Palm Oil Mill Plant Production Line - QI'E Group

- Type: palm oil refining line

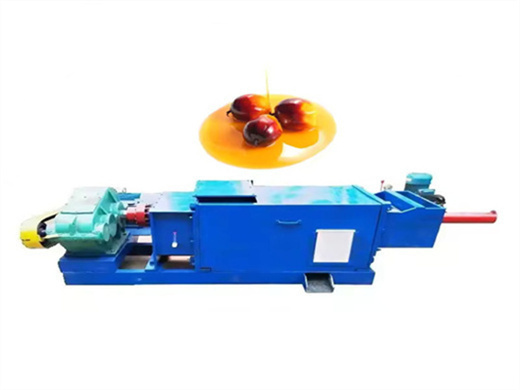

- Usage/Application: palm fruit, palm kernel

- Production capacity: 30kg/h

- Voltage: 380V (can be customized)

- Main components: Motor

- Weight: 5100kg

- Dimension (L*W) *H): 800*720 *1180mm

- Country: lusaka

The oil refining process is suitable for refining soybean oil, rapeseed oil, sunflower oil, palm oil ,cottonseed oil and etc. QI'E GROUP is a large - sized joint - equity enterprise which is specialized in producing edible oil mechanical equipment. Palm Oil Mill Plant Production Line is our unique patented technology equipment. With more than

Complete Palm Oil Production Line

- Type: palm oil refinery machine

- Type of product:Fruit oil

- Type of processing:Refined

- Use:Kitchen

- Type of crop:COMMON

- Type of refining:Fractional oil

Henan Hongde Cereals and Oils Machinery Co., Ltd. has been rooted in grain and oil equipment manufacturing for 37+ years. It has a modern production base of 100,000 square meters, equipped with cutting-edge equipment such as laser cutting machines, fully automatic welding robots, CNC precision machining centers, and an annual production capacity of more than 200 large-scale edible oil

The main palm kernel oil refinery process is: crude palm kernel oil degumming neutralization decolorization deodorization process. During palm kernel oil refinery process, we adopts water hydration degumming, alkali neutralization or steam distillation deacid, adsorbent activated clay or activated carbon decolorization, high temperature

PALM KERNEL OIL REFINING

- Usage: palm oil

- Production capacity: 30T/H

- Voltage: 380v to 440v

- Weight:According to capacity of oil refinery

- Dimension (L*W*H) :According to capacity of oil refinery

- Power (W): According the capacity of oil refinery

Palm kernel oil contains soap grade and food grade.The process of Palm kernel oil refinery is to refine the crude edible oil, to remove gossypol, protein, phospholipid, grume, moisture and other impurities, in order to reach the purchase of food and storage.The process of palm kernel oil refinery includes mechanical refinery method, chemical

Mechanical pressing can typically extract up to 45-50% of the oil content. Equipped with the automatic temperature-controlling device and crude oil filter tank, Our integrated screw oil press operates easily and has high oil output. After pressing, the crude palm kernel oil is filtered through the filter cloth and stored in tanks temporarily.

Customized Palm Kernel Oil Refinery Line & Machine at Low Cost

- Type: cooking oil refining machine

- Production capacity: 80-800kg/h

- Dimension (L*W*H): 710*950 *1560(mm)

- Voltage: 220V/110V, 220v/110v

- Weight: 1070kg

- Main components: Motor, hydraulic system

Palm fruits are received by the palm oil processing equipment in bunches. A hydraulic segmented discharge occurs, and with the use of high temperature, the palm fruits are sterilized. The machine has to be powerful enough to increase the humidity of the palm fruit to the desired level. The machine prevents wasteful decomposition brought about by the breaking down of essential enzymes. The capacity of the palm oil processing plant has to be taken into consideration.

2) Crude oil centrifugal filter: Quickly separate the pressed oil and pomace to obtain cleaner crude oil. 3) Palm kernel special oil pressing machine: Specially designed for palm kernels of different sizes, easy to clean and low maintenance cost. 3. Palm Oil Refining and fractionation equipment

Palm Oil Mill Plant Production Line - Hongde OIL MACHINE

- Raw Material: palm

- Production capacity: 100% vegetable oil machinery

- Power (W): 22kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Weight: 30 tons

processes involved in the extraction and refining of palm oil. It outlines the steps from sterilizing fresh fruit bunches to separating and processing the oil and kernels, and then refining the crude palm oil through degumming, deacidification, bleaching, and deodorization. 2024-09-23

Palm oil mill process includes 6 parts: Palm fruits receiving, sterilizing, threshing, digesting and pressing, crude oil clarifying and palm kernel recovery. SterilizationThe main purpose of sterilization is to destroy the lipase in the pulp, so as to prevent the free fatty acid content in the oil from increasing. We offer both horizontal and vertical […]