Sunflower Oil Processing - Oil Mill Plant

- Type: sunflower oil processing plant

- Usage/Application: sunflower

- Voltage: 380 V

- Power (W): 45 KW

- Certification: Ce

- Dimension (L*W* H): 1080*840*1750

- Weight: 10 tons

- Country: mozambique

The oilseeds are prepared and pressed to get the maximum amount of sunflower oil with the minimum amount of effort. KMEC is a leading company in sunflower oil processing. We are able to design a complete sunflower oil plant and offer quality sunflower oil processing machinery. We are your trusted sunflower oil processing plant manufacturer

Invest in Affordable Small Sunflower Oil Production Line

- Type: sunflower oil processing machine

- Production capacity: 300-400

- Voltage: 380 V

- Weight: 130kg

- Dimension (L*W*H): 1600*1100 *1150mm

- Power (W): 0.75 kw

For industrial scale edible oil mill plant with daily capacity more than 20 tons, sunflower seed dehulling machine is necessary. The main process of fully scale sunflower oil processing plant is shelling, pre-pressing, solvent extraction, oil refining and oil filling. (Extract oil after dehulling can reduce the wax content of final oil.)

Sunflower oil is extracted from sunflower seeds. It's a highly nutritious edible oil, rich in nutrients such as linoleic acid and vitamin E. It benefits the immune system, can prevent cancer, and due to its antioxidant and anti-inflammatory properties, it can also help prevent asthma. As a result, sunflower seed oil finds extensive commercial and household applications, especially in the food industry.

Sunflower Oil Production Plant Process Flowchart - GOYUM GROUP

- Usage: sunflower oil

- Production capacity: 5TPD-100TPD

- Voltage: 220V/380V<br /Power: 450w

- Raw material: Oilseeds

- Weight: 11kg

- Dimension (L*W*H): 450*180*230

Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system, the goodness of sunflower oil can help take

The sunflower seed contains 35 – 40 % oil content and double pressing is required to extract maximum oil, 9 – 11 % residual oil is left in the sunflower meal which is an excellent source of Animal Feed.

sunflower oil refining properties | Supply of turnkey project

- Type: cooking oil extraction machine

- Production capacity: 20kg/lot

- Dimension (L*W*H)): 1100*1240*1730 mm

- Voltage: 220v/380v/customizable

- Weight: 1750 kg, 1750 kg

- Main components: motor, hydraulic system

sunflower crude oil refining machine in mozambique. Press Series: Firsty Class Oil; Customized: Customized; Certification: CE, ISO, ISO9001 and Others

Complete Sunflower Oil Manufacturing Process Flow Chart. Our Machinery has been a reliable manufacturer of sunflower oil processing equipment for many years. The configuration of sunflower oil processing plant can be customized according to the customer's production needs offer from about $7500.

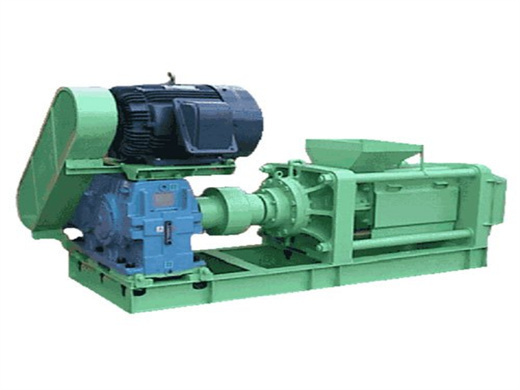

Sunflower Oil Mill Plant

- Raw Material: sunflower

- Production capacity: 20~2000T/D

- Power (W) : up to specification

- Voltage: 380v/50Hz

- Dimension (L*W) *H): 1360*950*1170mm

- Weight: up to specification

In the whole sunflower oil production line, sunflower seeds should be shelled, cleaned, cooked, and pressed. a sunflower oil solvent extraction plant is used to achieve a high oil yield. Through the sunflower oil solvent extraction process, the oil residue will be less than 1%, and the meal will be more suitable for animal feed.

This turnkey solution for 50tpd sunflower oil production line integrates cutting-edge sunflower oil production machinery, automation and sustainable practices to deliver a seamless workflow from raw sunflower seeds to high-quality refined sunflower oil, catering to small and medium-sized enterprises aiming to thrive in the competitive edible oil market.