Cottonseed Oil Expeller Manufacturer, Seed Cleaning Machinery

- Type: cottonseed oil expeller

- Usage/Application: cottonseed

- Production capacity: 150 kg/h

- Voltage: 220 V

- Main components: Motor, Motor

- Weight: 120 KG

- Dimension (L*W*H): 1000*350* 500 mm

- Country: pakistan

Established in 2004, Mitsun Engineering is an exporter and manufacturer of engineering machinery such as Oil Expellers, Cottonseed Oil Expeller, Cotton Seed Expeller, Seed Cleaning Machinery. Our company has the capability to supply various types of machines as per the drawings of the clients and their specific requirements.

Cotton Seed Oil Expeller - Multi Seeds Oil Machine

- Type: cottonseed oil processing machine

- Certification: BV and ISO9001-2000

- Product type: cooking oil fractionation plant

- Voltage: 220v/ 380v/other

- Capacity: 10-1000tpd

- Material: Carbon steel

Cotton Seed Oil Expeller. A Cotton Seed Oil Expeller is a machine designed to extract oil from cotton seeds using mechanical pressure. Operating with mechanical efficiency, it ensures a thorough extraction process without the use of heat or chemicals. The resulting cotton seed oil maintains its natural properties, making it suitable for various

6. Industrial Scale Oil Mill: These are large-scale units capable of processing a high volume of seeds or nuts per day, suitable for commercial operations. 7. Expeller with Seed Cleaning Unit : Includes a seed cleaning section, which removes impurities from the seeds before pressing, ensuring higher oil yield and quality. 8. Automatic Oil

Welcome to Sharma Expeller Company

- Usage: cottonseed oil

- Production capacity: 50-1000 kg/h

- Voltage: 380 V

- Certification: ISO9001,CE,BV

- Weight: 40 tons

- Dimension (L*W*H): According to specification

Established in the year 1988, we, "Sharma Expeller Company" is engaged in manufacturing and exporting Oil Mill Machinery & Material Handling Equipment to our customers. Our products are Oil Expellers, Pilot Scale Oil Expellers, Oil Cleaning Section, Seed Cleaning Machine, Stone Crusher Spare Parts, Industrial Chains, Nuts & Bolts and Bio Diesel

Our oil mills can be tailored to handle various oilseeds, from mustard seeds to Cotton Seed/ Ground Nut Seed/Gingelly Seed, And other various oil seeds. Oil Expeller Plant An oil expeller plant is a facility where oil is extracted from seeds or nuts by mechanical pressing.

Cotton Seed Oil Expeller for Sale|Premium Quality & Low Cost

- Type: cooking oil extraction machine

- Production capacity: 1tpd-30tpd

- Power ( W): 11 KW

- Voltage: Design according to customer demand

- Dimension(L*W*H) : 4935*1523*2664

- Weight: Standard

Cotton seed oil expeller are readily available with various companies assembling machines that are well versed for small oil mill of cotton. The expeller come in different size and shapes even for the small-scale producers with limited spaces. Small oil mill factory encourages self-employment as more jobs are generated.

Oil expeller machine is the soul equipment of the pressing process, it can be divided into small oil press and high capacity oil press according to its capacity. The top features of cotton seed oil expeller machine are based on the traditional product but include a variety of enhancements, implemented after-in-depth research on cotton seed oil

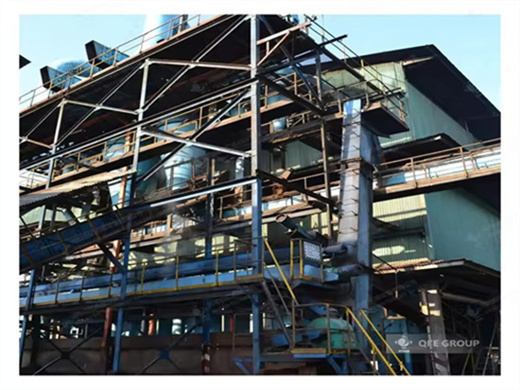

Cottonseed Oil Mill Plant - Oil Expeller

- Raw Material: cottonseed oil

- Production capacity: 50-500kg/h

- Dimension (L*W*H): 900*1000*1400 mm

- Voltage: 220V/380V/as your request

- Weight: 950 KG

- Key selling points: Multifunctional

Application of Cottonseed Oil. The cottonseed oil is cholesterol free and extracted from the seeds of various cotton plants. More than 95% of the cottonseed oil is primarily used as cooking oil. Cottonseed oil is light golden color with light mild taste. It is used primarily in the form of mayonnaise or in addition to salads.

Mitsun Engineering is manufacturing a wide range of cotton seed expeller, oil mill machinery, seed cleaning machinery, solvent extraction plants, Cotton Ginning Machine, Palm Oil Mill, Oil Mill Expellers and allied products. We use furnace, die casting, shot blasting and other processes to fabricate Ginning Machines that are used to produce