Palm Oil Production Process: A Step-by-Step Guide

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Voltage: 380V/220V or as required

- Dimension (L*W*H): 2700*820*1400mm

- Main components: Motor

- Main components warranty: More than 5 years

- Weight: 1800KG

- Country: uganda

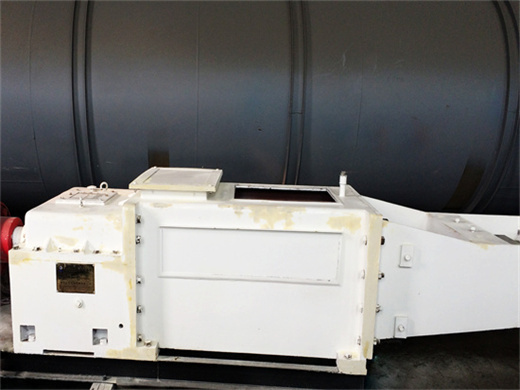

The palm oil plant installed in africa.this project adopts the horizontal sterilizer tank sterilizing craft, which can effectively reduce the residual oil rate and improve the output of refined oil compared with other forms of sterilizing . The project is equipped with high-pressure boilers and steam turbine generators, using fuels such as fibers and shells produced in the production. Combustion power generation supplies electricity to the plant; adopts automated electrical controls reduce labor costs and increase productivity.

Complete Palm Oil Mill Plant Layout Design

- Type: palm oil processing machine

- Production capacity: 1-100T/DAY

- Voltage: 220V/380V

- Main components: Others

- Weight: 8100kg

- Dimension (L*W*H): 950*1100*1450mm

Palm Oil Mill Plant Layout Design. Palm oil production processes are completed in the palm oil processing plant. The layout design of palm oil processing factory is very important to increase the oil production capacity and lower the operational cost. The requirements for palm oil mill factory designing includes. Meet the Requirements of Palm

Palm oil is a kind of vegetable oil derived from the mesocarp of the fruit of the oil palm tree (Elaeis guineensis). Saturated and unsaturated fatty acids rich, it is semi-solid at room temperature and extensively used in food, cosmetics, and biofuels because of its oxidative stability, long shelf life, and high hectare yield.

A plant design for mechnaical extraction of PKO

- Usage: palm oil

- Production capacity: 1-2000TPD

- Voltage: 220V/380V/440V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850 mm

- Power (W): 7.5 kW

palm oil, which is obtained from the flesh of the fruit. The design objective in this case is to redesign and fabricate a palm kernel oil extraction plant (mechanical) that will produce 200kg of palm kernel oil per day using palm kernel. In the extraction of palm kernel oil, many processes are involved namely: Traditional, solvent extraction and

In addition to medium and large palm oil extraction plant, we can also customize different daily processing capacity of small scale palm oil production lines for small business, such as: 1 ton/hour, 2 tons/hour, 3 tons/hour, 5 tons/hour, etc. Small scale palm oil extraction plant include six steps: threshing, sterilization, digestion, pressing, crude oil clarification and filtration, all of

DESIGN AND FABRICATION OF A PORTABLE PALM KERNEL EXTRACTOR

- Type: cooking oil extraction machine

- Sample: 10 ml

- MOQ: 5L

- Appearance: Light Yellow

- Fragrance: Custom Scent

- Form: Liquid Flavor Concentrate

Is to design and fabricate a portable palm kernel oil extraction plant that willproduce 100kg-200kg of palm kernel oil per day using palm kernel and to reducewaste and improve the efficiency and output of palm kernel. This can only be * achieved by mechanizing the palm kernel oil extraction processes over the manual process of

This new version of the handbook takes into account the latest developments in milling and processing activities. It incorporates the latest technologies for better oil extraction and the recent

Palm Kernel Oil Mill Project | PDF | Petroleum | Warehouse

- Raw Material: palm

- Production capacity: 1t/day-1t/hour

- Dimension (L*W*H): 2100*750 *1500mm

- Voltage: 110v/220v/380v

- Weight: 800 KG

- Main components: bearing, motor, gearbox

This document provides details on a proposed palm kernel oil mill project, including: 1. The project will establish a processing complex with a 10 metric ton per hour palm kernel oil expeller mill and facilities for storage, processing infrastructure, and utilities. 2. The turnkey project work will be divided into three stages - initial assessment, detailed engineering design, and supervision

The cake emerges from the end of the press (Gbadamosi, 2006). In this research work, the design and construction of a palm kernel oil extraction machine was carried. Parameters such as efficiency, processing time, and machine throughput 23 Oyejide et al. (2018). Design and Construction of a Palm Kernel Oil Extraction Machine.