Palm Oil Machine - Palm Oil Production Line

- Type: palm oil refinery machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 100%

- Voltage: Local voltage

- Weight: 880kg

- Dimension (L*W*H): 2000x1400x1850mm

- Power (W): Capacity

- Country: kenya

Henan Hongde Cereals and Oils Machinery Co., Ltd. has been focusing on the research and development and manufacturing of palm oil processing machine for more than 37 years, providing a full set of solutions from palm fruit pressing to palm oil refining. Palm oil machinery cover different scales of processing from 10 to 1,000 tons per day(TPD

Palm Oil Production Line - Oil mill

- Type: palm oil refinery machine

- Production capacity: 80-150Kg/h

- Voltage: 380V/50HZ

- Main components: motor, PLC, bearing

- Weight: 780 KG

- Dimension (L*W*H): 1700* 1200*1500 mm

The Batch type is the ideal choice for small-sized palm oil production (1-20TPD), while the Semi-continuous Refinery plants are the best choices for middle-large size production lines (20-50TPD), a fully continuous refinery line(50-600TPD) is most used in large palm oil production plants.

Hongde Oil Machinery is a leading company in the field of palm oil pressing and palm kernel oil processing and equipment, we can provide completely set of 5-120tph palm oil production line. Our company offers a range of products and services for the palm oil extraction, palm kernel oil extraction, crude palm oil refining and complete palm oil

Complete Palm Oil Production Line

- Usage: palm oil

- Production capacity: 98%-100%

- Voltage: 380V/50HZ

- Weight: 10 tons

- Dimension (L *W*H): 48m*12M*15M(30TPD)

- Power (W): 22kw

Henan Hongde Cereals and Oils Machinery Co., Ltd. has been rooted in grain and oil equipment manufacturing for 37+ years. It has a modern production base of 100,000 square meters, equipped with cutting-edge equipment such as laser cutting machines, fully automatic welding robots, CNC precision machining centers, and an annual production capacity of more than 200 large-scale edible oil

Sterilization as the first step in palm fruit pressing is critical to the quality of the final production-- palm oil. The purpose of sterilization process is, inactivate the activity of lipase and prevent the rise of free fatty acids; make the palm fruit easier to fall off from the fruit bunch; and soften the peel and make the oil easier to separate out.

Palm Oil Refining Processing Machinery - Find Edible Oil

- Type: cooking oil refining machine

- Voltage: Adjustable

- Residual solvent in finished food: ≤ 300PPM (qualified detonated experiment)

- Certification: ISO CE

- Steel type: carbon steel or 304 steel

- Moisture of finished food: ≤ 10-13% (adjustable)

Physical palm oil refinery plant is featured of high efficiency, simple production process and low effluent load. Chemical Refining of Palm Oil; In the chemical refining process, the FFA is removed by neutralisation with caustic soda (sodium hydroxide). This chemical reaction produces neutralised CPO and a soap stock.

Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

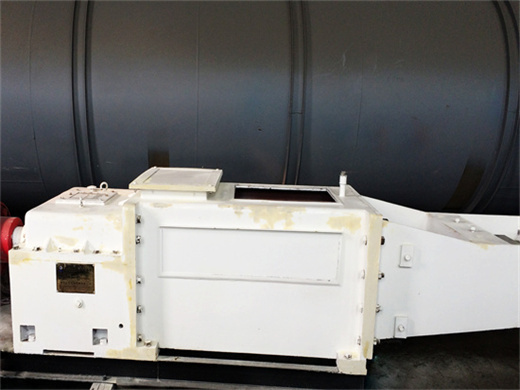

Finished installation palm oil refinery plant for DRC kenya

- Raw Material: palm

- Press Series: Second

- Production Automatic press Grade: Automatic

- Customized: Customized

- Weight: 160- 1700 kg (depends on model)

- Material: Carbon steel Q235

Palm oil refinery plant is very populary in Africa. Our DR kenya customers bought our 30t/d palm oil refinery plant in July 2012. Now already finished installation, it is already put into production.

The six processes of palm oil refining machine. palm oil refining equipment to remove harmful substances at the same time, but also better preservation of oil in the Vitamin A and Vitamin E and other nutrients, to improve the quality of palm oil. 2024-08-07