Mechanical Methods of Oil Extraction from Peanuts

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Voltage: 230-380-430

- Power (W): 40kw/h

- Certification: CE and ISO9001

- Weight: 30 tons

- Dimension (L*W*H): 20m*16m*15m

- Country: lusaka

Peanuts, being crucial crops of global importance, have gained widespread recognition for their versatility and nutritional value. In addition to direct consumption, either with or without treatment, peanuts can be the subject of diverse applications focusing mainly on two distinct objectives: oil extraction and defatting processes.

Various methods for extracting oil from groundnut

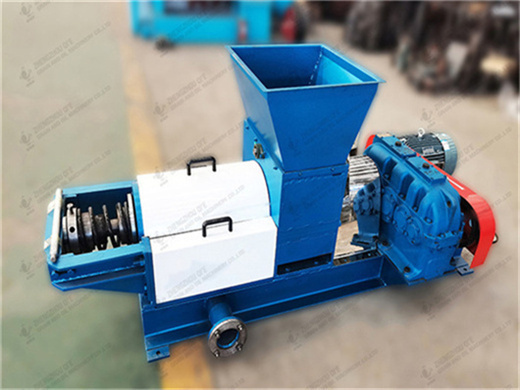

- Type: peanut oil processing machine

- Production capacity: 10-1000MT

- Voltage: 220V/380V/440V

- Weight: 0.5-10T

- Dimension (L*W*H): 1.5* 2.6*3.6 M

- Power (W) : 11KW

The only difference is that the groundnut oil press production line need to be worked with groundnut oil solvent extraction plant. Groundnut oil pre-pressing machine can extract most of groundnut oil, the groundnut oil solvent extraction plant can recover almost all the oils and leaves behind only 0.7% to 1% residual oil in the raw material. In

The solvent extraction process recovers almost all the oils and leaves behind 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant, etc. In the case of mechanical pressing, the residual oil left in the oil cake can be anywhere from 6% to 14%.

Groundnut Oil Manufacturing Process With Flowchart - Goyum

- Usage: peanut oil

- Production capacity: 10T-3000T/D

- Voltage: 220V/380V/440V

- Weight: According to the cooking oil processing capacity

- Dimension (L*W*H): 1200*400*900mm3

- Power ( W): 10-50kw

Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining.

The solvent extraction of peanut oil is a process of extracting peanut oil with n-hexane as extraction solvent. The process consists of four systems: solvent extraction system, wet meal desolventizing system, mixed oil evaporation system, and solvent condensation recovery system. Here I will introduce how these systems works.

What are the common extraction methods of extracting peanut

- Type: cooking oil extraction machine

- Production capacity: 1TPD-1000TPD

- Power (W) : According to capacity

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 1610x615x1260mm

- Weight: 1050 KG

But because of the peanut oil solvent extraction plant 's processing capacity is large and the price is expensive, this extraction method is not suitable for household and small scale cooking oil production business. Peanut oil solvent extraction plant. As a professional manufacturer of peanut oil processing machine, Henan Glory Company can

The mixed oil produced from leaching comprises volatile solvent, nonvolatile oil dissolved therein, and 0.4–1.0% solid meal powder. The purpose of the procedures is to separate the solvent from the mixed oil and remove the solid meal powder to obtain relatively pure crude oil.

(PDF) Defatting and Defatted Peanuts: A Critical Review on

- Raw Material: peanut

- Voltage: 380 V

- Weight: 10000 KG

- Dimension (L*W*H): 3705x1040x2800mm

- Main components: Box changes

- Oil type: Cooking oil, Tung seed, decoctions, Sunflower

This review elucidates the methods used for extracting peanut oil, including mechanical and chemical processes that have been combined with biological or physical pre-treatment techniques.

The solvent extraction method recovers almost all the oils and leaves behind only 0.5% to 0.7% residual oil in the raw material, such as peanuts solvent extraction plant or ground nuts solvent extraction plant etc. In the case of mechanical pressing the residual oil left in the oil cake may be anywhere from 6% to 14%. Peanuts / Groundnuts are