Physical and Chemical Process in Palm Oil Refining Plant

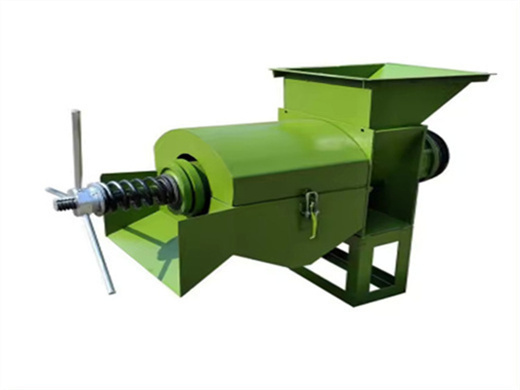

- Type: palm oil refinery equipment

- Usage/Application: palm fruit, palm kernel

- Production capacity: 98%

- Voltage: 220V/380V/440V

- Weight: 1200kg

- Dimension (L*W*H): 1700*1100*1600mm

- Power (W): 1.5kw

- Country: lagos

The palm oil and palm kernel oil are steamed at a temperature of 240°C to 260°C to get away the odors and tastes, and then they are cooled into room temperature (about 55°C) for further use. This process have great impact on the quality of the final palm oil and palm kernel oil. Crude Oil Chemical Refining Plant

Environmental (#34) Palm Kernel Oil - ERASM

- Type: palm oil refinery machine

- Production capacity: 98-99%

- Voltage: 380v or customize

- Main components: Motor

- Weight: 760 KG

- Dimension (L*W*H): 2000*1350*1750mm

in the palm oil mill, palm kernel oil mill and in the refinery process (degumming, bleaching and de‐acidification and deodorization stage). Global Warming Potential (GWP): An analysis of the inventory data showed that the main contribution comes from cultivation on peat land.

We can provide the palm oil refinery plant from 1 ton to 1000 tons. In general, batch type palm oil refinery plant is with capacity 1-20TPD; The semi-automatic palm oil refinery plant is suggested with capacity from 20-50TPD; And continuous palm oil refinery plant is used for capacity above 50TPD. Of course, this is just an option, not necessary.

Palm oil physical refining vs palm oil chemical refining

- Usage: palm oil

- Production capacity: 1TPD-1000TPD

- Voltage: 220V/380V

- Weight: 280 kg

- Dimension (L*W*H): 3120*830* 1500 mm

- Power: 7.5kw

Chemical refining: If the daily processing capacity is about 5-30 tons of palm refining, you can choose to use batch refining equipment for chemical refining. Small and medium-sized palm oil refinery plants have low cost, small investment and simple operation. The above is an introduction to the process of physical refining and chemical

The main purpose of chemical refining is to remove the FFA by an alkaline solution and at the same time remove other impurities.This chemical refining of palm oil can be used for refining almost all crude vegetable oils, such as soyben oil, peannut oil, cottonseed oil, rapeseed oil, sunflower oil, palm kernel oil and so on.

Palm oil refining equipment

- Type: cooking oil refining machine

- Production capacity: 50 -3000 TPD

- Power (W): As production of sunflower edible oil refining machine every day

- Voltage: 380v 440v

- Dimension (L*W) *H):As production of sunflower edible oil refining machine per day

- Weight:Depends on the production of the edible oil refining machine

Solutions for palm oil refining 1, Crude palm oil filtration process The purchased crude oil needs to be filtered to remove suspended particles and other impurities before the following production can be carried out. 2, Palm oil refining and degumming process Main process flow:

Physical palm oil refinery plant is featured of high efficiency, simple production process and low effluent load. Chemical Refining of Palm Oil; In the chemical refining process, the FFA is removed by neutralisation with caustic soda (sodium hydroxide). This chemical reaction produces neutralised CPO and a soap stock.

Palm Kernel Oil Refining - Palm Oil Mill Machine Leading

- Raw Material: palm

- Production capacity: 20-2000TPD

- Power (W): standard

- Voltage: 380V

- Dimension (L*W*H): standard

- Weight: standard

Palm kernel oil contains soap grade and food grade.The process of Palm kernel oil refinery is to refine the crude edible oil, to remove gossypol, protein, phospholipid, grume, moisture and other impurities, in order to reach the purchase of food and storage.The process of palm kernel oil refinery includes mechanical refinery method, chemical

Alkali Neutralization; Adds the mixture of liquid caustic soda (1.5% of crude palm kernel oil weight and with 160 baume) and the liquid sodium salt (0.5% of the crude palm kernel weight) into the crude palm kernel oil, then stir it rapidly at the speed of 60 r/min for about 10 to 15 minutes, and followed by the stirring slowly at the speed of 27 r/min for 40 minutes.