henan cottonseed oil direct solvent extraction plant in ivory

- Type: cottonseed oil refinery plant

- Usage/Application: cottonseed

- Production capacity: 5TPD

- Voltage: 380V/440V

- Warranty: 3 years

- Weight: 300TON

- Dimension (L*W*H): 12m*18m*10m

- Country: rwanda

ABC Machinery have engaged in designing and establishing oil mill plant for almost 20 years and have registered more than 30 patent licenses. We can offer complete equipment for cooking oil extraction and refinery, encompasses the entire production process, including seed pre-cleaning and pre-heating equipment, oil press, oil filtration machinery, and oil refining plant. You are welcome to contact us for detailed information about our machinery or the cost of starting edible oil manufacturing business!

Cottonseed Oil Mill Plant

- Type: cottonseed oil refinery machine

- Production capacity: 5TPD-100TPD

- Voltage: 110/220v 60/50hz

- Oil type: Cooking oil

- Main components: Motor

- Dimension (L*W*H): 46*18*29 cm <br /Weight: 10.5 kg

Undecorticated Cottonseed obtained after Delinting process can be used as a raw material for Cottonseed Oil Extraction Plant. Cottonseed contains 18 – 20 % oil content. After a single stage pressing, about 6 – 7 % residual oil is left in the cottonseed meal which is an excellent source of Cattle Feed. The working principle of the cotton

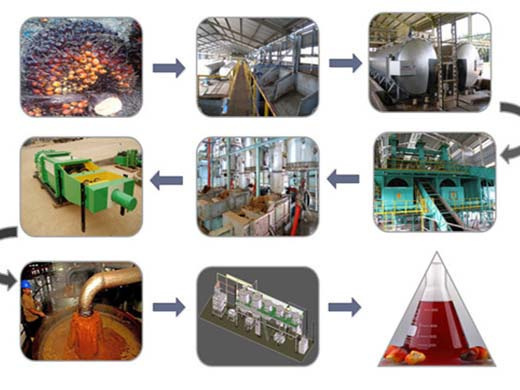

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

Cottonseed Oil Processing - Oilmillmachinery.net

- Usage: cottonseed oil

- Voltage: 380 V

- Power (W):Standard

- Certification:CE,ISO

- Weight:Standard

- Dimension (L*W*H):Standard

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

Cottonseed kernels contain 0.5%-2.5% of gossypol. After processed by the cottonseed oil refinery plant, the gossypol content in the oil is less than 0.01%. The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1.

50-500 tons cotton seed oil refiner with design in liberia

- Type: cooking oil refining machine

- Appearance: Screw

- Press Series: First

- Press Materials: Sunflower, etc.

- Customized: Not customized

- Carrying package: Plastic film

GOYUM provides complete solution for Cottonseed Oil Refinery Plant, capacity to design, build and supply plants from 5 - 30 TPD Batch Type & 50 - 500 TPD Continuous Type Refinery. Cottonseed Oil Refinery Plant Process: Degumming with Double for Crude Cotton Seed Oil Neutralization - Efficient Removal of hydratable and non-hydratable

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

cotton seed oil mill project report

- Raw Material: cottonseed oil

- Production capacity: 96% ~ 98%

- Dimension (L*W*H): 3800*2320*3800 mm3

- Voltage: 380V/50Hz

- Weight: 9000 KG

- Warranty: 1 year, 12 months

Cottonseed Oil Refining Plant. Cottonseed mixed oil refining is to degum and deacidify the mixed oil (the mixture of solvent and oil) gained from the first vaporization system in cotton seed extraction technology before it is not totally evaporated and desolventized, and before its viscosity and density are lower than crude oil.

Features of Cotton Seeds Oil Refinery Plants. 1. Wide application: Various kinds of oil can be refined by our oil refining machines, especially cotton seeds. 2. Multifunction: Including degumming, neutralization, bleaching, deodorization and dewaxing (optional). 3. No need for a specially designed workshop.