Groundnut Oil Refining Plant | Peanut Oil Processing Plant

- Type: peanut oil processing plant

- Usage/Application: peanut, groundnut

- Production capacity: 150-200 kg/h

- Voltage: 220 V/380 V

- Main components: Motor, PLC

- Weight: 730 KG

- Dimension (L*W*H): 1675*1000* 1610 mm3

- Country: afghanistan

Apart from its alluring strong aroma and universally liked peanut flavour, the all-purpose cooking oil brings multiple health benefits to the table. By being an active agent in lowering cholesterol and especially the bad cholesterol, it is being accepted gleefully across the globe.

Groundnut Oil Manufacturing Process With Flowchart - Goyum

- Type: peanut oil processing machine

- Voltage: 220V/380V

- Power (W): 22kw

- Certification: ISO,CE,BV

- Weight: 3000KG

- Dimension (L*W*H): 2600*1300*2300mm

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

Peanut oil is light yellow and transparent, bright in color, fragrant in odor, and delicious in taste, and is an edible oil that is relatively easy to digest. Peanut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid). It also contains 19.9% saturated fatty acids such as limonoic acid, stearic

What Are 5 Steps of Edible Oil Solvent Extraction Plant Process

- Usage: peanut oil

- Production capacity: 1-2000TPD

- Voltage: 220V/380V

- Weight: 1000 kg

- Dimension (L*W*H): 1.5*2.6 *3.6 M

- Power (W): 7.5 kw

Our Machinery: Offer You Reliable Cooking Oil Solvent Extraction Plant. Edible oil solvent extraction method is a widely used oil extraction process at present, and is applicable to a variety of raw materials: leaching of soybean oil and rice bran oil, secondary processing of peanut oil cake, rapeseed oil cake, camellia seed oil cake and other

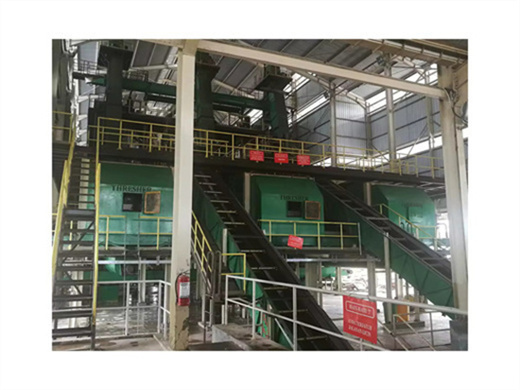

So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing. Big Scale Peanut Oil Plant and Small Scale Peanut Oil Processing Plant. Below are the raw materials for peanut oil, as well as the workshop of KMEC’s peanut oil plant

Peanut oil processing plant - cooking oil making machine

- Type: cooking oil extraction machine

- Production capacity: 5TPD

- Dimension (L*W*H): 2550*1800*2700mm

- Voltage: 380v

- Weight : 1800 KG

- Core Components: motor, pressure vessel, gearbox

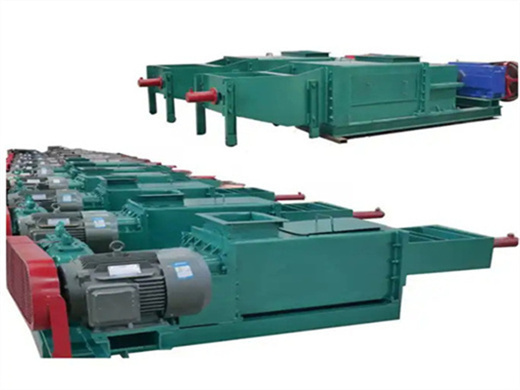

2) Peanut oil solvent extraction workshop: After the pre-treatment, the next step is solvent extraction, which is using the solvent to exact oil from the peanut cakes. By this kind of technology, the residual oil ratio in the oil meal is less than 1%. Peanut oil solvent extraction plant and working process flow chart. 3) Peanut oil refinery

You have two options to obtain the raw materials needed for the vegetable oil extraction plant. You can buy oil seeds from the supplier or have your own farm for the cultivation of oil seeds & nuts. Step 4. Find a good plant location. The location of your business is another very important factor that can make your business more successful.

Peanut Oil Manufacturing Plant Report: Setup & Cost - IMARC Group

- Raw Material: peanut

- Production capacity: 35-50 KG/H

- Power (W): 1.5KW

- Voltage: 380V,220V,110V,440V

- Dimension (L*W*H): 900*850*1550

- Weight: 1000KG

IMARC Group’s report, titled “Peanut Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a peanut oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit

Peanut Oil Pressing Plant is fully adopted mechanical driven, it connects each oil processing machinery together to extract oil with higher oil yield and at the same time, change the single machines by manual into the semi continuous production line to liberate the workforce.