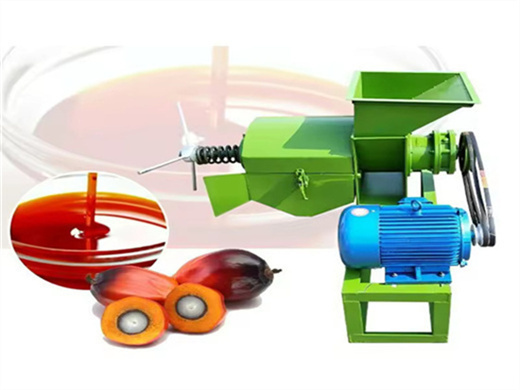

Palm Kernel Oil Plant - Oil Expeller. Edible Oil Production Line

- Type: palm oil refinery plant

- Usage/Application: palm fruit, palm kernel

- Production capacity: 5TPD

- Voltage: 180-240V, 50-60HZ

- Main components warranty: 3 years

- Weight: 70 KG

- Dimension (L*W*H): 54.5x29x71cm

- Country: nigeria

Palm Kernel Oil Refining . Like other oil seeds refining process, palm kernel oil refinery has to follow four steps which are degumming, neutralization, decoloring and deodorizing. 1. At degumming section, hot water is used here as materials like phospholipids and gums are soluable in oil but not in water.Thus the impurities are separated.

Crude palm kernel oil refinery process

- Type: palm oil refinery machine

- Production capacity: 20 kg/h

- Voltage: 180 V-240 V

- Main components: Motor

- Weight: 72 KG

- Dimension (length x width x height). ): 70*45*65 CM

Mini palm oil refinery plant, 2tpd palm oil refining machine video with voice explanation. Indonesia 5tpd palm oil refinery plant successfully installed video. Small scale palm oil fractionation plant video. Palm oil filter equipment - plate and frame filter presser. Peru 20tpd batch type olive oil refinery plant video

This 500 kg/h Fresh Fruit Palm Oil Mill is a compact and efficient solution for small-scale palm oil production. Designed for farms, cooperatives, and small oil processing businesses, this mill provides a complete solution to extract crude palm oil from fresh fruit bunches (FFBs) with minimal labor and time investment.

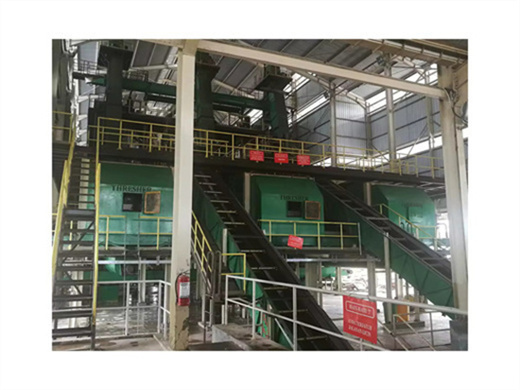

Palm Kernel Oil Production Line, Plam Kernel Oil Production Plant

- Usage: palm oil

- Voltage: 380 V

- Power (W):Standard

- Certification:CE,ISO

- Weight:Standard

- Dimension (L*W*H):Standard

Palm Kernel Processing Plant Customized for You. According to different production capacity and customers’ different requirements on the products, our company can make rational choice and combination of palm kernel oil production processes, choose the best technological process, as well as sophisticated equipment manufacture and automatic control system to provide customers with perfect

The dried kernels are often sold to palm kernel crushers for extraction of crude palm kernel oil. In some integrated plants, kernel crushing facilities exist side by side in the same complex. Palm Oil Mill Processing Line Palm bunch reception is the primary processing of crude palm oil processing machine.

Palm Kernel Oil Refinery

- Type: cooking oil refining machine

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 3750*850*1990MM

- Voltage: 220V/380V

- Weight: 1800KG

- Warranty: 1 year, 12 months

The oil composition of palm kernel oil is very different from that of the palm oil. Apart from the normal crude palm kernel oil, there are other 2 types of components obtained after palm kernel oil refining – 1) Palm Kernel Olein. This is the liquid component of the palm kernel oil obtained after refining. 2) Palm Kernel Stearin

Palm oil /palm kernel oil refining is based on different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substances in the crude palm oil/palm kernel oil, getting standard palm oil/palm kernel oil.

Physical and Chemical Process in Palm Oil Refining Plant

- Raw Material: palm

- Material: stainless steel

- Grade of the oil: 1st, 2nd, 3rd

- Request for engineers: 1-2 engineers

- Environmentally friendly: yes

- Business Warranty: 12 months

The palm oil and palm kernel oil are steamed at a temperature of 240°C to 260°C to get away the odors and tastes, and then they are cooled into room temperature (about 55°C) for further use. This process have great impact on the quality of the final palm oil and palm kernel oil. Crude Oil Chemical Refining Plant

Hongde Machinery provides optimal palm oil mill plant layout and design for all palm oil mills or factories, from small-scale to large-scale. What’s more, you can also find palm oil complete machines and refinery machinery in our company to fulfill your business ambitions. If you are interested to know more about factory layout for palm oil industry, please feel free to contact us any time. Below is our contact details.