Sunflower Oil Refinery Plant Process - Oil Expeller

- Type: sunflower oil refinery equipment

- Usage/Application: sunflower

- Production capacity: 200 kg/h-2000 kg/h

- Voltage: 380V/415V three-phase

- Local Service Location: Nigeria

- Weight: Depends on capacity

- Dimension (L*W*H): depends on Capacity

- Country: uganda

In this stage the neutral oil is mixed 10% to 12% hot water with a short duration mixture and separated through the centrifuge. The soap traces will be removed. The neutral and washed oil will be send to tank. At this stage the oil temperature will be maintained at 85 – 90°C. The Neutral oil contains less than 50ppm of soap. Vacuum Drying

PHYSICAL REFINING OF SUNFLOWER OIL

- Type: sunflower oil refinery machine

- Appearance: Horizontal

- Press materials: Sunflower, soybean, coconut, peanut, mustard

- Size: 2005*1610*2010 mm

- Processing capacity: 8 tons/24h

- Customized: Customized

Sunflower oil has a high nutritional value, having 62-70% linoleic acid content (essential fatty acid) but on the other hand this high polyunsaturated fatty acid content makes this oil sensitive to oxidation. Crude sunflower oil, which has reached a certain level of oxidation is difficult to refine. There are two main difficulties: 1.

Start Crude Sunflower Oil Refining Plant. Introduction to Sunflower Oil Refining Steps. The refining process of sunflower seed oil mainly includes several stages: pretreatment, degumming, deacidification, decolorization, deodorization, and dewaxing.(Relaed Article: Sunflower Oil Refinery Plant Cost>>) Flow Chart - Sunflower Oil Refining Process

What are the main components of sunflower oil refining equipment?

- Usage: sunflower oil

- Production capacity: 150-2500 KG/h

- Place of Voltage: 220/380/400V

- Weight: 60000KG

- Dimension (L*W*H): 15*12*12

- Power (W): 260KW

The main components of sunflower oil refining equipment for batch include oil refining tank, decolorization tank, filter, vacuum system and heat transfer system. In the batch sunflower oil refining process, raw oil is first stored in refining tanks and impurities and fatty acids are removed through a degumming process.

We at Tinytech Udyog offer small scale to medium scale Sunflower Oil Refinery Plants on Turnkey basis. We design and develop complete integrated refinery plant and system specially for sunflower oil. Sunflower oil is considered to be one of the most stable oils for frying.

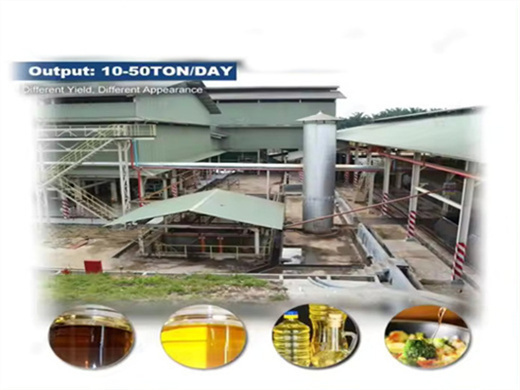

Oil Refinery - Edible Oil Refinery Technology and Equipment

- Type: cooking oil refining machine

- Voltage: 380V/50HZ

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Power (W): 22kw

- Weight: 10 tons

- Certification: CE ISO

Equipment: Bleaching earth feeder,Pre-mixer ,Bleaching tank,filter,Bleaching vacuum system Features:The oil from neutralization section is mixed with bleaching earth for removal of pigments. The bleaching earth is transported in pneumatic mode, thus efficiently alleviate environment pollution caused by dust.

The composition of sunflower oil refining machine. A complete set of sunflower seed oil refining equipment is composed of a variety of equipment and parts. It mainly consists of an alkali solution tank, degumming and deacidification tank, filter, decolorization oil tank, vacuum deodorization equipment, supporting pipe, tank, oil pump, etc.

Sunflower Oil Making Machines for Sale

- Raw Material: sunflower

- Voltage: 220V/380V/440V

- Dimension (L *W*H): 5432*2636 *2345

- Power (W): depends on capacity

- Weight: 850 KG

- Certification: ISO9001

You are welcome to inquire about the project details and costs of our sunflower oil extraction machine and refinery machine! 10 ton/d sunflower oil processing plant in Moldova; 150 ton/d sunflower oil manufacturing plant in Russia; Sunflower Oil Making Process. Sunflower oil manufacturing is a complex process involving various stages.

Sunflower Oil Refinery Plant. Sunflower Oil Refining Process. Sunflower seed oil has a light color. The degumming, deacidification, decolorization and deodorization process of sunflower oil processing are basically similar to soybean oil refinery plant. But sunflower oil usually generally needs dewaxing process to reach the national standards