Sunflower Oil Production Line for Sunflower Oil Plant to

- Type: sunflower oil plant

- Usage/Application: sunflower

- Production capacity: 1tpd-30tpd

- Voltage: Design according to customer demand

- Weight: Standard

- Dimension (L*W*H): 4935*1523*2664

- Power ( W): 11 KW

- Country: zimbabwe

50T/D Edible Oil Production Plant; 30T/D Edible Oil Production Plant; 10-20T/D Edible Oil Production Line; 1-50T/D Edible Oil Production Line; Oil Refinery Plant. Large Continuous Edible Oil Refinery Plant 20-5000TPD; Batch-type Edible Oil Refining Equipment 1TPD to 20TPD; 10T/D Edible Oil Refinery Plant; 1-5T/D Edible Oil Refinery Plant

How Is Sunflower Oil Made? (The Step-by-Step Process)

- Type: sunflower oil processing machine

- Warranty: 2 years

- Voltage: 380 V

- Customized: Customized

- Press Series: First Class

- Press Materials: Vegetable Oil Seeds

Sunflower oil is made by pressing the seeds of the sunflower plant. This process extracts the oil from the seeds and then it is refined, bleached and deodorized in order to purify it. After this process, the oil is ready for consumption and can be used for cooking or as a supplement.

Sunflower seed oil is obtained from the seeds within the brown hub in the center of the sunflower plant. Sunflower oil is light in taste and gives more Vitamin E than any other vegetable oil. Sunflower oil is mainly composed of less-stable polyunsaturated and monounsaturated fatty acids, it can be most susceptible to degradation by heat, air

Sunflower Seed Preparation and Oil Extraction - ScienceDirect

- Usage: sunflower oil

- Production capacity: 1-200T/D cooking oil refining machine

- Voltage: 380-660V, 380-460V

- Weight: 1050 KG of cooking oil refining machine

- Dimension (L*W*H): 1610x615x1260mm of cooking oil refining machine

- Power: 2.2 KW

Sunflower seed processing focuses on sunflower oil as the most valuable product. It is used as high-value oil in various food applications. The deoiled meal is considered a byproduct and is mostly used as animal feed. In 2011, annual world production of deoiled sunflower meal was at 16 million tons (FAO, 2013). The deoiled meal composition

USDA Reports: USDA Logo Follow the links in the right-hand navigation to review the status of oil and non-oil plantings for the top producing states in the country. The tables include information on acres planted, harvested, yield per pound per acre, and production per 1000 pounds for the current and most recent years.

How is Sunflower Oil Processed?

- Type: cooking oil extraction machine

- Production capacity: 98%

- Power (W): 22 kW Dimension (L*W*H) : 48m*12M*15M(30TPD)

- Voltage: 220V/380V/440V

- Weight: 30 tons

- Application range: Types of seeds

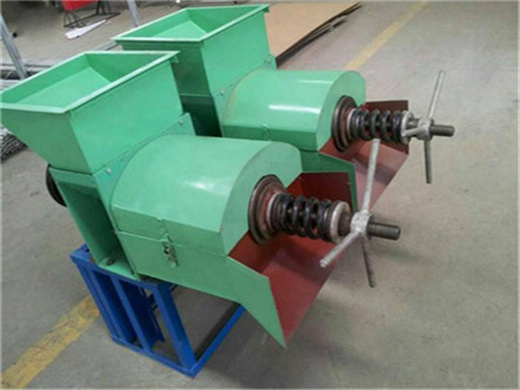

Small Scale Sunflower Oil Processing Line. Sunflower oil processing involves many process that will decide the equipment and machinery for a sunflower oil processing plant. For small scale sunflower oil processing line, the equipment may be relatively simple and easy to operate. Of course, the investment cost for small scale oil factory is low

It is a high-grade nutrient oil. Set Up Small Sunflower Oil Production Line (1-20ton/day) Small Scale Sunflower Seed Oil Production Line - mini oil mill. Production Output: 1-20ton/day; Main Equipment: Cleaning/screening machine, seeds cooker, oil expeller, oil filter press and conveyors.

From Seed to Bottle: The Fascinating Journey of How Sunflower

- Raw Material: sunflower

- Production capacity: 40-50kg/h

- Dimension (L*W*H): 1200*800*1160mm

- Voltage: 220V/380V

- Weight: 250kg

- Residual oil proportion: 1%

Join us on a mesmerizing journey as we take you behind the scenes of the sunflower oil production process, from the vast sunflower fields to the high-tech plants where the magic truly happens. In

Wide application of Sunflower Oil Production. Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system