Peanut Oil Expelling Equipment and Factory Insights for

- Type: peanut oil equipment

- Usage/Application: peanut, groundnut

- Production capacity: 1-30 tons/day

- Voltage: 380V-440v

- Weight: according to process capacity

- Dimension (L*W*H): could be adjusted

- Power (W): according to process capacity

- Country: tanzania

The Process of Peanut Oil Expelling. The operation of peanut oil expeller factories involves several key steps to ensure quality oil production. The process begins with the careful selection and cleaning of raw peanuts. Ensuring that the peanuts are free from contaminants is critical to producing high-quality oil. peanut oil expeller factories

Peanut oil expelling equipment - Eureka | Patsnap

- Type: peanut oil processing machine

- Production capacity: 140-280 kg/h

- Voltage: 380 V

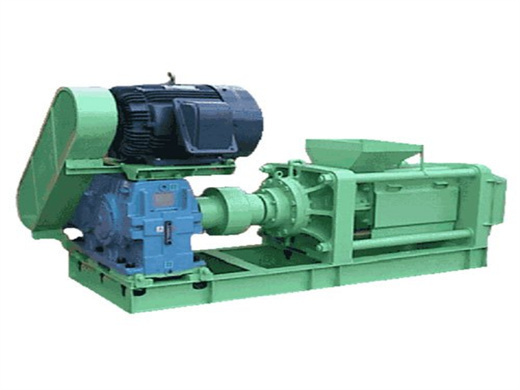

- Main components: as the picture shows

- Weight: 220 KG

- Dimension (L*W*H): 1800 *1300*1680mm

A kind of technology of oil pressing equipment and peanuts, which is applied in the direction of fat production, fat oil/fat production, presses, etc. It can solve the problems that the oil residue cannot be filtered to clean the oil stains in the pressing barrel, and achieve the effect of improving oil extraction efficiency and easy cleaning

mustard oil expeller machine price/groundnut oil machine; oil extractor machine at rs 80000/unit oil processing machinery; seed oil expelling machine suppliers all quality seed oil

Peanut Oil Making Machines for Sale|Best Manufacturer

- Usage: peanut oil

- Customized: Customized

- Product Capacity: 1tph-100tph

- Engineer design: Yes

- Materials: Carbon steel and steel. Stainless steel

- Oil rate: Cake Residual press: ≤ 6%

The oil content of peanut is approximately 42% to 52% oil. Peanut oil is mainly used for cooking purpose as it contains lots of protein and 80% unsaturated fatty acids like oleic acids and linoleic acids. Peanut oil is in light yellow transparent color and has a fragrant smell, and their taste is very delicious. Groundnut / Peanut Oil Making

The introduction of hydraulic peanut oil press machine Hydraulic peanut oil press machine to produce pure and assured edible oil. The whole cooking oil expelling process is visible and needs only about 5-7 minutes; Peanut oil expeller is quite suitable to individual households and small oil mills in the countryside due to its little room occupancy and high pressing speed.

Design and Development of A Groundnut Oil Expelling - Scribd

- Type: cooking oil extraction machine

- Product type: Nut and seed oil

- Cultivation type: Organic

- Processing type: Refined

- Packaging: Bottle glass, bulk, tin (canned), drum, gift packaging, glass jar, plastic bottle, vacuum packaging, according to customer demand

- Purity (%): 100

The document describes the design and development of a groundnut (peanut) oil expelling machine. Key components include a speed reduction gear, expellant unit with screw shaft, drain collector, and driving/driven pulleys. Groundnut seeds are roasted before being fed into the machine. The machine was tested and performed best at 60 revolutions per minute. Preliminary tests showed heating of the

Key Features: Compatible with 30+ Oil Crops: Works with peanuts, sesame, sunflower seeds, palm fruit, olives, and more. Efficient Spiral Squeezing: Maximizes oil yield while ensuring smooth operation. Low-Temperature Pressing: Retains protein content in pressed cakes. Vacuum Filtration: Delivers pure, residue-free oil.

Peanuts Oil Maker Machine - Advance Oil Press Machine

- Raw Material: peanut

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 48m*12M*15M(30TPD)

- Power (W): 22kw

- Weight: 30 tons

- Certification: ISO CE

9 Bolt Oil Machines 20 HP motor operating capacity 170 to 180 Kg per hour. An oil extraction machine, also called an oil press or expeller, uses high pressure and heat to squeezethe oils out of a plant product.

The pressure breaks down the cellular structure of the peanuts, allowing the peanut oil to be extracted. Next, the peanut oil moves through the vacuum filtering section, where any oil residue is separated and collected on top of the filter cloth. In the end, we obtain clean peanut oil. This outlines the complete process of extracting groundnut oil.