Multi-functional Automatic Small Oil Press Machine for

- Type: cottonseed oil press machine

- Usage/Application: cottonseed

- Production capacity: 99.9%

- Voltage: 220 V

- Key selling points: Long service life

- Weight: 10KG

- Dimension (L*W*H): 360*150*310 mm

- Country: uganda

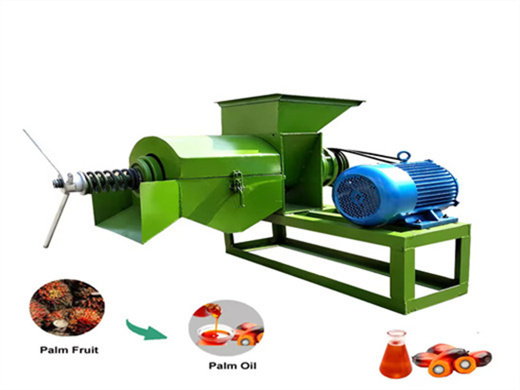

Our Machinery designs and manufactures high quality Commercial Oil Press Machine, including single screw oil press and automatic multi-functional oil press machine for all types of oilseeds. Besides, we have also provide complete turnkey project services for small, medium and large scale cooking oil manufacturing plant at low cost for clients

Seed Oil Press Machines for Sale-Industrial Oil Press

- Type: cottonseed oil processing machine

- Production capacity: High

- Voltage: 380 V

- Main components: pressure vessel, gear, master

- Weight: 5500

- Dimension (L*W*H): 2900*1850*3640 mm

ZY24(202-3) type pre-pressing machine’s large capacity, small workshop area, low power consumption, less operation management and maintenance work make it suitable for squeezing sunflower seed oil in large vegetable oil plant.

Our Small oil press can be used for various raw materials, such as peanuts, soybeans, rape seeds, cotton seeds, sesame seeds, sunflower seeds, jatropha seeds, canola seeds, coconut seeds, tea seeds and palm seeds. Gemco considers technological innovation as the cornerstone of its development.

Cotton Seed Oil Press, Professional Oil Press Manufacturers

- Usage: cottonseed oil

- Press Series: Second

- Customized: Customized

- Transportation package: in wooden packaging, according to customer specifications: various

- Raw material: sunflower, kitchen, etc.

- Function: Edible Oil Making

The 6yl screw seed oil press is a mini oil extraction plant that has gained great popularity in the global cottonseed oil extraction market. It is a versatile machine that can extract oil from various oil plants, such as cotton seeds, coconut, soybean seeds, peanut kernels, rapeseeds, and more.

A cold cotton seed oil press is an oil extraction machine that uses hydraulic oil to pressurize and transmit pressure through an oil pump. The cold-pressed cottonseed oil has good oil quality, high oil yield, does not generate temperature during the cold-pressing process, does not destroy the organic components of the oil, and contains fewer

Premium Automatic Cotton Seed Oil Extruder Machine for Sale

- Type: cooking oil extraction machine

- Production capacity: according to capacity

- Power (W): according to capacity

- Voltage: 220v,380v,440v

- Dimension (L*W*H): 1610x615x1260mm

- Weight: 1050 KG

The YZS series automatic oil press is an advanced cotton seed oil extruder which is developed on the previous single oil press machine according the market demands. It has strengthen the function of frying and automatic controlled temperature, which has changed the traditional way for increasing dry cake's temperature, therefore it reduced the working time, and also reduced the waste of power

We supply a great number of seed oil making machines including cotton seed oil expeller and automatic oil press for other plant seeds. We also offer turnkey solutions for complete set of oil mill plant, capacity ranging from 1 TPD to 6000TPD. Feel free to tell us your oil manufacturing needs and we will help you make the best plan!

Factory Price Cotton Seed Oil Mill Machine for Sales | ABC

- Raw Material: cottonseed oil

- Production capacity: 1-500TPD

- Power (W): According to its capacity

- Voltage: 220V, 380V

- Certification:ISO9001 & CE

- features: high performance, good quality Portable Oil Refinery

Cotton Seed Oil Processing Machine (1~20T/D) Different from traditional screw oil press, our cotton seed oil machine is available with heating device. Therefore, you have the choice to save preheating time of the machine itself. More importantly, it can greatly improve the oil output as well as quality of crude cotton seed oil.

Brief Overview of Cottonseed Oil Production Line. 1. The cottonseed oil production process is advanced, with full consideration of low cost, energy saving, environmental protection, and thermal energy recovery and reuse. 2. The process can achieve fully automated control. 3.