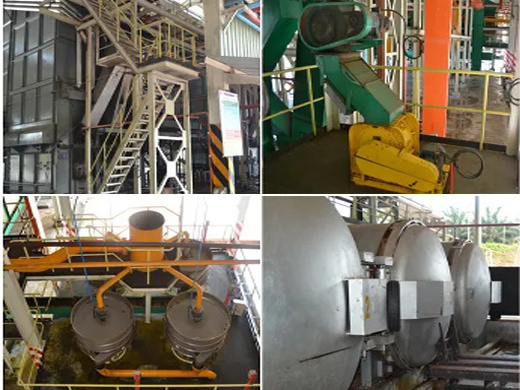

Cottonseed Oil Processing Plant | Extraction Flow

- Type: cottonseed oil processing plant

- Usage/Application: cottonseed

- Finish: ZINC PLATED, Black Oxide, Galvanized, Nickel Plated, Polished

- Measurement System: Metric, Imperial (inches)

- Material: Carbon steel , Stainless steel

- Product Size: M1-M10

- Standard: Self-clinching Nut standard

- Country: cameroon

To improve the oil yield, oil, and cake quality, we use screening and air separation methods to remove impurities in cottonseed. The cotton seeds are first screened to absorb some dust and short lint. Then they are air separated, which can not only remove various impurities in the cotton seeds but also reduce the lint content of the cotton seeds.

HUATAI Provides Turnkey Oil Mill Plant, Oil Pressing Machine

- Type: cottonseed oil processing machine

- Production capacity: 97%-99%

- Voltage: 380v

- Key selling points: Long service life

- Weight: 1600 kg

- Dimension (length*width*height): 2.15 m*1.6 m *2.7 m

An oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining equipment. With a high degree of automation, the oil refining machinery can refine 20 kinds of oil, such as soybean, rape seeds, peanut, etc. in a small production line or in a

The cotton seed cake solvent extracted or pre-pressed cake or full pressed cake or expanded collets. The pre-pressed cake / expanded collets / fully pressed cake from preparatory section is carried by Redler Conveyor and fed to Extractor Either through rotary valve or Plug O Seal to extractor feed hopper incorporated with high and low level

Cottonseed Oil Processing - Oilmillmachinery.net

- Usage: cottonseed oil

- Production capacity: 50~140 ton/day

- Dimension (L*W*H): 16*4.2*6.6 ft

- Main components warranty: Others

- Warranty: One year warranty against manufacturer's defect.

- Weight: 24500 KG

Within the cottonseed oil processing plant, oils extracted from cottonseed must be refined to remove gossypol, a naturally occurring toxin that protects the cotton plant from insect damage. Cottonseed meal is a good source of protein. It is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted.

Improve the Economic Benefits of your Oil Mill Plant: To extract more oil from the cotton seed cake, soybean seed cake etc., ( After extracting, the oil content in cotton seed meal can reach to 1%. ) Normally, after mechanical oil pressing process , the oil content in oil cake is around 8-13%, through our solvent extracting equipment, you can

Cottonseed Oil Extraction Plant

- Type: cooking oil extraction machine

- Production capacity: 98-100%

- Dimension (L*W*H): 1.04*0.95*1.56m

- Voltage: 380 V/220 V

- Weight: 1300 KG

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox, others, others

The products of the cottonseed oil processing plant are cottonseed oil, cottonseed meal, cottonseed hull, and soapstock. Features of Cottonseed Oil Processing Plant. 1. Cottonseed oil mill plant has high automation degree, continuous operation, saving labor. 2. The pre-pressed cake has low residual oil rate and is easy for solvent penetration. 3.

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

50-100 ton cotton oil processing plant screw presser

- Raw Material: cottonseed oil

- Production capacity: 100% oil press machine

- Power (W): 5.5 ~ 18.5 KW

- Voltage: 220V/380V/440V

- Dimension (L*W* H): 1950*1300*1900, according to capacity

- Weight: 950KG

We offer cotton seed oil processing plant for either small scale or big scale according to differnet needs of our customer. The small scale cotton seed oil processing plant involves several processes like entry into the shaker room, where the cotton seeds are cleaned, the cleaned cotton is send through the grin sand where linter’s are removed from the cotton seed. The next step is passing them through hullers, where the tough seed coats are removed.

Cottonseed oil extraction production line solves crude oil extraction from cottonseed cake through processing flows of solvent extracting, mixture oil filtration, wet bran treatment of dephenolizaiton and mechanical desolvent, and low temperature drying, evaporation, gas stripper to obtain crude cottonseed oil.