Step-by-Step Guide to Set Up a Palm Oil Mill Plant

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 1-2000TPH

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

- Power ( W): 18.5 KW

- Country: nigeria

Investing in a palm oil mill plant can diversify investment portfolios and secure long-term financial stability. Typical Steps to Setup A Sucessful Palm Oil Milling Plant. 3D FLow of Palm Oil Processing Factory Setup . Setting up a palm oil mill plant involves a series of carefully planned steps to ensure a smooth and successful operation.

Low Cost Mini Palm Oil Mill Plant for 1-10 ton Production Line

- Type: palm oil processing machine

- Production capacity: 10T-5000TPD

- Voltage: 220V/380V/440V

- Weight: 2T-20T

- Dimension (L*W*H): 2500mm*2000mm*3000mm

- Power (W): 10kw-50kw

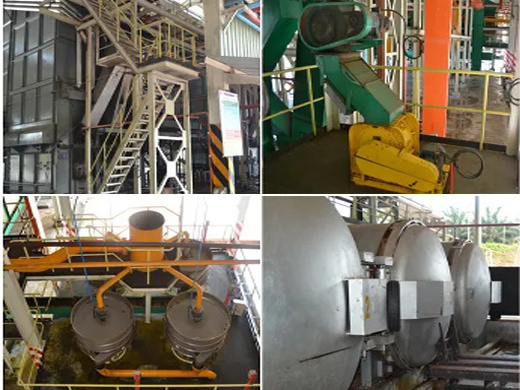

Equipment List for 10TPD Mini Palm Oil Milling Process. For 1-10 ton per day palm oil production, the crane is not equipped in most cases. The crane is used for lifting the palm fruits. In mini scale palm milling factory, this job usually done manually. View the photos below to see what the complete equipment looks like.

One is mini palm oil mill plant for 1~10 ton/day factory, and the other one is 10~20 ton/day palm oil milling plant for small and medium-sized factory. Main Processing Equipments for Crude Palm Oil Mill Plant. The main equipment for small palm oil mill is palm fruits cooking and sterilizing tank, FFB Stripper and screw palm oil press machine

Palm Oil Production Line. Tailor-made Palm Oil Mill Plant

- Usage: palm oil

- Production capacity: 10T-3000T/D

- Voltage:220V/380V/440V

- Weight:According to processing capacity

- Dimension (L*W*H):1200*400*900mm3

- Power (W): 10-50kw

This 500 kg/h Fresh Fruit Palm Oil Mill is a compact and efficient solution for small-scale palm oil production. Designed for farms, cooperatives, and small oil processing businesses, this mill provides a complete solution to extract crude palm oil from fresh fruit bunches (FFBs) with minimal labor and time investment.

Palm oil mill design and operation involve multiple engineering calculations requiring numerous data and formulas. This first edition of the 'Palm Oil Mill Pocketbook' provides a quick reference

Highly Efficient Palm Oil Milling Process for Palm Oil Mill

- Type: cooking oil extraction machine

- Production capacity: 1-2t/h

- Dimension (L*W*H): 2500x1220x1100mm

- Voltage: 220V 380V

- Weight: 1000kg

- Raw material: Palm fruit

A palm oil milling process plant produces crude palm oil and kernels, as primary products and biomass as secondary product. The capacity of mills varies between 60- 100 tons FFB/h. A typical mill has many operation units as shown in the picture below.

Hongde oil machinery can provide a whole palm fruit/palm kernel oil mill plant production line for you, if you have a lot of palm fruit to process, you can contact with us. We can offer you a whole line of palm oil pretreatment equipment, palm oil extraction machines, and palm oil refinery machines, and build a palm oil turnkey project from A

Palm Oil Mill | PDF | Motor Oil | Lubricant - Scribd

- Raw Material: palm

- Production capacity: 1t/day-1t/hour-100%

- Dimension (L *W*H): 1055 *805*345mm

- Voltage: 220V/50HZ three-phase

- Weight: 27.1 KG

- Main components: Motor, Motor

The document describes the process for producing crude palm oil from palm fruit. It involves several steps: depericaping to separate palm fruit from fibers, drying nuts in silos, cracking nuts using rollers, separating kernels from shells using screens and hydrocyclones, drying and storing kernels, and treating effluent from the process before discharge. The overall objective is to produce

Palm Oil Fractionation Plant - 10-500T/D Capacity, Automated Oil Processing Equipment | High Liquid Oil Yield, Advanced Fractionation Technology, Suitable for Multiple Oil Types Price : 2000 USD ($) Palm Oil Extraction Machine - Dual Screw Helix System | First Grade Edible Oil Machinery for 99.99% Purity, Suitable for Multiple Raw Materials, 10