What are the common extraction methods of extracting peanut

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Production capacity: 10T/24 hours

- Voltage: 380V

- Main components: Engine oil

- Weight: 1500 KG

- Dimension (L*W*H): 40ft container

- Country: botswana

Recommended reading: Peanut oil processing plant. Peanut oil pretreatment and pressing machine. Although the peanut pretreatment machine is necessary, the peanut oil press machine is also important. As the core equipment of the peanut oil pressing production line, peanut oil press machine plays a huge role in the whole peanut oil pressing process.

Groundnut Oil Manufacturing Process With Flowchart - Goyum

- Type: peanut oil processing machine

- Production capacity: 8-9kg/time

- Voltage: 220v/380v

- Main components: Motor

- Weight: 880 KG, 880 kg

- Dimension (L*W*H): 900*850* 1150 mm

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

Small-scale peanut oil plant (1-10 TPD): Simple mechanical pressing machines and basic refining units. Medium-scale peanut oil plant (10-50 TPD): More advanced pressing equipment, potentially combined with solvent extraction and semi-automated refining systems.

Peanut Oil Processing Plant Manufacturer - Oil Mill Plant

- Usage: peanut oil

- Production capacity: 5TPD

- Voltage: 2200W

- Oil type: Cooking oil

- Weight : 60 KG<br /Main components: Pump

- Dimension (L*W*H): 77*50*81cm

So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing. Big Scale Peanut Oil Plant and Small Scale Peanut Oil Processing Plant. Below are the raw materials for peanut oil, as well as the workshop of KMEC’s peanut oil plant

Groundnuts solvent extraction process. Generally, the Groundnut or peanut solvent extraction is a procedure which involves extracting oil from oil-bearing materials by treating it with a low boiler solvent as opposed to extracting the oils by mechanical pressing methods that are expellers, hydraulic presses, etc.

Peanut oil processing plant - cooking oil making machine

- Type: cooking oil extraction machine

- Production capacity: 1.4-2T/Day

- Dimension (L*W*H): 1200*400*900mm

- Voltage: 220V/380V

- Weight: 320 KG

- Main components: Motor

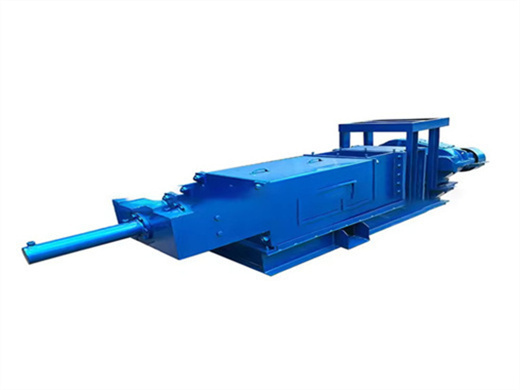

2) Peanut oil solvent extraction workshop: After the pre-treatment, the next step is solvent extraction, which is using the solvent to exact oil from the peanut cakes. By this kind of technology, the residual oil ratio in the oil meal is less than 1%. Peanut oil solvent extraction plant and working process flow chart. 3) Peanut oil refinery plant:

Today, the peanut oil extraction engineer from Henan Huatai Oil Machinery will introduce the peanut oil extraction process in detail. Peanuts have an oil content of over 40%, making them a high-oil crop. The flavor of peanut oil is very popular, so most oil factories use the pressing process to produce peanut oil. The subsequent processes can

What’s The Peanut Oil Extraction Process? - BTMA

- Raw Material: peanut

- Voltage: 220 V/110 V/50-60 Hz

- Weight: 8 KG

- Dimension (L*W*H): 49*25*45 cm

- Main components warranty: 6 months

- Main components: Roller

As it has a high smoke point. For example, peanut oil is often used to fry turkeys. If you have extra peanuts at home. You may wish to extract your own peanut oil.Peanut Oil Extraction. Speaking of peanut oil extraction plant and machinery. It is a complex oil processing procedure in which plenty of manufacturing equipments and processing

The solvent extraction method recovers almost all the oils and leaves behind only 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant etc. In the case of mechanical pressing the residual oil left in the oil cake may be anywhere from 6% to 14%.