Complete Cotton Seed Oil Processing Plant

- Type: cottonseed oil refinery plant

- Usage/Application: cottonseed

- Production capacity: 50 -3000TPD

- Voltage: 380v 440v

- Weight : Depends on the production of the edible oil pressing machine

- Dimension (L*W*H): As edible cooking oil presser machine production per day

- Power (W): As edible cooking oil press machine production per day

- Country: mozambique

The complete cotton processing plant has a series of process, including delintering, dehusking, oil pressing, solvent extraction for oil, oil refining and more. Now, it has been a popular for many investors or oil millers to start or expand their edible oil manufacturing business by setting up cotton seed oil processing plant .

Edible Oil Refinery Plant, Leading Manufacture and exporter

- Type: cottonseed oil refinery machine

- Production capacity: 98--100%

- Voltage: 380v

- Warranty: 1 year

- Weight: 2500 KG

- Dimension (L*W*H): 3200*2600*2950mm

We can supply a Refining Plant ranging upto 500 TPD (Tons per day) to our Clients for any kind of Edible / Non edible Crude Oil. We can generate an optimum solution and provide a complete package customized / based on Client’s requirement.

The mozambiquen Company of the Refining Industries STIR, was created in 1961 following an agreement between the mozambiquen State and the Italian group ENI. Its purpose is the refining of crude oil in order to satisfy the needs of the national market in petroleum products.

cotton seed oil mill project report

- Usage: cottonseed oil

- Automatic grade: Semi-automatic

- Production capacity: 1-500T/D

- Dimension (L*W*H):1910*550*765 mm

- Power (W): 7.5kw

- Voltage: 220V /380V

Cottonseed Oil Refining Plant. Cottonseed mixed oil refining is to degum and deacidify the mixed oil (the mixture of solvent and oil) gained from the first vaporization system in cotton seed extraction technology before it is not totally evaporated and desolventized, and before its viscosity and density are lower than crude oil.

Cottonseed oil is extracted from the seeds of cotton plants. Refined cotton seed oil is edible. India, China, Pakistan, USA and Brazil are among the top producers of cotton seed oil in the world. Let us now know about the various aspects of cottonseed oil plant - it's manufacturing process, world market status and other features.

Cottonseed Oil Refining Plant

- Type: cooking oil refining machine

- Production capacity: 100 kg/h

- Dimension (L*W*H): 1.2*0.78 *1.1 m

- Voltage: 220 V 380 V

- Weight: 300 KG

- Main components: motor, pressure vessel, PLC

If you are planning to set up a cottonseed oil refining plant or oil refinery equipment for other oilseeds, you are in the right place!. We take the opportunity to intoduce Our Machinery, an ISO 9001 Company, a leading oil mill engineering firm, established in 1997, specialist in vegetable oil extraction and refinery field.

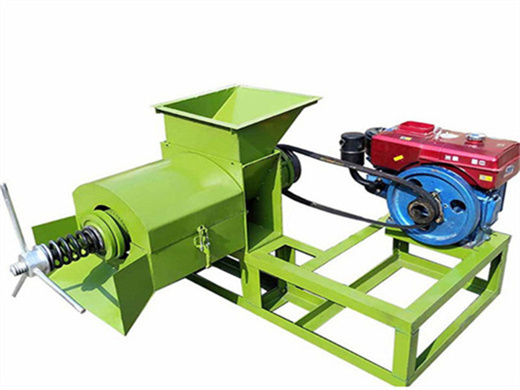

1-50T/D Edible Oil Production Line; Oil Refinery Plant. Large Continuous Edible Oil Refinery Plant 20-5000TPD; Batch-type Edible Oil Refining Equipment 1TPD to 20TPD; 10T/D Edible Oil Refinery Plant; 1-5T/D Edible Oil Refinery Plant; Cotton Seeds Oil Refinery Plants; Seed Oil Press. Integrated Screw Oil Press; Screw Oil Press; Peanut Oil Press

Cotton Seed Processing, Oil Extraction & Refining Plant

- Raw Material: cottonseed oil

- Production capacity: 41000 kg

- Dimension (length x width x height): 2010 x 690 x 1430 mm Weight: 830 kg Main components: pressure vessel, gear, Bearing, Gearbox

- Voltage: 380 V/50 HZ

- Oil Raw material: sesame, sunflower, soybean, palm, coconut

- Advantage: High oil yield

Cottonseed could either be processed by the traditional crude method of crushing seed without Delinting in un-decorticated form or by scientific processing used for Cotton Seed Processing, which involves removal of De-linters, decortication, separation of hull, expelling, solvent extraction and refining of oil. Scientific processing of Cotton

Filed Visit of Rapeseed Oil Production in mozambique - Our Machinery. The professional technical engineers team from Our Machinery went to mozambique in June 2019 with the aim to help our customer solve the technical problems about setting up the complete rapeseed oil production plant, which includes one 20tpd oil pressing line, one 10tpd edible oil refining line and one 10TPD automatic bottle