Soybean Oil Production line – Liangli Machinery Equipment Company

- Type: soybean oil plant

- Usage/Application: soybean

- Production capacity: 1TPD-1000TPD

- Voltage: 380V

- Weight: changed with capacity

- Dimension (L*W*H): various with capacity

- Power (W): according to capacity

- Country: cameroon

According to the quality of oil and the different requirements of customers, we can reasonably select and combine the refining process, select the best process route, and exquisite equipment production and automatic control system to provide customers with perfect technical services and meet domestic requirements.

Soybean Oil Production Line-Soybean Oil Solvent Extracting Plant

- Type: soybean oil processing machine

- Weight: 2,400 kg

- Main components: Others

- Advantage: Simple operation

- Product Function: Edible oil making

- Oil type: Cooking oil

The soybean oil production line includes the soybean pretreatment process, soybean pre-pressing process, soybean oil extracting process, and soybean crude oil refining process. Our advanced soybean oil equipment, such as solvent extractors and automatic control systems, ensures high yields and consistent quality of both crude and refined oil.

The soybean oil production line is the process of treating soya bean with the press method or leaching method to obtain more crude oil and then refined to obtain edible refined oil. Pressed soybean oil has natural colors, aromas and flavors, and retains raw material’s various nutritious ingredients when comparing with the leached oil.

Soybean Oil Mill / Oil Extraction Plant Manufacturers

- Usage: soybean oil

- Voltage: 220 V/380 V/440 V

- Power (W): 7.5 kW

- Certification: CE ISO

- Weight: 1200kg

- Dimension (L*W) *H): 2000x1400x1850mm

Soybean Oil Extraction Process. Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.

The Soybean Oil Production Line offered by GOYUM is robust, versatile, reliable, and efficient. This Soybean Oil Production Line is based on practically proven technology which is not only energy efficient & environment friendly, but also economical. Goyum Group's successful installation of a 110 TPD Soybean Oil Production Line in India.

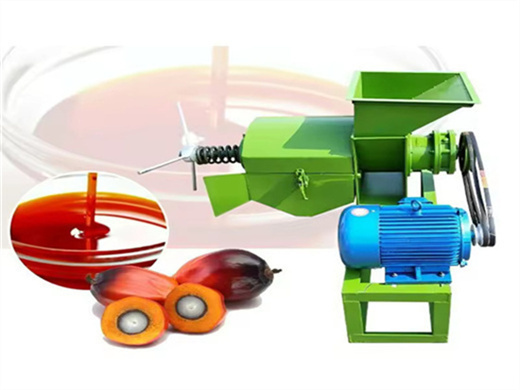

soybean oil press machine ghana in cameroon

- Type: cooking oil extraction machine

- Production capacity: 2-4t/d

- Dimension (L*W*H): 1320X540X1020mm

- Voltage: 5.5kw/380v

- Weight: 350 KG

- Main components: motor, others, gears, bearings, motor, gearbox

Soybean Oil Production Line Installed in Ghana. This efficient soybean oil production line was built in Ghana to produce high quality edible soybean oil. This soybean oil pressing section consists of cleaning equipment, flaker, steam cooker, screw conveyor and three set of Soybean Oil Oil Press Machine. And the oil refinery section adopts Batch

Ours hot sale oil machine include : palm kernel oil production line equipment, Soybean oil production line,palm oil production line equipment,Vegetable Oil Solvent Extractor,Cold Press Oil Machine,Sunflower oil extractor,Edible oil refinery machine,Mini oil mill plant,Multifunction oil press machine,Automatic oil press machine etc. QI ' E Group

Soybean Oil Production Line-Soybean Solvent Extracting Plant

- Raw Material: soybean

- Certification: ISO CE

- Power: 14KW

- Product type: cooking oil refining machinery

- Residual oil in flour: <1%

- Material: carbon steel, stainless steel

As the last process for the soybean oil processing plant, deodorization aims at removing the substance that causes odors in soybean oil. Soybean Oil Production Line Advantages. 1. Perfect cleaning process: 99% impurities contained in the soybean can be removed in this process, thus reducing the mechanical wear and ensuring the soybean quality. 2.

The pre-treated soybean embryo flakes are sent to the soybean oil extraction plant, and the oil is extracted from the soybeans by using 6# solvent (n-hexane), and then the solvent is separated from the crude oil and recycled; the crude oil is sent to the soybean oil refining plant for refining. 3. Soybean Oil Production Line - Refining Section: