Soybean Oil Making Machine

- Type: soybean oil machine

- Usage/Application: soybean

- Production capacity: 10T-3000T/D

- Voltage:220V/380V/440V

- Weight:According to oil refining capacity

- Dimension (L*W*H):1200*400*900mm3

- Power ( W): 10-50kw

- Country: nairobi

Components of a Soybean Oil Making Machine 1. Soybean Cleaner: - Purpose: To remove impurities such as stones, dust, and other debris from the soybeans before processing. - Function: The cleaning machine typically uses air blowers, sieves, and magnets to ensure only clean soybeans are processed, which improves the efficiency of oil extraction. 2.

300TPD Soybean Oil Processing Machines Equipment

- Type: soybean oil processing machine

- Production capacity: 50-500 kg/h

- Voltage: 220V/380V or customized

- Main components: motor, pressure vessel, bearing

- Weight: 220kg

- Dimension (L*W*H): 1200* 780*1100mm

The separated solvent vapour is cooled and recycled back to the extractor for reuse, which can improve the solvent efficiency. Negative Pressure Evaporation Advantages: Vacuum evaporation features high efficiency, thorough de-solvation and low solvent consumption in crude oil.

Mechanical pressing typically yields 70-80% of the oil content from soybeans. 2. Solvent Extraction Machine: In large-scale soya oil production, solvent extraction is used to recover nearly all of the oil. A solvent like hexane dissolves the oil from the soybean cake left after pressing, ensuring a higher yield of up to 99%. 3.

Soybean Oil Extraction Machine - Buy Soybean Oil Extractor

- Usage: soybean oil

- Production capacity: 1-2000TPD

- Voltage: 220V

- Weight: 1300kg

- Dimension (L*W*H): 46*32 *36cm

- Power (W): 5.5 kW

New type soybean oil extraction technology utilizes solvent to extract oil out of soybean embryos through effects of wet penetration, diffusion and convert diffusion. The solvent capable of dissolving the fat separates soybean oil from the mixture of oil and solvent, and obtains crude soybean oil after solvent recycled.

The extraction method has a higher oil yield, and because the solvent can extract the oil from the soybean cells, the oil is extracted more thoroughly. However, the crude oil may contain solvent residues, so the required refining conditions are more stringent than those of the pressed oil.

Soybean oil press Machine | Soybean oil extraction machine

- Type: cooking oil extraction machine

- Press Materials: Crude Oil

- Custom: Custom

- Press Series: Second

- MOQ: 1

- Transportation Package: Standard Export Packing

The soybean enters the press chamber from the hopper of the soybean oil extraction machine, and the soybean is continuously pushed inward by the press screw. Under the condition of high pressure in the press chamber, there is a great friction resistance between the material embryo and the press screw, and between the material embryo and the

Main features of soybean oil manufacturing machine 1. High-efficiency production: - Modern soybean oil manufacturing machines can achieve continuous and efficient production processes, with a daily processing capacity of several tons to hundreds of tons, greatly improving the speed and efficiency of oil extraction.

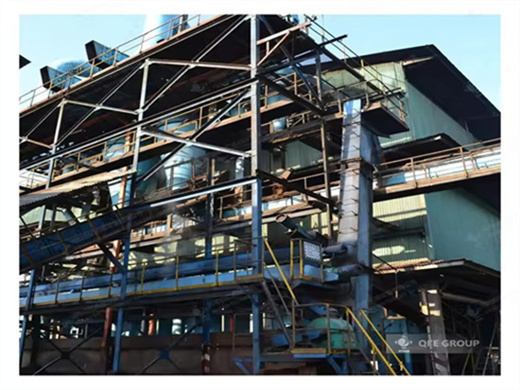

Soybean Oil Extraction Machine - Myande Group

- Raw Material: soybean

- Press Materials: All Seeds

- Custom: Custom

- Press Series: Second

- Features: Small hydraulic oil press

- Hot press and cold press: Both available

During the whole soybean oil processing process, the soybean oil processing machine plays a very important role. Without the soybena oil processing machine, we couldn't get the final crude soybean oil, refined soybean oil. The whole set soybean oil processing machine is composed of soybean oil pretreatment and pre-pressing machine, soybean oil solvent extraction plant and soybean oil refinery plant.

Soybean oil extractors are essential machines in the oil production industry, offering flexibility, efficiency, and reliability in extracting oil from soybeans. Their wide range of applications, from food processing to biodiesel production, makes them crucial in both small and large-scale industrial contexts.