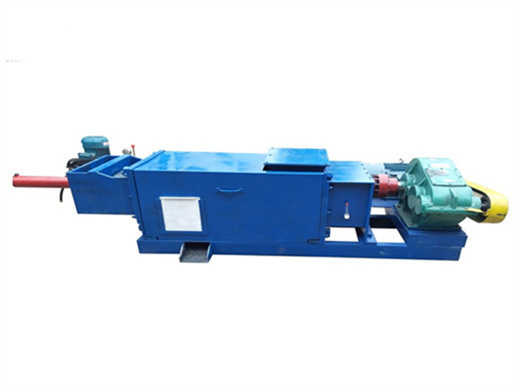

Peanut/Groundnuts Oil Processing | Hot & Cold Press

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Production capacity: 90-99%

- Voltage: 220v/380v

- Warranty: 2 years

- Weight: 350kg

- Dimension (L*W*H): 1920*550*765mm

- Country: uganda

Peanut Oil Processing. Peanut oil is an edible oil extracted from peanuts (also known as groundnuts or ground beans). Peanut oil is usually extracted by two methods: pressing and extraction (Read more: solvent extraction of groundnut oil >>). Among them, the main process steps include cleaning, shelling, drying, pressing, and refining.

Peanut Oil Processing Plant Manufacturer - Oil Mill Plant

- Type: peanut oil refinery machine

- Production capacity: 60%

- Voltage: 220V/380v/customized

- Main components: motor, PLC, others

- Weight: 260 KG

- Dimension (L*W*H): 800*1200*1300mm

Then the cleaned peanut seeds are sent to the oil milling plant to be pressed into oil by oil presses. However, the crude peanut oil usually contains a number of impurities. So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing.

The pressed cake can be crushed and sent to a extraction plant for secondary extraction, extraction oil is refined and sold as ordinary oil. Peanut oil refining plant. The main steps of peanut oil refining. Refining is to remove impurities, odors and pigments from peanut oil and improve the quality and taste of the oil. The refining process

Peanut Oil Production Line,Peanut Oil Pressing Plant

- Usage: peanut oil

- Production capacity: 5TPD-100TPD

- Voltage: 220V/380V/440V

- Delivery time: 10 days after deposit

- Dimension (L*W*H): 1200*400*900mm3

- Power (W) : According to capacity

Peanut oil (groundnut oil), as a kind of light yellow transparent edible oil with a pleasant fragrance and good taste, is relatively easy to digest. Peanut oil contains more than 80% unsaturated fatty acids (including 41.2% oleic acid and 37.6% linoleic acid).

3.Peanut Oil Continuous refining workshop Introduction. Main Processes Introduction: 1) Hydration Deguming & Alkali Refining Deacidification Process. 2) Continuous Decoloring Process Features. 3) Continuous Refining Deodorizing Process. 4) AutomaticControl System

lesotho peanut oil press machine 2000 tpd edible oil

- Type: cooking oil refining machine

- Production capacity: 2.5-3,500 kg/h

- Dimension (L *W*H): 45*30* 19CM

- Voltage: 200-240V

- Weight: 10.5 KG

- Main components: Motor

A Small edible oil production line is designed for small to medium-scale edible oil mill plants, with capacities ranging from 1 TPD to 50 TPD, providing an efficient, cost-effective solution for producing high-quality edible oils from various oilseeds like sunflower, peanut, peanut, canola, rapeseed, Peanut, and more.

Potential use of peanut by-products in food processing: a. Most peanuts grown in the world are used for oil production, peanut butter, confections, roasted peanuts and snack products, extenders in meat product formulations, soups and desserts (Rustom et al. 1996).

The Definitive Guide to Peanut Oil Refining Process

- Raw Material: peanut

- Production capacity: 45 sets per year

- Power (W): 30KW

- Voltage: 380V/440V

- Dimension (L*W*H): 1200*2800*1200mm

- Weight: 500TON

The peanut oil refining process is to transform crude peanut oil into a high-quality edible oil. Include degumming, deacidification, decolorization, and deodorization. info15@cnoilmachine.com 0086-159-3728-9608 0086-159-3728-9608

The flavor of peanut oil is very popular, so most oil factories use the pressing process to produce peanut oil. The subsequent processes can turn it into fragrant peanut oil or pressed peanut oil. The production of peanut oil in oil factories involves multiple steps from raw materials to oil, including cleaning, de-stoning, crushing, softening