Palm Kernel Oil Extraction - Palm Oil Mill Machines

- Type: palm oil extraction machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 30TPH-120T/H

- Voltage: 220V/380V

- Weight: depends on capacity

- Dimension (L*W*H): depends on capacity

- Power (W): depends on capacity

- Country: zimbabwe

Palm kernel oil pressing. Palm kernel oil pressing processing line is simple with usual oilseeds. The pre-pressing by oil pressing machine can obtain 1/4 palm kernel oil, and residual oil need twice pressing. Palm kernel Filtering section: after pressing, there are some oil dregs in the crude oil, after clarifying, we need to filter the crude

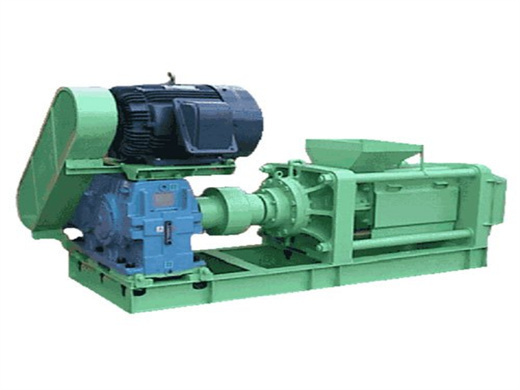

Palm Kernel Oil Extraction Machine

- Type: palm oil processing machine

- Production capacity: 45%

- Voltage: 380 V

- Main components: Motor

- Weight: 1100 KG

- Dimension (L*W*H): 1700*1400*1850

Basic Unit Operations of Palm Kernel Oil Extraction Process: 1. Palm Kernel Pre-treatment; 2. Oil Extraction; 3. Solvent Recovery From Oil and Meal; The following is the main advantages of palm kernel oil extraction machine and plant: 1. Fit for mass production of Palm Kernel Oil Extraction Machine; 2. High oil extraction rate, low oil residual

DOING GROUP is a leader manufacturer of palm oil machine, here you can see palm oil refinery machine detials, palm oil extraction machine installation information,palm kernel oil refinery line, and project reports of crude palm oil refinery machine,palm oil mill plant etc.

Palm Oil Machine - Palm Oil Production Line

- Usage: palm oil

- Production capacity: 100%, 5T-200T per hour

- Voltage: 380V/50HZ, 380V/440V or local voltage

- Weight: 1200kg, According to capacity

- Dimension (L*W*H): 1700*1100*1600mm, According to capacity capacity

- Power (W): 15KW, According to capacity

Hongde Oil Machinery is leading professional manufacture and supplier of palm oil production line equipment includes palm fruit oil press, palm kernel oil extraction machine, CPO Refinery, and palm oil fractionation plant. Our team offer turnkey production solution for complete palm oil processing project with competitive cost!

Palm kernel oil is extracted from the seeds of the oil palm tree, primarily found in tropical regions. The extraction process involves several stages harvesting the fruit, separating the kernels from the pulp, and then milling the kernels to extract oil. The efficiency and quality of this process are significantly influenced by the machinery

Palm Kernel Oil Solvent Extraction Line

- Type: cooking oil extraction machine

- Production capacity: 80%

- Dimension (L*W*H): 1200*780*1400 mm

- Voltage: 220V/380V

- Weight: 1000 KG

- Warranty: 1 year, 1 year

Hongde’s palm kernel oil pressing and extraction production line can flexibly adjust the process according to the characteristics of the palm kernel: For palm kernels with high shell content, the kernel-shell separation link is strengthened, and multi-stage vibrating screens and wind sorting devices are added to control the shell residue residue rate below 3%; If the moisture content of the

Palm Kernel Oil Extraction Process. Palm Kernel Oil Extraction Process. Palm Kernel Cleaning: Palm kernel cleaning is mainly to remove iron wire, stone, fiber and other impurities in palm kernel. These impurities are easy to damage the machine, especially the palm kernel oil press machine. Palm Kernel Crushing: Generally, the palm kernel needs

palm oil line

- Raw Material: palm

- Production capacity: 500 kg/h

- Dimension (length x width x height): 2600 x 2100 x 1730 mm

- Voltage: 220 V/380 V

- Weight: 1200 kg

- Main components: engine oil Material: Stainless steel

After palm oil expelling, the solids parts discharged from the screw press is mixture of fiber and nuts. In palm kernel recovery plant, the nuts and fiber are separated by physical means. The nuts are sent to palm kernel crushing and solvent extraction plant to make palm kernel oil, while the fiber is used as biomass fuel in boiler on-site.

How the Palm Kernel Oil Extraction Machine Works. Palm kernels move from the hopper into the extraction chamber to be crushed. A rotating screw powered by the motor forces the kernels through the chamber and breaks them down into smaller pieces. The friction from the rotating press screw adds to the high temperature in the chamber.