Valorization of an agroindustrial soybean residue by

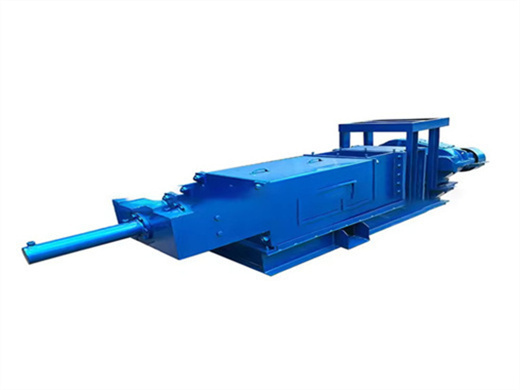

- Type: soybean oil extraction machine

- Usage/Application: soybean

- Production capacity: 150-300 kg/h

- Voltage: 220v/380v/Customer request

- Main components: Motor

- Weight: 1100 KG

- Dimension (L*W*H): 1900* 1400*1700mm

- Country: lesotho

The effectiveness of scCO 2 and its use along with EtOH as modifier for the extraction of bioactive compounds with antioxidant activity from two soybean expellers (residues from pressing oil extraction) was evaluated. Extractions curves for both samples at different conditions (temperature, use of glass beds, use of EtOH) were made.

Chemical characterization of liquid residues from aqueous

- Type: soybean oil processing machine

- Voltage: 380V

- Power (W): according to capacity

- Certification: CE and ISO

- Weight : modified with capacity

- Dimension (L*W*H)): various with capacity

12% SDS-PAGE profile of total protein of the liquid residue from the extraction of soybean oil through enzyme processing carried out at pH 4 (A) or at neutral pH (B). Lane 1: sample without enzymatic treatment; Lanes 2, 3 and 4: samples treated with AVLpH – Alcalase and Viscozyme; Lanes 5, 6 and 7: samples treated with ACLpH – Alcalase

Olive oil extraction. An olive mill and an olive press from the Byzantine period in Capernaum. Olive press in Jerash, Jordan (20th-century) Frail (pressing basket), used in pressing the olive pulp. Olive oil extraction is the process of extracting the olive oil present in olive drupes. Olive oil is produced in the mesocarp cells, and stored in

Main Factors Affecting Residual Oil Content in Soybean Meal

- Usage: soybean oil

- Voltage: 220V/380V

- Power (W): 22kw

- Certification: ISO,CE,BV

- Weight: 3000KG

- Dimension (L*W*H) : 2600*1300*2300mm

2. Extraction Section. During the extraction process, the factors affecting the residual oil content in soybean meal are extracting temperature, extracting time, the purity of solvent, and the amount of solvent. 2.1 Extracting Temperature. The solvent used in the current extraction industry is mainly n-hexane, and its distillation range is 66

After leaching, the concentrated mixed oil with high oil content can be obtained, and the residue content in the mixed oil is also small. But the extraction time is longer. Soaking and spray mixed:At first, soak the material embryo and spray the permeation, which improves the extraction rate and the oil production efficiency, and reduces the

(PDF) Supercritical Extraction of Soybean Residues - Academia.edu

- Type: cooking oil extraction machine

- Production capacity: according to capacity

- Power (W): according to capacity

- Voltage: 220v,380v,440v

- Dimension (L*W*H): 1610x615x1260 mm

- Weight: 1050 KG

Highlights Soybean residues from pressing oil extraction are a source of phytochemical compounds. Valorization of these residues was achieved by using green scCO2 extraction processes. Optimal extraction conditions were 40 MPa and 35°C for

Soybean (SB) solid residue after oil extraction was investigated in a hydrothermal modification process to provide an eco-friendly solution to SB solid waste disposal for an actual environmental management effort. SB hydrochars (HCs) were derived either by conventional heating hydrothermal treatment …

Pyrolysis of soybean residue: Understanding characteristics

- Raw Material: soybean

- Production capacity: 10T-100T/D

- Power (W) : 11KW

- Voltage: 220V/380V

- Dimension (L*W*H): According to the actual situation

- Weight: 1000 kg

Soybean is an important oil crops cultivated widely worldwide [1]. Soybean residue (SR) is the main by-product from oil extraction and soymilk/tofu manufacturing. Approximately, the cold pressed (control) single pressed soybean residue have the highest residue yield of 87.17% [2, 3].

Flaking: The cracked soybeans are then flattened into flakes, which increases the surface area for oil extraction. Cooking: The soybean flakes are heated to a specific temperature to enhance oil extraction efficiency. Pressing: The heated flakes are subjected to high pressure in mechanical presses, squeezing out the oil from the flakes.