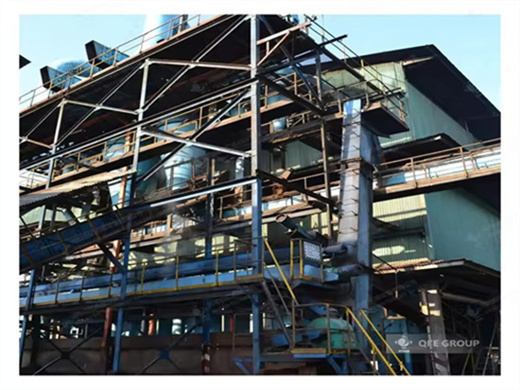

edible oil production in lusaka | Supply of turnkey project

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Production capacity: 500-1000TPD

- Voltage: 380v 440v

- Weight: Depends on the production from canola edible oil refinery

- Dimension (L*W*H): Depends on the production of canola edible oil refinery per day

- Power (W): As production of canola edible oil refinery

- Country: lusaka

we successfully delivered the peanut oil refining production line equipment orders to the customers in China. Groundnut oil processing plant is a specialized enterprise specializing in groundnut oil processing. This time, our customers from Hebei, China purchased a groundnut oil refining production line which is part of the groundnut oil processing plant from us.

Mechanical Methods of Oil Extraction from Peanuts

- Type: peanut oil processing machine

- Weight: 40KG

- Key selling points: multifunctional

- Main components warranty: 1 year

- Outgoing video inspection : provided

- Marketing machinery test report: provided

To commercially extract cold-pressed peanut oil, a twin-screw press is used, and the pressing is performed at specific temperatures that do not exceed 60 °C. The oil yield was not evaluated in this study, but the researchers were very interested in utilizing the by-product of this extraction (i.e., the meal), knowing that 70 kg of PDPM was

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

Various methods for extracting oil from groundnut

- Usage: peanut oil

- Production capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V, 220V/380V/440V

- Application range: Mini competitive oil press machine

- Weight: 870kg

- Dimension (L*W*H): 2100 *1360*1950mm

The only difference is that the groundnut oil press production line need to be worked with groundnut oil solvent extraction plant. Groundnut oil pre-pressing machine can extract most of groundnut oil, the groundnut oil solvent extraction plant can recover almost all the oils and leaves behind only 0.7% to 1% residual oil in the raw material. In

For high oil content oilseeds like cottonseed, rapeseed, peanut, sunflower seeds, etc., before oil solvent extraction, the cooking oil making machine is used to extract 85% to 89% of the oil within the oilseed, and the resulting oil cake is crushed into a certain size, and then for solvent extracting to obtain leached crude oil.

Model Detailed Project Report - uphorticulture.in

- Type: cooking oil extraction machine

- Production capacity: 250-300 KG/H

- Power (W ): 3KW

- Voltage: 380V

- Dimension (L*W*H): 2000x1200x2500mm

- Weight: 2200 kg

kernels for oil extraction.Kernels are stored in the containers and steam is processed at controlled pressure to treat the kernels. In the next step, the kernels are fed into oil expeller. The steam is also fed through the expeller to maintain the temperature for oil extraction. The oil expeller crushes the peanut seeds to extract oil.

Recommended reading: Peanut oil processing plant. Peanut oil pretreatment and pressing machine. Although the peanut pretreatment machine is necessary, the peanut oil press machine is also important. As the core equipment of the peanut oil pressing production line, peanut oil press machine plays a huge role in the whole peanut oil pressing process.

Groundnut Oil Making Process (Peanut), Business Plan

- Raw Material: peanut

- Production capacity: 10 TONS/DAY

- Dimension (L*W*H): 2261MM *686MM*1423MM

- Voltage: 30 hp

- Weight: 4000 KG

- Main components warranty: 5 years

But it still contains several oil-soluble and in oil-soluble impurities. Therefore, it is essential to equip the peanut oil production plant with professional edible oil refinery equipment to get them off and obtain the refined high-quality peanut oil. Groundnut Oil Processing Flowchart. Cost of Groundnut oil extraction machine:

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.