Soybean oil production process in a edible oil plant

- Type: soybean oil plant

- Usage/Application: soybean

- After-sales service: Technical support

- Warranty: 12 months

- Press materials: Sunflower, All seeds

- Appearance: Horizontal

- Voltage: 380V

- Country: south africa

If yes, join us to unveil the fascinating soybean oil extraction process. Have you ever wondered how modest soybean seeds become nutritious and delectable edible oils? .gatsby-image-wrapper noscript [data-main-image]{opacity:1!important}.gatsby-image-wrapper [data-placeholder-image]{opacity:0!important}

Soybean Processing Basics: Operations - NOPA

- Type: soybean oil processing machine

- Production capacity: 3.5kg-600kg/h

- Voltage: 220V/110V

- Weight: 11kg, 11kg

- Dimension (L*W*H): 46*19*24 cm

- Power (W): 450-700W

of a soybean as it journeys through a processing plant to become meal and oil. Soybean Cracks Whole Soybeans Soybean Hulls Soybean Hull Pellets Soybeans received from farmers and local elevators for processing. Soybeans cracked into small pieces to aid in hull removal and preparation for flaking. Excellent source of fiber for animal feed

From the raw seed through all stages of processing, we provide a complete solution for the oilseed processing industry. The most common seeds include soybean, canola/rapeseed, sunflower, palm and corn. If you have another seed that contains oil, we can customize equipment just for you. We’ll take the guesswork out of processing.

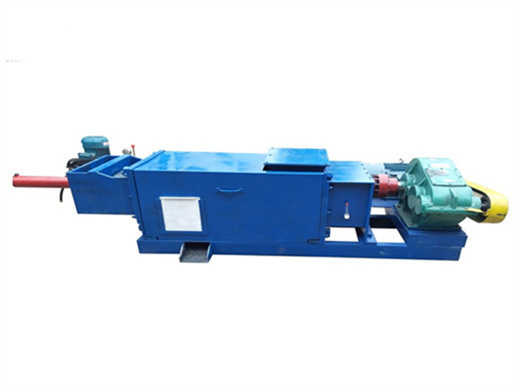

Soybean Oil Extraction Plant Project

- Usage: soybean oil

- Production capacity: 100ton/day

- Voltage: 380v

- Main components: Bearing, Motor, Gear, Gearbox, Motor

- Weight: 5000 KG, 5000Kg

- Dimension (L*W*H): 2850*1850*3270

As the demand for soybean oil continues to grow, more and more investors are interested in the soybean oil extraction machine business and want to make profits by opening soybean oil extraction plants. As an edible oil processing equipment manufacturer that has helped many domestic and foreign customers successfully establish soybean oil

Soybean Oil Production Process. The production of commercial soybean oil is complicated. Below are the main steps of the soybean oil production process. Cleaning Section of Soybean Oil Production: The soybeans are first cleaned, dried and dehulled prior to oil extraction. The soybean hulls needs to be removed because they absorb oil and give a

SOYBEAN PROCESSING FLOWCHART - NOPA

- Type: cooking oil extraction machine

- Production capacity: 5-2000TPD

- Dimension (L*W*H): up to specification

- Voltage: 380V/50HZ

- Weight: 2000 KG

- Main components: motor, pressure vessel, pump, PLC, gear, motor, gearbox

SOYBEAN PROCESSING FLOWCHART MAP OF PROCESSING PLANTS LOOSE, GROUND, OR PELLETED HULLS OIL DISTILLATION GRINDING NOTE: The National Oilseed Processors Association (NOPA) represents the U.S. soybean, canola, ˜axseed, sun˜ower seed and sa˚ower seed crushing industries. This ˜owchart is an illustrative diagram of standardized steps employed in

Soybeans are the dominant oilseed in both U.S. and world markets. During a typical year soybean production comprises over half the worldwide oilseed production (Anonymous 1995). However, according to Dutton (1981) in the early 1940s, soybean oil was considered a poor...

Soybean Oil Production Line, Soybean Oil Extraction Plant Project

- Raw Material: soybean

- Voltage:380V/three-phase

- Dimension(L*W*H):1200*400*900mm3

- Power(W):According to your capacity

- Weight:According to your capacity

- Certification:CE and ISO

Soybean Oil Application. 1. In Food Industry. Liquid soybean oil is sold as “vegetable oil” or as a component of processed food like margarine, shortening, mayonnaise and various flavoring oils. The refined soybean oil is pale yellow, clear, transparent, odorless, and has a good taste. It can be used for cooking without foam and smoke.

For those reasons, refined soybean oil is widely used all over the world. Production of high quality meal and crude oil is the main objective in soybean processing. For achievement, thorough knowledge of the te chnical system and disciplined operation are required. The starting point is reception of soybeans at the processing plant.