(PDF) Defatting and Defatted Peanuts: A Critical Review on

- Type: peanut oil extraction machine

- Usage/Application: peanut, groundnut

- Production capacity: 75-1250kg/h

- Voltage: 220V/110v

- Main components: pressure vessel, pump, gear

- Weight: 20 KG

- Dimension (L*W*H): 560*350 *180 mm

- Country: ghana

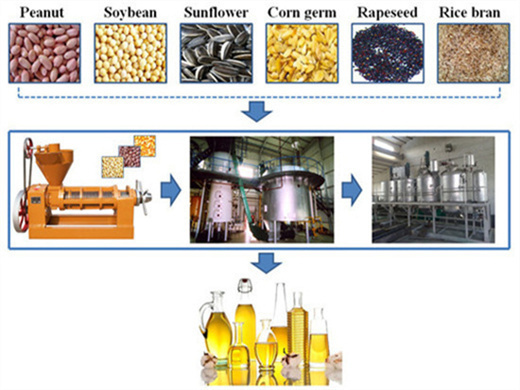

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

Mechanical Methods of Oil Extraction from Peanuts

- Type: peanut oil processing machine

- Production capacity: 80kg/h ~ 600kg/h

- Voltage: match the local voltage

- Weight: According to the capacity of the cooking oil extraction machine

- Dimension (L*W*H): According to the capacity of the extraction machine of cooking oil

- Power (W): according to the capacity of the cooking oil extraction machine

A study carried out in 2019 by Suri et al. examined how peanut oil quality characteristics were affected by a combination of dry air roasting and mechanical extraction using screw pressing . The researchers found that optimal conditions for air roasting were 180 °C for 10 min, followed by cooling at room temperature.

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes. As a result of the first process, a solid matrix is generated

Kinetic and Mass Transfer for the Extraction of Peanut Oil

- Usage: peanut oil

- Production capacity: 6-8t/24h

- Voltage: Customized

- Main components: motor, pressure vessel

- Weight: 1100 KG

- Dimension (L*W*H): 1800*1200*1500MM

solvent to solid ratio and extraction contact time. The optimum condition for the peanut oil extraction was found at 0.6 mm of particle size, 15:1 solid to solvent ratio with an extraction time of 8 hours. Besides, the calculated effective diffusivity is 4.3258 x 10-14 m2/s. The extraction rate constant, k was

FFb oil yield: 22% CPO; FFB oil yield: 2% CPKO: Exporting Countries: ghana; Depending on the variety and other cultivation details, peanuts contain between 45 to 55% oil, with the Spanish variety typically boasting the highest oil content. While many peanut oil mills rely on the traditional double press method, some plants are turning to high

Peanuts Mechanical Methods of Oil Extraction from

- Type: cooking oil extraction machine

- Production capacity: 30 kg per hour

- Voltage: 220 V, 220 V

- Warranty: 1 year, 2 years

- Weight: 120KG, 120kg

- Dimension (L*W*H): 950 *800*1000MM

M e cha nica l M e tho ds o f Oil Ex tra ctio n f ro m P e a nuts | Ency clo pe dia . pub https: / / e ncy clo pe dia . pub/ e ntry / 48924 1/ 14 Mechanical Methods of Oil Extraction from Peanuts Subjects: Engineering, Industrial Contributor: Freddy Mahfoud , Jean Claude Assaf , Rudolph Elias , Espérance Debs , Nicolas Louka

Peanut oil is typically isolated from peanuts using conventional extraction methods, such as mechanical pressing and solvent (n-hexane) extraction [29]. However, many of the peanut proteins are denatured as a result of high temperatures during pressing or due to exposure to the organic solvent.

A novel process for preparing low-fat peanuts: Optimization

- Raw Material: peanut

- Production capacity: 5-500 TPD

- Weight: 500 TONS

- Voltage: 440 V

- Certification: ISO,CE

- After-sales service provided: Engineers available to service machinery abroad.

The defatting ratio is the oil extraction yield, which is the ratio of extracted oil to the total oil that is initially present in peanut seeds before pressing. The mass of extracted oil is the difference between the initial oil content and the residual oil in the cake, which was determined by Soxhlet extraction (as shown in Section 2.6.1 ).

The results showed that the optimum technological conditions for SC-CO2 extraction of peanut oil were as follows: extraction temperature 50 C, extraction pressure 30 MPa and dynamic extraction 120 min. Under these conditions, the oil yield can reach 49%.