Palm Oil Fractionation

- Type: palm oil plant

- Usage/Application: palm fruit, palm kernel

- Plate type: Dye sublimation printing

- Color and page: Multicolor

- Weight: 432.5 kg

- Dimensions (L* W) *H): 1.85*0.66*1.25 m

- Voltage: Single-phase 220 V

- Country: nairobi

Palm oil fractionation plant has three fractions: stearin (palm stearine), soft fat (palm olein) and middle section (palm mid-fraction). After palm oil fractionation, palm oil will be clean after 5.5 hours in 0℃ to ensure it can keep flow ability and transparency in the refrigerator and improve the quality and appearance of palm oil.

Edible oil refinery plant and edible oil refining process

- Type: palm oil processing machine

- Voltage: 220V/380V

- Power (W): depends on the mode of cooking oil production line

- Certification: ISO9001

- Weight: depends on the mode of the cooking oil production line

- Dimension (L*W*H ): depends on the mode of the cooking oil production line

However, fractionation is a process of edible oil modification, which involves the change of edible oil composition. Palm oil and palm kernel oil require fractionation process to get olein and stearin. Plam oil fractionation process. 1. Break the crystals: Pre-heat to break the crystals in palm oil, whose purpose is to make crystallization more

We can provide the palm oil refinery plant from 1 ton to 1000 tons. In general, batch type palm oil refinery plant is with capacity 1-20TPD; The semi-automatic palm oil refinery plant is suggested with capacity from 20-50TPD; And continuous palm oil refinery plant is used for capacity above 50TPD. Of course, this is just an option, not

How to separate crude palm oil into palm olein and palm stearin?

- Usage: palm oil

- Production capacity: 20~2000T/D

- Voltage: 380v/50Hz

- Weight: up to specification

- Dimension (L*W*H): 1360*950*1170mm

- Power (W) : up to specification

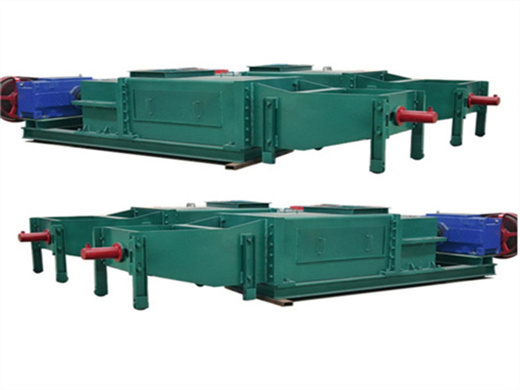

Due to different geographical locations, different countries have different temperature requirements for palm oil fractionation. There are three common palm oil fractionation temperatures: 18°C, 24°C and 36°C, which mainly need the following equipment. Palm oil fractionation plant. 1. One heating tank, two cooling crystallization tanks.

Henan Hongde palm oil fractionation plant adopts advanced crystallization equipment, filtration equipment, and accurate temperature auto-control software to separate palm olein and palm stearin which can get different melting-point fractionation products, including 18℃, 24℃, 32℃, etc.

20TPD palm oil fractionation machine plant equipment list

- Type: cooking oil extraction machine

- Production capacity: 400~600 kg/h

- Power (W): 18.5 kw

- Voltage: 220V/380V

- Dimension (L*W*H): 1500*1600*2500mm

- Weight: 2000kg

Tel: +86-027-8790 7188 Cell Phone: +86 15623270960 Skype: jacky.jkx E-mail: support@palmoilmillmachine.com

20TPD Crude Palm Oil Refinery and Fractionation Plant The client set up this 20TPD physical oil refinery plant and fractionation plant to make palm kernel oil deep processing to get liquid oil and different melting point stearin introduction. The equipment cost of this palm oil refinery plant is around $500,000.

Palm Oil Physical Refining Plant - Hongde Group

- Raw Material: palm

- Production capacity: according to capacity

- Power (W): according to capacity

- Voltage: 110V, 220V, 380V, 440V

- Dimension (L*W*H): 1610x615x1260mm

- Weight: 1050 KG

The physical refining of palm consisting of the following steps: 1.Degumming Degumming process aims to removing the gum impurities in the crude oil to make it suitable for further refinery process, hydration degumming and special acid degumming are the two main methods. 2.Bleaching Bleaching process is mainly used to remove the color through adding white […]

Palm oil fractionation is a kind of new oil processing technology. - By using palm oil fractionation, the palm oil products of different melting points can be obtained, such as 8, 10, 14, 18, 24, 33, 44, 55 degree etc.