Screw Oil Processing Plant For Peanut Sesame in south africa

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Voltage: 220 V, 380 V

- Power (W): According to its capacity

- Features: cooking oil plant

- After-sales service provided: Engineers available to repair machinery abroad

- Certification: CE, BV & ISO9001

- Country: south africa

We are a professional Peanut/Groundnut Oil Production Machine Manufacturer in China. Our company is dedicated to the design, installation, commissioning and technical training of peanut oil processing plant for 36+ years; we can provide a complete set of groundnut oil production machine turnkey projects with a processing capacity ranging from 10-5000 tons per day.

(PDF) Defatting and Defatted Peanuts: A Critical Review on

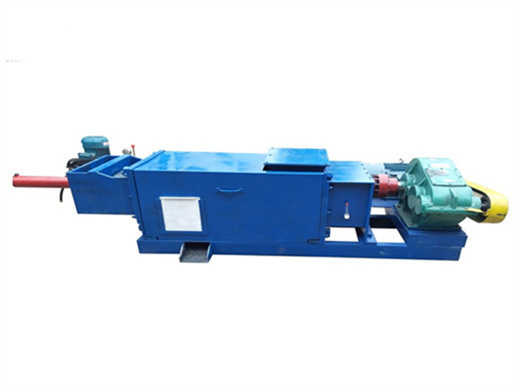

- Type: peanut oil processing machine

- After-sales service: Provided

- Structure: Horizontal

- Processing capacity: 150kg/H

- Voltage: 380V

- Press Series: Third

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

The residue or leftover of peanut oil production is known as peanut oil cake. High oil output rate. The oil yield of a groundnut oil extractor can reach about 50%. The dry cake residue rate is less than or equal to 8%. High efficiency. Our peanut oil expeller can process 500 kg of raw materials per hour. And only one person can operate the machine.

Libya Good Performance Cold Press Oil Extractor in south africa

- Usage: peanut oil

- Production capacity: 60%

- Voltage: 220V/380V

- Main components: Motor

- Weight: 760 KG

- Dimension (L*W*H): 1200*780*1400mm

Volume 7. Issue 4 ───. 649. Cold press method; simple to use, environment-friendly and fatty seeds ar e the most. commonly used method in t h e oil f ield, but its ef fi ciency is low while. The VI-20000 (A) is a specialized Cold Oil Press Machine with a built-in heater, designed for premium cold-pressed oil extraction on an extra-large

Recommended reading: Peanut oil processing plant. Peanut oil pretreatment and pressing machine. Although the peanut pretreatment machine is necessary, the peanut oil press machine is also important. As the core equipment of the peanut oil pressing production line, peanut oil press machine plays a huge role in the whole peanut oil pressing process.

Peanut oil extraction plant for sale_vegetable oil extraction

- Type: cooking oil extraction machine

- Production capacity: 10-1000MT

- Power (W): 1.5 kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 1400 *600*600 mm

- Weight: 700 kg

Ⅱ、Extraction section of the sunflower oil extraction plant. Extraction section is to extract peanut oil by suitable organic solvent, this method can get the highest oil yield rate. After peanut oil solvent extraction plant , the residual oil rate in cake is less than 1%. Peanut oil solvent extraction process flow chart are as follows:

To commercially extract cold-pressed peanut oil, a twin-screw press is used, and the pressing is performed at specific temperatures that do not exceed 60 °C. The oil yield was not evaluated in this study, but the researchers were very interested in utilizing the by-product of this extraction (i.e., the meal), knowing that 70 kg of PDPM was

Peanut Oil Processing Technology - ScienceDirect

- Raw Material: peanut

- Production capacity: 100% vegetable oil refining machine

- Power (W): 22kw

- Voltage:220V/380V/440V

- Dimension (L*W) *H):48m*12M*15M(30TPD)

- Weight:30 tons

The leaching procedure mainly makes use of the solid-liquid extraction principle to select certain fat-dissolving organic solvents to extract the peanut oil. Generally speaking, the leaching solvent should meet the following conditions: good fat solubility, stable physiochemical properties, easy separation from the fat and meal, and be safe

Peanut oil (groundnut oil), as a kind of light yellow transparent edible oil with a pleasant fragrance and good taste, is relatively easy to digest. Peanut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid).