Akyurek Group Technology - Seed Processing Equipment

- Type: cottonseed oil processing machine

- Usage/Application: cottonseed

- Production capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Weight: 1050 KG

- Dimension (L*W*H): 1610x615x1260mm

- Power (W): 10-50kw

- Country: mozambique

Our expertise lies in developing innovative machines and systems that address the challenges encountered during and after the harvesting of these agricultural products. Our products successfully separate unwanted materials (such as dust, stones, soil, straw, glass, etc.) from dry vegetables, grains, pulses, seeds, and oilseeds.

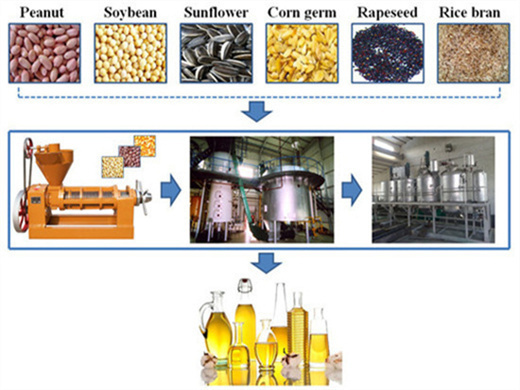

Steps of Cottonseed Oil Processing Process - Oil Mill Machinery

- Type: cottonseed oil processing machine

- Production capacity: 100% oil extract

- Voltage: 220V/380V/440V

- Weight: 1000 kg

- Dimension (L*W*H): According to its capacity, according to the capacity

- Power(W): 11KW

In this section we use Magnetic Separator, Vibrating Sieve, de-stoner, decorticator (Cotton seeds used hammering decorticator). Through cleaning the impurity, you can reduce the lost of oil & improve the oil yield and the environment of production plant. The material has been produced after pretreatment contains the impurities ≤ 0.1%.

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

Complete Cotton Seed Oil Processing Plant

- Usage: cottonseed oil

- Production capacity: 100% hydraulic cooking oil extraction motor

- Voltage: 220V/380V

- Weight: 1000KG

- Dimension (L*W*H)): 900*850*1550mm

- Power (W): 1.5 kW

The pre-treatment equipment used in cotton seed oil pressing plant for cottonseed includes cleaning equipment (magnetic separator, cleaning screen and destoner), sheller, shell separating screen, embryo flaking machine, steam frying pan or cooking machine, and a series of other equipment. Next, the cotton seed oil pressing machine are used to

Seed Processing Equipment for Grains, Pulses, and Oilseeds Mmctech offers industrial-grade seed processing equipment designed for cleaning, grading, sorting, polishing, drying, and separating a wide range of seeds and grains. Our machines ensure high efficiency, precise results, and scalability for commercial operations.

Cottonseed Oil Extraction Plants: A Blueprint for Sustainable

- Type: cooking oil extraction machine

- Production capacity: 20-2000T/day

- Power (W):15KW

- Voltage:380V

- Dimension (L*W*H):standard

- Weight: 30 tons

Explore the significance of cottonseed oil extraction in the food industry and agriculture. Discover the detailed process, essential equipment, and environmental impacts of cottonseed oil extraction plants. Gain insights into the economic benefits, challenges, and future trends shaping this industry. Learn how by-products are utilized and recommendations for sustainable development.

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Cottonseed Oil Mill / Oil Extraction Plant Manufacturers

- Raw Material: cottonseed oil

- Plate Type: Flatbed Printer

- Color and Page: single color

- Auto Grade: Automatic

- Voltage: 220V/50HZ

- Dimensions (L*W*H): 1300x800x1450mm

The requirement of machinery and equipment for Cottonseed Oil Mill usually depends on the various aspects such as processing raw materials, required pressing capacity, production cost budget and other detailed information. So don’t hesitate to get in touch with us to get a customized business plan and project cost list. Here we have listed

Cottonseed oil production is rife with challenges, though. The fluffy white fibers and abrasive hulls can be difficult to separate from the oil-rich kernels; the seeds also contain a toxic substance called gossypol that processors must deactivate. Without the right equipment, cottonseed processing can cause a mess and can even pose a safety hazard.