining plant and related oil refining equipment. With a high degree of automation, the oil refining machinery can refine 20 kinds of oil, such as soybean, rape seeds, peanut, etc. in a small production line or in a large oil plant. SEE MORE

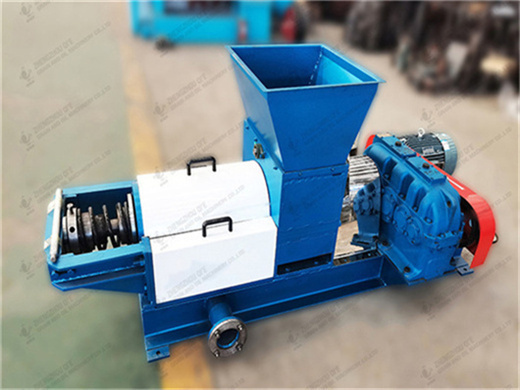

The most important equipment in the entire milling / pressing process is oil expellers which are used for high oil content seeds and also used for smaller capacity oil production plant. In former times, oil extraction was done exclusively with presses. In most oil milling plant, oil extraction is done with expellers as pre extraction before

Peanut Oil Processing Plant - Oil Mill Machinery

- Usage: peanut oil

- Production capacity: 7 to 8 TONS/DAY

- Voltage: 30 HP

- Main components warranty: 5 years

- Weight: 5500 KG

- Dimension (L*W*H): 2641MM*1016MM*2489MM

According to their dispersion state, the impurities in peanut oil can be divided into four categories: (1) suspended impurities (2) colloidal impurities (3) oil-soluble impurities (4) water. Peanut oil refining is to remove harmful impurities and unnecessary substances from crude oil by physical methods and chemical processes according to

Adding filter aids: The purpose of adding filter aid is to improve the final filtration effect, accelerate the formation of filter cake, reduce the content of phospholipids and peptized impurities in refined oil; filter aids are activated carbon and solid peanut cake powder; the added amount is about 0.1% of the weight of the oil. Secondary

Build Oil Mill Plant with BEST Oil Expeller & Refinery Line

- Type: cooking oil extraction machine

- Voltage: 380V

- Weight: 200kg

- Power (W): 39kw

- Dimension (L*W*H): 1500*900*1900mm

- Material: 304 Stainless Steel

150TPD Sunflower Oil Processing Plant Business in Russia. There are great potentials to start vegetable oil production business by setting up sunflower oil processing plants in Russia. This 150TPD sunflower oil processing plant was successfully installed in 2011. It is a complete vegetable oil mill plant tha...

Peanuts are oilseed with a high oil content. Peanut solvent extraction and mechanical pressing are the widely used commercial or industrial peanut oil extraction methods for peanut oil production due to their high efficiency of oil production, scientific oil extraction process, and relatively cost-effective oil extraction equipment.

Oil processing equipments of oil mill plant

- Raw Material: peanut

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 1200*600* 2000 mm

- Voltage: 220V/380V

- Weight: 100 KG

- Main components: motor, pump, PLC

These oil mill can process a number of oilseeds like peanut, soya, cotton seeds sunflower seeds, corn germ, rape seeds, canola, castor, sesame, neem seed, sheanut, palm kernel and the like. The most important equipment in the entire milling / pressing process is oil expellers which are used for high oil content seeds and also used for smaller

The Batch-type edible oil refining equipment is designed to handle various types of crude oils, including palm oil, soybean oil, sunflower oil, peanut oil, and more. It performs several refining processes in a batch mode, allowing for flexibility and control over the refining process.