Soyabean Oil Refinery Plant

- Type: soybean oil refinery plant

- Usage/Application: soybean

- Production capacity: 150-20000 kg/h

- Voltage: 220 V

- Main components: Motor, Other

- Weight: 120 KG

- Dimensions (length x width x height): 73*81*120 cm

- Country: afghanistan

We are leading manufacturers and exporters of Soyabean Oil Refinery Plant systems for processing the crude soya oil into the refined soya oil. Refining technology means separating impurity from oil in order to enhance stability and purity of oil. Soya oil refining can be utilized in order to ensure procurement of best quality oils at vary less

Soybean Oil Refining Process Unveiled | Expert Guide

- Type: soybean oil refinery machine

- Production Capacity: 1TPD-1000TPD

- Voltage: 380V/50Hz/Three Phase

- Weight: 10Ton-100Ton

- Dimension ( L *W*H): 37*7.5*18.5-87*12*30

- Power(W): 7.5kw

Complete Soybean Oil Production Plant Layout. The refining of soybean oil, a process that removes impurities and enhances its stability, is a crucial step in ensuring the oil's superior quality. With its demand steadily increasing across industries, the market for soybean oil and its refined products is poised for further growth.

Oil Refining. An oil refinery plant is the last step in the cooking oil production line. The purpose of a cooking oil refinery plant is to remove harmful impurities and useless substances from crude oil. Then improving the storage stability of cooking oil and making the oil's smell and color comply with national standards.

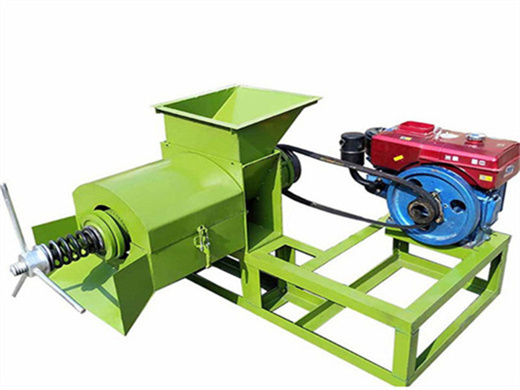

Soybean Oil Processing Plant | cooking oil refinery plant

- Usage: soybean oil

- Production capacity: 5TPD

- Voltage: 220V/110V

- Main components: Motor

- Weight: 11 KG

- Dimension (L*W*H): 42 * 16 *31cm

Advantages Of Jagdish Soybean Oil Refinery Plant Today, Jagdish is leading the edible oil refining industry with its latest techniques and energy efficient plants. We have supplied more than 100 plants in different parts of the world on turnkey basis.

Capacity Range: Our refinery plants range from 2 to 5,000 tons per day (TPD), accommodating various production scales.; Custom Solutions: We provide tailored refining solutions based on the specific characteristics of different crude oils, such as palm oil, soybean oil, sunflower seed oil, peanut oil, rapeseed oil, corn germ oil, cottonseed oil, linseed oil, and rice bran oil.

Soybean Oil Refinery Plant | Refined Soybean Oil

- Type: cooking oil refining machine

- Voltage: 220 V/380 V

- Dimension (L*W*H): 2200*1600*2150mm

- Power (W): 15 KW

- Weight: 1300kg

- Certification: ISO9001

Hongde soybean oil refinery plant ensures less oil loss, high stability, effective FFA removal, and versatile processing. Get a free quote. info15@cnoilmachine.com 0086-159-3728-9608 0086-159-3728-9608

Soybean Oil Extraction Process. Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.

Soybean Oil Refinery Plant - Mectech

- Raw Material: soybean

- Production capacity: 50%-55%

- Dimension (L*W*H): 700*500*1000mm

- Voltage: 220V/380V

- Weight: 580 KG

- Main components warranty: 1.5 years

Being one of the leading soya solvent extraction plant suppliers, we have supplied more than 350 plants in different parts of the world on turnkey basis. We believe in moving with time thus keep up with the technical advancements in edible oil refining industry. Soybean Oil Refining Multiple Advantages:

In the U.S.A. and in Europe, for soybean oil refining, the caustic soybean oil refining process is by far the most used. The physical refining of palm oil, lauric oils and other fats and oils that have a low phosphatide content by dry degumming and bleaching followed by distillation, deodorization, is 20 to 25 years old and common practice today.