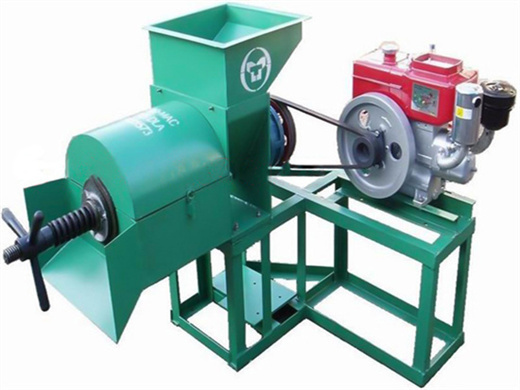

establishing peanut oil processing mill in johannesburg

- Type: peanut oil processing plant

- Usage/Application: peanut, groundnut

- Packing size: 218*107*142 cm

- NW: 775 kg

- Raw material: Vegetable seed

- Capacity: 210-300 kg/H; 50-700 T/24 hours

- GW: 8250 KG

- Country: johannesburg

Seed Oil from Ten johannesburgn Peanut Landraces for Edible - J-Stage. world peanut production in the 2011-2012 was 35,367,000 (groundnut; Arachis hypogaea L.) landraces was established, covering a 2.1 Plant material.

Groundnut Oil Refining Plant | Peanut Oil Processing Plant

- Type: peanut oil processing machine

- Production capacity: 1-2000TPH

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

- Power ( W): 18.5 KW

Apart from its alluring strong aroma and universally liked peanut flavour, the all-purpose cooking oil brings multiple health benefits to the table. By being an active agent in lowering cholesterol and especially the bad cholesterol, it is being accepted gleefully across the globe.

IMARC Group’s report, titled “Peanut Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a peanut oil manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit

Oils Fats Refining Equipment and Turnkey Plants - Myande Group

- Usage: peanut oil

- Production capacity: 100-200 kg/h

- Voltage: 380 V

- Weight: 900kg

- Dimension (L*W*H): 1400*600*600mm

- Power: 5.5 kW

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

Above is the main peanut oil extraction methods that are widely used in commercial vegetable oil processing plant to improve the oil production efficiency and oil quality. Before starting the peanut oil extraction process, the peanut/groundnut should be pretreated to ensure high oil output.

Batch Type Small Edible Oil Refining Plant - Oil mill

- Type: cooking oil extraction machine

- Production capacity: 20-2000T/day

- Power ( W): 11KW

- Voltage:220V/380V/440V

- Dimension (L*W*H): 1.5*2.6*3.6M

- Weight:0.5-10T

The Batch-type edible oil refining equipment is designed to handle various types of crude oils, including palm oil, soybean oil, sunflower oil, peanut oil, and more. It performs several refining processes in a batch mode, allowing for flexibility and control over the refining process.

The Chinese peanut oil mystery • A maximum oil yield is 42%, in other words, 1 ton of oil requires at least 2.38 tons of peanut kernels • Chinese importers pay 850 US$ / Ton CIF for oil grade peanuts. This means their production cost are 2.38x$850= $2023 for peanuts alone. • Yet 1 ton crude oil sells for around $1250 since 2014…

9.10.2.2 Peanut Processing - U.S. Environmental Protection Agency

- Raw Material: peanut

- Weight: 480 KG

- Volume of oil extraction tank: 0.1 m3

- Main components: Engine

- Vacuum of the evaporation chamber: 0~-0.08 MPa

- Cooling water consumption: 3 t/h

peanuts further and causes them to turn brown as peanut oil stains the peanut cell walls. Following roasting, peanuts are prepared for packaging or for further processing into candies or peanut butter. Typical peanut roasting processes are shown in Figure 9.10-2.2-3. There are 2 primary methods for roasting peanuts, dry roasting and oil roasting.

So for edible oil, the pressed peanut oil needs to be extracted in the oil extraction plant before the extracted oils are sent to the oil refining plant for further processing. Big Scale Peanut Oil Plant and Small Scale Peanut Oil Processing Plant. Below are the raw materials for peanut oil, as well as the workshop of KMEC’s peanut oil plant