Oils Fats Refining Equipment and Turnkey Plants

- Type: peanut oil refinery machine

- Usage/Application: peanut, groundnut

- Production capacity: 100TPD

- Voltage: 380V

- Main components warranty: 5 years

- Weight: 60000 KG

- Dimension (L*W*H): according to capacity

- Country: nigeria

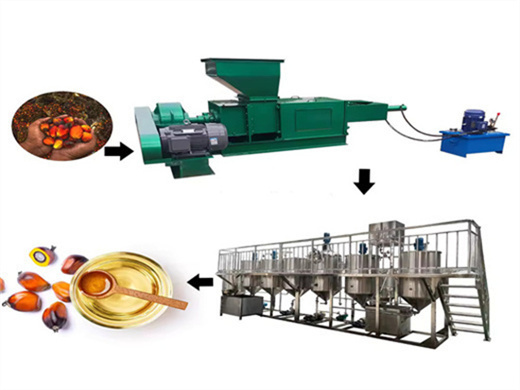

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

What is the process flow of peanut oil refined?

- Type: peanut oil refinery machine

- Production capacity: 10-5000 tons

- Voltage: 380 V 440 V

- Weight: According to the oil presses for cooking production

- Dimension (L*W*H): Depends on the oil presses for cooking capacity

- Power (W ): As oil presses for cooking production every day

1. The 1000kg/d oil refinery machine heating power is 27kw, voltage is 380V, and it can refine all kinds of crude oil by screw oil press extracted. 2. It is made of food grade stainless steel and polished.

It is widely suitable for small type refining mill,specially for the soy oil refinery. In this process, the crude veg. oil filtered is added into the acid and NaOH for neutralization and degumming to separate FFA's, phospolipids and other impurities. Main Steps of Edible Oil Refining 1.

Oil Refinery - Edible Oil Refinery Technology and Equipment

- Usage: peanut oil

- Production capacity: 1T~10TPD

- Voltage: 220V/380V

- Weight: according to capacity

- Dimension (L*W*H): 5432*2636*2345

- Power (W) : according to capacity

Features: For specific kind and grade of crude oil , the degumming and neutralization process can be flexibly adjusted to improve product yield. Physical refining process is suitable for refining of high acid value oil. Efficient system of heat exchanging can reduce the consumption of steam significantly.

DOING Holdings - Henan Glory Oils & Fats Engineering Co., Ltd is a professional vegetable oil extraction machine manufacturer, who can provide 10-1000TPD cooking oil processing plant, solvent extraction plant, and oil refinery plant turn-key project service.

Small Edible Oil Refinery Plant

- Type: cooking oil refining machine

- Production capacity: 15~250KG/h

- Dimension (L*W*H): 650*570 *1125mm

- Voltage: 220v/50hz, 220v/50hz

- Weight: 68 KG

- Main components: Motor

Our Machinery developed a new kind of 1~30TPD small edible oil refinery machine set (capacity 1~30 ton per day).It can process various kinds of crude oil, including all kinds of vegetable oil, seeds oil and palm oil.

Next, I will introduce the refining process of peanut oil in the order of the work sections. Crude peanut oil refining machine. Step1. Degumming. In this step, we add hot water to dissolve colloidal impurities in crude peanut oil to remove excess phospholipids and make the color more vivid and obtain purer peanut oil; Step2. Deacidification

Oil Refinery Plant|Customized Edible Oil Refining Process

- Raw Material: peanut

- Rhythm: Flow production line

- After-sales service: Guided installation

- Production scope: Product line

- Product Capacity: 10tpd-300tpd

- Used oil Cons. Per 1t of Biodiesel Produced: 1025kg

So called “refinery”, generally refers to deacidificationprocess. But in the broad sense, oil refinery process includes crude oil pretreatment, degumming, deacidifying, decoloring, deodorization, degreasing, and dewaxing process, etc. We will design the refining process depending on the quality requirements of refined oil.

Groundnut/ Peanut oil refinery plant. Peanut oil refining process detailed description: (1)Pump crude peanut oil into refining tank and heat with conduction oil, and the temperature will reach about 70 C-80 C after one hour. Add acid or alkali to separate according to the acid value.