MDY-400 Type Hydraulic Cotton Baling Press Machine

- Type: cottonseed oil press machine

- Usage/Application: cottonseed

- Production capacity: 1t/day-1t/hour-100%

- Voltage: 180~240V, 50-60 HZ

- Main components: Motor

- Weight: 65 KG

- Dimension (L*W* H): 72*41*70CM

- Country: lagos

Choosing a good baling machine will make the whole production line perfect. With advanced design, our MDY-400 hydraulic cotton baling machine can automatically complete multiple processes, such as cotton collecting, feeding and pushing, box rotating and releasing, baling, weighing, printing, conveying, etc. thus realizing continuous production.

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cottonseed oil processing machine

- Production capacity: 100% cooking pellet press

- Voltage: 220V/380V/440V

- Weight: Depends on its capacity

- Dimension (L*W) *H): Depends on its capacity

- Power (W): Depends on its capacity

The residue & solid powder is separated through automatic oil-dreg separator. After separating, we can get two products, one is crude oil with impurity of 1% which will be refined or filtered further by Filtered Press; the other is residue with oil which is conveyed back into Screw Press to repress to get rest oil. Cottonseed Oil & Cottonseed Meal

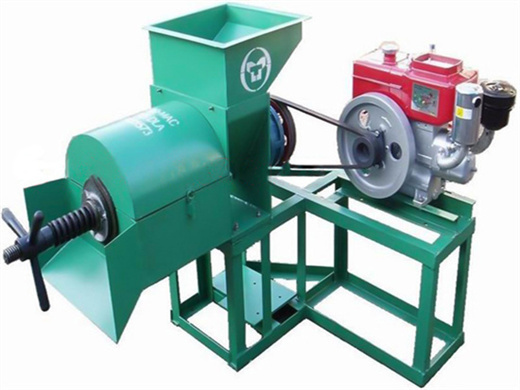

Use the electric motor or diesel as engine; high oil output,qualified oil,simple design and continuous operation;pressing various oil seeds,such as peanut, soybean,flax seed,cotton seed and so on;labor and energy saving because of the improved design;

Cottonseed Oil Manufacturing Process and Machinery

- Usage: cottonseed oil

- Certification: ISO, BV, CE, CE, ISO9001, BV, etc...

- keyword: cooking oil productions

- Power consumption: ≤ 15KWh/T

- Steam consumption: ≤ 280KG/T (0.8MPa)

- Residual oil in flour: ≤ 1%

Looking for a quote on a screw oil press capable of doing 1-5 tons per day. Would prefer a catalog with prices of all your products if it is available. Looking at installing a cottonseed press facility. Thanks; Hello, dear. As you requested, we suggest our YZS-95 oil press machine for your reference. The detailed technical parameters and price

Auxiliary equipment of cotton processing machines is also provided. MDY-400 Type Hydraulic Cotton Baling Press Machine Our hydraulic baling press machine can complete the continuous cotton baling process automatically.

Press Machine - Types , Parts , Diagram , Specifications

- Type: cooking oil extraction machine

- Production capacity: 20-1000T/D

- Voltage: 220V, 380V

- Weight: According processing capacity

- Dimension (L*W*H): Our engineer will design it according to your capacity

- Power (W): According to the capacity of the cooking oil pre-pressing machine

Press Machine. A press machine is a sheet metal working tool with a stationary bed and a powered ram can be driven towards the bed or away from the bed to apply force or required pressure for various metal forming operations. A line diagram of a typical pres is explained in the Figure. hydraulic system.

The YZS series automatic oil press is an advanced cotton seed oil extruder which is developed on the previous single oil press machine according the market demands. It has strengthen the function of frying and automatic controlled temperature, which has changed the traditional way for increasing dry cake's temperature, therefore it reduced the working time, and also reduced the waste of power

Types of Oil Extraction Machines

- Raw Material: cottonseed oil

- Form: Oil

- Extraction type: Cold pressed

- Part: Seed

- Packaging: Bottle, Drum, 20kg, 250KG, 190kg, IBC Drums, Flexibag

- Grade: Edible Grade, EP, BP

The capacity of a press oil machine is usually expressed in terms of the weight of raw material that it can process per hour. A simple commercial oil press machine may have a capacity of anywhere between 3 kg and 100 kg (6.6 lb to 220 lb) of input material per hour. More complex commercial oil press machines may have much higher per-hour

The manual press machine can be used for punching, blanking, and bending and is ideal for small runs and easy production. Hydraulic Press Machine. The hydraulic press machine propels the ram through many hydraulic system components, with the oil cylinder typically mounted on the top beam.