Oil Refinery Equipment for Oil Mill Plant

- Type: soybean oil refinery equipment

- Usage/Application: soybean

- Production capacity: 45 kg per hour

- Voltage: 220-240 volts

- Main components warranty: 2 years

- Weight: 67 KG

- Dimension (L*W*H): 840*240*540 mm

- Country: johannesburg

3.Physical refining adopts the new type of continuous deacidification and deodorization.suitable for plant oil with high acid value and low resin content. Actual production proves that the process has the following advantages: good acid removal ability.good thermal decoloration effect.high rate of refining and better oil quality.

Issues That Must Be Considered when Setting Up an Soybean Oil

- Type: soybean oil refinery machine

- Type of product: Fruit oil

- Type of processing: Refined

- Packaging: Bulk

- Type of cultivation: COMMON

- Refined type: Fractionated oil

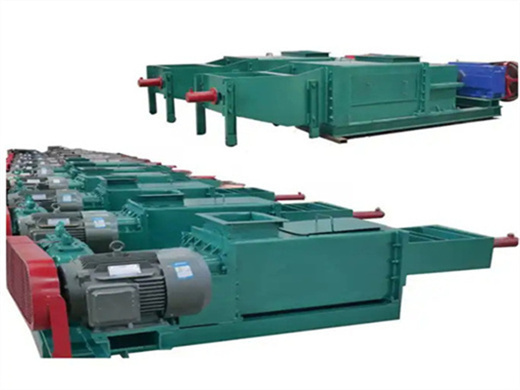

Choosing a set of soybean oil refining equipment that suits you is the key to starting a soybean oil refining plant. The refining equipment that can be selected according to the daily output of soybean oil crude oil are: intermittent, semi-continuous, and full-continuous refining equipment configurations. Soybean Oil Refining Production Line

No. Equipment name Model Q.T.Y(set) Power(KW) Remark 1 Soap stock pot LZJ180 1 5.5 2 Oil refining pot LYY220 1 7.5 5.5/7.5dualspeed motor 3 Washing pot LYY220 1 7.5 5.5/7.5dualspeed motor 4 Decoloring pot TSG220 1 7.5 5 Crude oil tank MYX60 1 0 6 Alkali liquid tank JYX2.0 1 0 7 Alkali deployment tank […]

How to refine crude soybean oil?What machine do I need?

- Usage: soybean oil

- Production capacity: 100 kg/h

- Voltage: 220 V

- Main components warranty: 2 years

- Weight: 695 KG

- Dimension (L*W*H): 1200*400 *900mm

According to the degree of work continuity, the soybean oil refinery machine has three types: batch type soybean oil refinery machine, semi-continuous type soybean oil refinery machine and full-continuous type soybean oil refinery machine. Besides, using different method of deacidification, the soybean oil refinery machine is also different.

Reliable seed oil processing equipment covering all steps of refining for any type of edible seed oil; Oilseed processing solutions for boosting capacity, limiting loss and increasing yield, creating new profitable possibilities; Improved sustainability and reduced operational costs thanks to unique technologies for maximizing energy efficiency

Soybean Oil Refining Machinery - Find Oil Refinery Equipment

- Type: cooking oil refining machine

- Production capacity: 100% oil extraction process

- Power (W): 10-50kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): Depends on its capacity

- Weight: Depends on its capacity

In the soybean oil extraction industry, choosing the right extraction method is crucial for maximizing oil yield and maintaining oil quality. The two primary methods—pressing and solvent extraction—each has difference processes, advantages and considerations. This article aims to clarify these differences, helping clients make informed decisions based on their specific needs.

Refining also ensures that the oil has a longer shelf life, better taste, and improved color and clarity. Soybean oil refinery machines can vary in capacity and complexity, from small batch systems to large, continuous refinery plants, depending on production requirements. Types of Soybean Oil Refinery Machines 1.

Soybean Oil Process Machine

- Raw Material: soybean

- Voltage: 440V

- Dimension (L*W*H): 1200*400*900mm3

- Power(W): 11KW

- Color: According to customer requirements

- Oil content: 25%

4. Filtration Equipment: - Filter presses or continuous filters are used to clean the crude oil before and during the refining process, removing impurities and unwanted particles. 5. Soybean Meal Processing Machines: - After oil extraction, the soybean meal (a by-product) is processed further using machines like toasters and coolers.

At the same time compared with fully continuous oil refinery plant, Semi-continuous oil refinery process needs less investment cost. The semi-continuous oil refinery capacity can be designed according to customer requirement. It’s suitable for the middle type oil refinery plant from 10TPD to 50TPD. So it is also called middle scale oil