Groundnut Oil Manufacturing Machine

- Type: peanut oil plant

- Usage/Application: peanut, groundnut

- Voltage: 220v/380v

- Dimension (L*W*H): 1200*780*1100

- Oil type: cooking oil

- Main components: gear, others, bearings

- Weight: 140 KG

- Country: nairobi

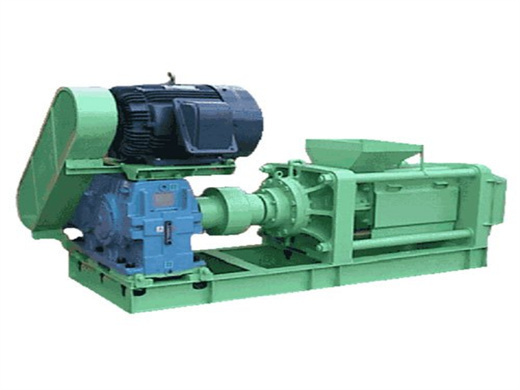

Step 4: Pressing. The peanuts are transfer by conveyor and fed through the hopper of screw press machine. Continuous transport of material by the screw shaft causes pressure to increase to a level needed, which increases friction inside the screw press and generates heat which lowers viscosity of the oil in the crushed seeds thereby increasing the oil flow rate.

Peanut Oil Processing Plant Manufacturer - Oil Mill Plant

- Type: peanut oil processing machine

- Production capacity: 10TPD

- Voltage: 380V

- Raw material: Vegetable seeds, sunflower, etc.

- Oil type: cooking oil<br /Material: Stainless steel

- Main components: others, gears

Then the cleaned peanut seeds are sent to the oil milling plant to be pressed into oil by oil presses. However, the crude peanut oil usually contains a number of impurities. So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing.

Our Company is a manufacture, supplier and exporter of Oil Expeller machine which is specially designed to be used for Edible oil plant. This machines can extract oil from the most of seeds/nuts. Moreover it can crush ground nut, linseeds, mustard seeds, palm kernels, seeds, castor, neem, sun flower seeds etc.

5 Steps for Solvent Extraction Plant Process of Edible Oil

- Usage: peanut oil

- Production capacity: 10-12T/24H

- Voltage: 220v/380v

- Weight: 1700kg

- Dimension (L*W* H): 2350*840*1850mm

- Power: 15kw

For high oil content oilseeds like cottonseed, rapeseed, peanut, sunflower seeds, etc., before oil solvent extraction, the cooking oil making machine is used to extract 85% to 89% of the oil within the oilseed, and the resulting oil cake is crushed into a certain size, and then for solvent extracting to obtain leached crude oil.

Before crushing these oil-rich seeds, they require specific pretreatment steps. The first two steps—cleaning and shelling—happen before the peanuts arrive at the oil mill. Inside the peanut oil extraction plant, roller mills crack the peanut kernels into smaller pieces to increase the surface area for conditioning and pressing. This also

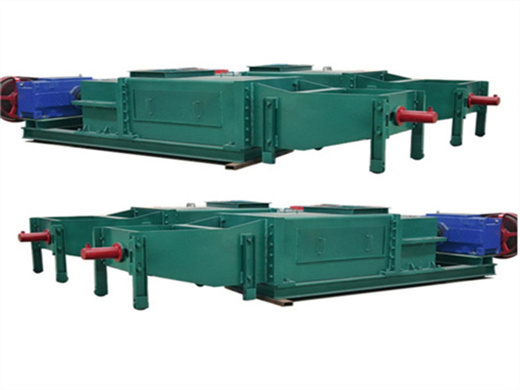

Model Detailed Project Report - uphorticulture.in

- Type: cooking oil extraction machine

- Production capacity: 500-1000TPD

- Voltage: 380v 440v

- Weight: Depends on the cooking oil extruder machine production

- Dimension (L*W*H): Depends on the production of cooking oil extruder machine per day

- Power (W): As output of cooking oil extruder machine

Peanut oil is an edible vegetable oil that is derived from peanuts. The peanut oil market size has the potential to grow by USD 1.90 billion during 2020-2024, and the market’s growth momentum will accelerate during the forecast period. Peanut or groundnut oil is a well-established product with a historically high

The solvent extraction technology is a widely used technique in cooking oil processing process. It is a chemical procedure for extracting oil from the oilseeds material and press cake using a solvent, and usually, Hexane is preferred. The workflow of peanut oil solvent extraction plant including extracting, desolventizing, evaporating

8 Steps To Start a Small Edible Oil Manufacturing Business

- Raw Material: peanut

- Production capacity: 5TPD-100TPD

- Dimension (L*W*H): 3750*850*1990MM

- Voltage: 220V/380V

- Weight: 1800 KG

- Warranty: 1 year, 12 months

You have two options to obtain the raw materials needed for the vegetable oil extraction plant. You can buy oil seeds from the supplier or have your own farm for the cultivation of oil seeds & nuts. Step 4. Find a good plant location. The location of your business is another very important factor that can make your business more successful.

extraction o f essential oil from caraway seeds, in Conf. Rec. 2003 App lication of Power Ultrasound in Ph ysical and Chemic al Processing, Becanson, lagos, pp. 349-