EFB Pellet Machine - RICHI Pelletizer

- Type: cottonseed oil making machine

- Usage/Application: cottonseed

- Production capacity: 1-100TPH

- Voltage: 220V/380V

- Weight: 15TONS

- Dimension (L*W*H): 2000x1400x1850mm

- Power (W) : 18.5 KW

- Country: south africa

Efb pellet mill is compact, easy to operate, and has excellent performance, which makes it the ideal equipment for making efb pellets today. In addition, the efb pellet machine can process not only the efb pellets but also all kind of biomass pellets, such as grass pellets, leaf pellets, wood pellets, straw pellets, rice husk pellets, and etc.

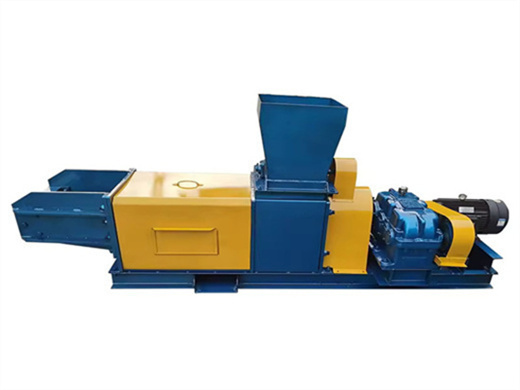

Empty Fruit Bunch Shredder, EFB Fiber Crushing Machine

- Type: cottonseed oil processing machine

- Production capacity: 50-60 TPD

- Voltage: 100 HP

- Main components warranty: 5 years

- Weight: 12000 KG

- Dimension (L*W*H): 3505*1820*1981MM

It is one key machine of EFB pellet plant and can directly crush the fresh EFB into 10~30mm length fiber. The output fiber could be easily dried and fine crushed in the following EFB pellet processing, which guarantees the high quality of the final EFB pellets products. EFB Shredder Features 1. Easy Installation

In the following, an EFB pellet plant line established for a Serbia EFB pellet manufacture is presented for your reference. Generally information about the EFB pellet plant are shown as follow: Capacity : 4-5 ton / per hour; Raw Materials: EFB palm fiber powder; Main Equipment: Conveyor, dryer, cooler and EFB pellet machine

EFB Pellet Machine | Complete EFB Production Line

- Usage: cottonseed oil

- Voltage: 380V

- Appearance: Horizontal

- Customized: Customized

- Press series: Fourth

- Press materials: Canola oil extraction machine

Therefore, different types of empty fruit bunch pellet mills have different uses in biomass fuel plants, palm oil plants, organic fertilizer plants, animal feed plants, etc. EFB pellet machines can be used by individuals or factories, and efb pellet factories can sell biomass fiber pellets to any company or individual who needs biomass energy.

Cottonseed oil is a cooking oil extracted from the seeds of cotton plant of various species, mainly Gossypium hirsutum and Gossypium herbaceum. Cotton grown for oil extraction is one of the big four genetically modified crops grown around the world, next to soy, corn, and rapeseed (canola), mostly Monsanto products. Once processed, cottonseed oil has a mild taste and appears generally clear with a light golden color, the amount of color depending on the amount of refining. Cottonseed oil has a relatively high smoke point as a frying medium. Like other long-chain fatty acid oils, cottonseed oil has a smoke point of about 450 ℉ (232 ℃).

1-20T/H Palm Waste EFB Pellet Machine For EFB PKS OPT Fuel

- Type: cooking oil extraction machine

- Product type: Wood oil

- Packaging: Bulk

- Processing type: Refined

- Purity (%): 100

- Refined type: Hydrogenated oil

When you feed EFB into the EFB pellet mill, it is pressed by the friction between pellet mill roller and die. The lignin in the EFB will become soften and glutinous under high temperature. When they come out from the holes on pellet machine dies, the EFB materials have been pressed together and become high-density pellets.

Specialized EFB Pellet Mill is needed to produce pellets from palm fiber or palm silk. The Tricks of making high quality EFB pellets is at the material preparation side. Appropriate material preparation with suitable pellet making machine, there will be no problem in pelleting EFB. Specification of EFB Pellets Length: < 30mm Diameter: 6, 8 & 10mm

Make EFB Pellets with EFB Pellet Mill

- Raw Material: cottonseed oil

- After-sales service: Field repair and maintenance service

- Voltage: 380V

- Press series: Third

- Transportation package: Fumigated wooden boxes

- Specification: 1250*690*1140mm

EFB pellet making The crushed EFB powder that contains proper moisture will be fed into the pellet mill and pressed into solid EFB pellets with high density. EFB pellets cooling and packing The pellets just come out from the pellet mill are hot, so they must be cooled first. Then they can be packed in small or large bags as needed. EFB pellets

High return EFB pellet plant. The key tech of the palm EFB production is the pre-processing system and the EFB biomass pellet mill. RICHI is always committed to supplying simple and economical EFB pellet making solutions. Comparing with the conventional palm EFB pellet processing, we simplify the the production process.