Professional Sunflower Seed Oil Processing Plant for Both Big

- Type: sunflower oil plant

- Usage/Application: sunflower

- Voltage: 380 V/50 HZ

- Power (W): 15 KW

- Certification: ISO

- Weight: 1200kg

- Dimension (L*W*H) : 1700*1100*1600mm

- Country: afghanistan

They differ in oleic levels and each one offers unique properties. Sunflower oil that is processed by our sunflower oil processing plant meets the needs of consumer and food manufacturers alike for a healthy and high performance non-transgenic vegetable oil. Available sunflower seed varieties fall into two major groups: confectionery and oilseed.

Sunflower Oil Production Plant Process Flowchart - GOYUM GROUP

- Type: sunflower oil processing machine

- Production capacity: 100TPD

- Voltage: 220/380

- Main components: motor, pressure vessel, Pump, PLC, Gear, Bearing, Motor, Gearbox, Others

- Weight: 280 KG

- Dimension (L*W*H): 1400*860*1260

Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system, the goodness of sunflower oil can help take

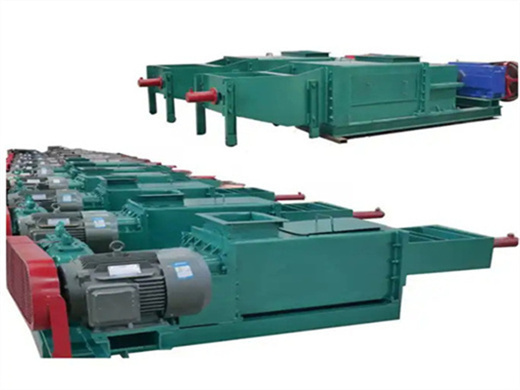

The purpose of grinding is to increase the surface area to be heated during extraction. Sunflower Oil Extraction; The heated sunflower seeds meal is continuously added to the sunflower oil making machine that has slotted barrel at highly progressing pressure from 69000 to 200000 kilopascals. The oil is squeezed out and recovered through the

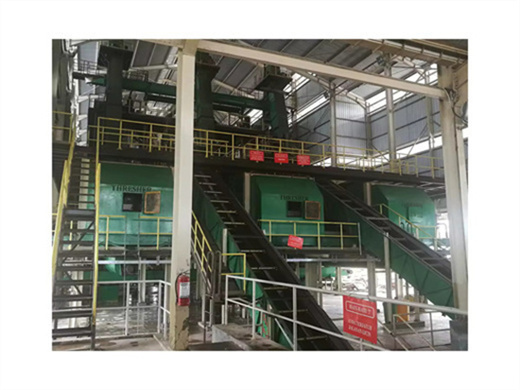

Oil Extraction Plants

- Usage: sunflower oil

- Production capacity: 42-52%

- Voltage: 110v/220v

- Main components: motor

- Weight: 9.3 KG

- Dimension (L*W*H)): 48x20x30cm

The company has products such as the screw oil press machines, solvent extract plants, oil-milling plants among others. (Read More: Tanzania Sunflower Oil Making Machine >>) When purchasing sunflower oil processing equipment products from the KMEC Company, one is guaranteed to get the best of quality. The sunflower oil will not be compromised

In the whole sunflower oil production line, sunflower seeds should be shelled, cleaned, cooked, and pressed. a sunflower oil solvent extraction plant is used to achieve a high oil yield. Through the sunflower oil solvent extraction process, the oil residue will be less than 1%, and the meal will be more suitable for animal feed. The final

How to extract sunflower oil from sunflower seeds?_Tech

- Type: cooking oil extraction machine

- Production capacity: 20-2000T/day

- Power ( W): 11KW

- Voltage:220V/380V/440V

- Dimension (L*W*H): 1.5*2.6*3.6M

- Weight:0.5-10T

But the sunflower seeds also need pretreatment, and only the capacity is more than 30 tons per day, the engineers of Henan Doing Company will recommend the sunflower oil solvent extraction plant. The process of making refined sunflower oil in sunflower oil refinery plant. The making process flow chart of sunflower oil refinery plant. The

The sunflower seed contains 35 – 40 % oil content and double pressing is required to extract maximum oil, 9 – 11 % residual oil is left in the sunflower meal which is an excellent source of Animal Feed.

What Are 5 Steps of Edible Oil Solvent Extraction Plant Process

- Raw Material: sunflower

- Production capacity: 1-100T/DAY

- Dimension (L*W*H): 1230*1120*1630mm

- Voltage: 220V/380V, 380V

- Weight: 1800 KG

- Main components: Motor, cooking oil processing machine

For high oil content oilseeds like cottonseed, rapeseed, peanut, sunflower seeds, etc., before oil solvent extraction, the cooking oil making machine is used to extract 85% to 89% of the oil within the oilseed, and the resulting oil cake is crushed into a certain size, and then for solvent extracting to obtain leached crude oil.

The following are the sunflower seed oil processing links within a sunflower oil plant. Sunflower Seeds Pre-Cleaning The first thing to do is to clean sunflower seeds and remove impurities from them. We can use magnets to remove metal impurities from raw materials. Then, screening was conducted to remove other impurities that might affect