PALMINDO

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 7-8 TPD

- Voltage: 60 HP

- Main components warranty: 5 years

- Weight: 4000 KG

- Dimension (L*W*H): 2641MM *1016MM*2489MM

- Country: pakistan

Physical refining is one of the methods that used for edible oil refining. This process removes phospholipids, pigments, off-flavours, free fatty acids and other impurities in the crude oil. Our unit is suitable for both crude palm oil and palm kernel oil. Our physical refinery plants are built in state of art technology and large scale production.

Small Scale Palm Oil Mill Plant, Equipmentfor 1-20t/d Production

- Type: palm oil processing machine

- Production capacity: 8~10 ton/day

- Dimension (L*W*H): 8.53*5.41*8.69 ft

- Main components warranty: Others

- Warranty: One year warranty against manufacturer's defect.

- Weight: 3500 KG

Small scale palm oil mill plant generally refers to the palm oil processing production with the capacity below 20 ton per day. We have two small palm fruit processing solutions for your! One is mini palm oil mill plant for 1~10 ton/day factory, and the other one is 10~20 ton/day palm oil milling plant for small and medium-sized factory.

Fractionation Plant. Our process technology is based on a fully continuous and automatic fractionation of palm oil. An exclusive technique of gravitational membrane filtration is implemented in palm oil fractionation that aids in better olein recovery on a sustained basis with a higher recovery chance.

fully automatic palm oil plant mantin in botswana

- Usage: palm oil

- Production capacity: 20-1000T

- Voltage: 380V/220V

- Weight: up to oil extractor machine

- Dimension (L*W*H): up to specification

- Power ( W): up to specification

It provides a detailed analysis of. 1ton per hour big full automatic palm oil processing plant. Palm oil mil process of drying: continuous Vacuum drier with the oil out of the water, the water can be reduced to 0.1%. 9.Palm oil mil process of depericarper (splitter): through floating dry processing the fruit core and fibers separated.

A research on the fertigation effect on palm oil growing on medium black soils in Karnataka in India concluded that NPK applications in oil palm cultivation of 1200:600:1200 vs. 300:150:300 g/plant/year boosted fresh fruit bunch yields Reddi, Sanjeevraddi & H.P, Maheswarappa & Chandravathi, B & Patil, D. (2016). Effect of fertigation on yield

Palm oil milling equipment and machinery - Alfa Laval

- Type: cooking oil extraction machine

- Production capacity: seed processing machinery

- Voltage: 380V, depends of capacity

- Weight: depends on capacity

- Dimension (L *W*H): depends on capacity, depends on capacity

- Power (W): 5.5 kW

For decades, Alfa Laval has worked closely with palm oil mills in the development of reliable, efficient solutions for converting palm fruit into crude oil. Today our palm oil milling equipment can be found throughout the oil room. Designed with over a century of separation technology expertise, we offer state-of-the-art decanter and disc stack centrifuges optimized for mills, as well as

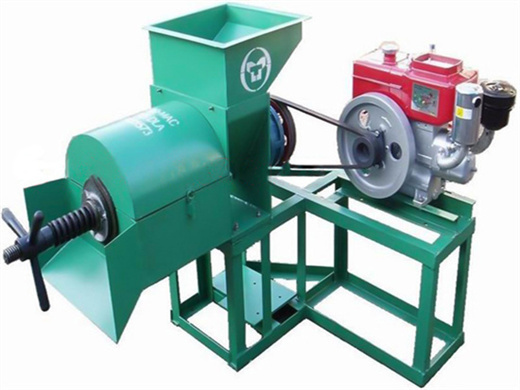

Single Palm Oil Press Machine Price: Referring to single screw pressing type of palm oil processing machine, a small oil press is generally priced at around $2,000.00 - $3,000.00, while for complex palm oil press machine for industiral oil mill plant, with a main motor of 18.5 kW and have a packing dimension of 255 x 170 x 205 cm, the price is

Complete Palm Oil Mill Plant Layout Design

- Raw Material: palm

- Production capacity: 98%-100%

- Power (W): 22kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 2000x1400x1850mm

- Weight: 10 tons

Meet the Requirements of Palm Oil Production Process; The designing of palm oil mill plant should fully take the features of palm oil production into consideration, including the palm oil production process, raw materials and final products transportation tools and methods, etc. Select the Factory Structure Reasonably

Three Steps to Start Your Own Medium-Sized Palm Oil Plant Business According to the construction plan of medium-sized palm oil refinery, there are three stages: Stage 1: Preparation 1. Construction Cost of Medium Palm Oil Refinery Price levels are different in each country and region, it is determined mainly according to local conditions. 2