6YL-130 Palm Kernel Oil Press Machine

- Type: palm kernel oil press machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Weight:30tons

- Dimension (L*W*H )):48m*12M*15M(30TPD)

- Power (W): Capacity

- Country: lagos

Ⅰ. The 6YL-130 Palm Kernel Oil Press Machine Introduction 1. Screw Oil Press Machine Description. The screw oil press is an oil press that makes full use of the screw driving force to extract oil from the oil to increase the oil output. The structure is simple and the functions are user-friendly. It is suitable for cold pressing and hot pressing.

PALM KERNEL OIL PRESSING MACHINE

- Type: palm oil processing machine

- Production capacity: 100kg/h

- Voltage: 220v

- Main components: Motor

- Weight: 1.5T

- Dimension (L*W*H): 1000* 1000*1250mm

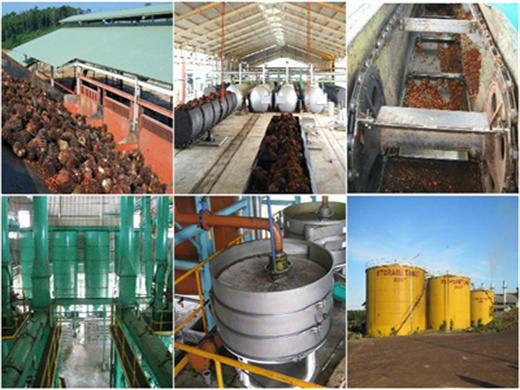

Palm Kernel Oil Pressing Plant Flow Chart: Main process in palm kernel press line: Palm kernel Cleaning : It is used for removing the iron impurities, stone, fiber and pthers. These impurities are bad for machines, especial for the palm kernel oil expeller. Palm kernel crushing:because the palm kernel is hard and big size, it is required to

Palm kernel oil is an edible plant oil extracted from the palm kernel, a by-product of the palm oil mill plant. Our Palm Kernel Oil Press Machine is designed to meet the needs of modern palm kernel oil production with capacities ranging from 10 TPD to 100 TPD. Engineered with precision and innovation, it delivers high-quality oil extraction

Palm Kernel Oil Expeller for Cold Pressing of Palm Kernel Oil

- Usage: palm oil

- Production capacity: 10-160 kg/h

- Voltage: 220v/380V

- Main components: Motor, PLC

- Weight: 240 KG

- Dimension (L*W*H): 700*800*780mm

Palm Kernel Oil Press Machine Applications. Our palm kernel oil press is suitable for pressing high-oil-content oilseeds such as shelled peanuts, tea seed kernels, sunflower kernels, cottonseed kernels, rapeseed kernels, walnuts, rubber seeds and peeled soybeans at room temperature or at low temperature.

Palm kernel oil press machine, also known as palm kernel oil expeller. This machine is suitable for peanut, palm kernel, sesame, palm, soybean, sunflower, rapeseed, olive etc. It is high efficiency with mature product structure and process, the oil yield can be comparable to the large oil press.

Palm Oil Pressing Machine

- Type: cooking oil extraction machine

- Voltage: 220/110V

- Dimension (L*W*H): 50cmX18cmX30cm

- Keywords2: small oil extraction machine

- Keywords1: Press domestic oil

- Weight: 12KG

4) Palm fruit after digesting enters into screw oil expeller for palm oil pressing. Palm Oil Press Station: Separate palm fruit and kernel, and palm oil press machine can obtain CPO (crude palm oil) and palm kernel oil. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil processing.

After bunch reception, bunch sterilizing, threshing and digesting, the palm fruits are pressed into a screw palm oil press. Mixture of oil and cake will be extracted by use of palm oil press machine. Besides, nuts and fibre or press cake will also be discharged as palm oil pressing residues. Palm Oil Pressing Machine (Oil Extraction)

Palm kernel oil press, small palm oil extraction machine

- Raw Material: palm

- Production capacity: cooking oil extraction machine

- Power (W): cooking oil extraction machine

- Voltage: 380V/three phase

- Dimension (L*W*H): Depending on the capacity of the cooking oil processing machine

- Weight: Depending on the capacity of the cooking oil processing machine

The Model 6yl-130 palm kernel oil press machine is a reliable and high-capacity machine that is ideal for small farms of 3-15 hectares. It can process supplied materials from outside for individual household or pre-pressing in submerging oil workshops.

Huatai Oil Machinery is leading professional manufacture and supplier of palm oil production line equipment includes palm fruit oil press, palm kernel oil extraction machine, CPO Refinery, and palm oil fractionation plant. Our team offer turnkey production solution for complete palm oil processing project with competitive cost!