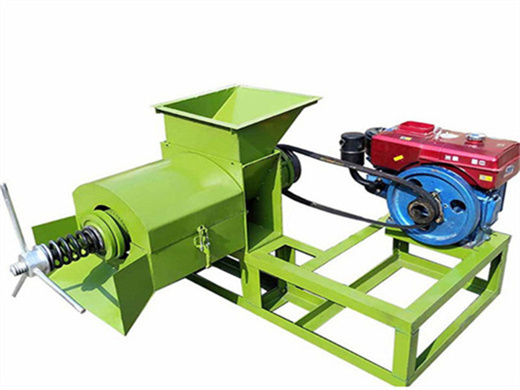

Mini Soybean Oil Processing Unit

- Type: soybean oil processing machine

- Usage/Application: soybean

- Main components: motor

- Oil Raw material: argan oil argan/sunflower/peanut oil/sesame/capsicol

- MOQ: 1 set

- Function: Oil press

- Material: stainless steel

- Country: uganda

Suitable Oil Plants for the Mini Edible Oil Processing Unit: This mini oil processing unit is capable of pressing various kinds of oil-bearing materials and oil plants, including soy, sesame seeds, corn seeds, sunflower seeds, cotton seeds, rapeseed, groundnut kernels and so on. The equipment composition may be different for extracting oil

Soybean Oil Processing Business Startup Cost and Project

- Type: soybean oil processing machine

- Production capacity: 5TPD-100TPD

- Voltage: 110v-220V

- Warranty: 1 year, 1 year

- Weight: 8 KG

- Dimension (L*W*H): 375*160*275mm

Soybean Oil Processing Plant Cost Soybean oil production business can be started from mini or small-scale oil mill plant since it requires lesss investment cost. The small soybean oil processing plant designed by Our Machinery, with capacity 5~20 tons per day may need at least $7,500. But the final exact cost should be confirmed with your sales

Mini Oil Processing Line. Benefits of Building a Mini Soybean Oil Mill Plant. First, this mini soybean oil plant is user-friendly and not labor-intensive. For your information, you can ably operate the plant with a workforce of two to three people only. The operating environment of the plant is safe. Secondly, you can set up the unit hassle-free.

How to Start Mini Soybean Oil Mill Plant | 1~30 Tons/Day

- Usage: soybean oil

- Production capacity: 1tpd

- Voltage: local voltage

- Main components: motor, pressure vessel, pump, PLC, others, gears, bearings, motor, gearbox

- Weight: 6 KG

- Dimension (length*width*height): about 8.2*2*4.2m

1~30TPD Mini Soybean Oil Mill Plant. Mini Soybean Oil Mill Plant at Low Cost. Soybean oil processing requires a series automatic process. Normally, the basic process of mini soybean oil processing plant is cleaning, cooking, oil pressing, oil filtration or oil refining, etc.. Every process has the respective soybean oil processing equipment to

Soybean Oil Extraction Process. Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.

Manufacturer of soybean oil processing plant

- Type: cooking oil extraction machine

- Production capacity: 95%

- Power (W): 10-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 1200 *400*900mm3

- Weight: According to the cooking oil processing capacity

We focus on providing customers with efficient and energy-saving soybean oil processing equipment. The main products include screw oil presses, solvent extraction equipment, refining equipment, etc., covering the complete production chain from soybean pretreatment, oil pressing to oil refining.

The following pictures shows some of the soybean oil processing plants. Soybean oil is an edible oil with a light and clean flavor that is commonly used for cooking. The oil is 60% polyunsaturated fat and 24% monounsaturated fat, according to the National Soybean Research Laboratory, making it a heart-healthy oil. Soybean oil is extracted by

Soybean Oil Processing Plant - IMARC Group

- Raw Material: soybean

- Production capacity: 6-8 kg/h

- Dimension (L*W*H): 430*150* 220mm

- Voltage: 220 V/110 V

- Weight: 7.7KG

- Warranty: 1 year

IMARC Group’s report titled “Soybean Oil Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a soybean oil processing plant. It covers a comprehensive market overview to micro-level information such as unit

Main features of soybean oil manufacturing machine 1. High-efficiency production: - Modern soybean oil manufacturing machines can achieve continuous and efficient production processes, with a daily processing capacity of several tons to hundreds of tons, greatly improving the speed and efficiency of oil extraction.