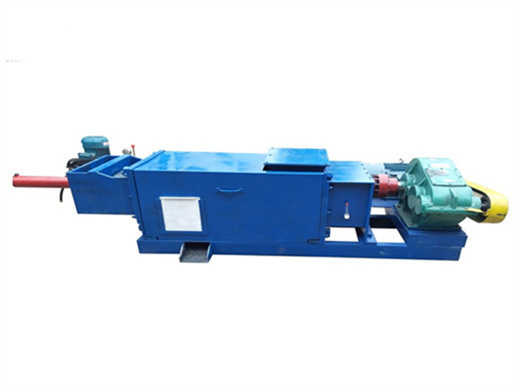

Sunflower Oil Refinery Plant Process - Oil Expeller

- Type: sunflower oil plant

- Usage/Application: sunflower

- Production capacity: 100 kg/h

- Voltage: 380

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox, others

- Weight: 1700 KG

- Dimension (L*W*H): 1400*1300*2550 mm

- Country: indonesia

One of the factors of sunflower oil is its typical properties of wax. Sunflower oil contains wax from 1000 ppm to 1500 ppm based on the variety of seeds. The wax give haziness to the oil after refining. Hence it becomes necessary to remove the wax to avoid haziness of the oil and also stickiness of the Oil.

How to extract sunflower oil from sunflower seeds?_Tech

- Type: sunflower oil processing machine

- Production capacity: 80kg/h

- Voltage: 220V

- color: blue, green, gold, can be customized

- Weight: 130kg

- Dimension (L*W*H): 900*700*1200(mm)

The making process flow chart of sunflower oil refinery plant. The sunflower oil extracted by sunflower oil pressing plant and sunflower oil solvent extraction plant are both crude sunflower oil, in which there are many impurities. If the customer want to get refined sunflower oil, the sunflower oil refinery plant is necessary. Henan Doing

So, if you want to get high quality of sunflower oil, you must to sent crude sunflower oil into sunflower oil refinery plant. 1-5TPD mini sunflower oil refinery plant 3D model picture. In sunflower oil refinery plant, crude sunflower oil is settled, filtrated then through degumming, deacidification, decolorization, deodorization and dewaxing

Sunflower Oil Extraction Process, Methods – A Full Guide

- Usage: sunflower oil

- Production capacity: 98%

- Voltage: 380 V

- Weight: 36ton

- Dimension (L *W*H): 18m*8m*8m

- Power (W): 12-35 KW

Sunflower seeds from the oil-type contain about 20% to 30% hulls that are sometimes removed before oil extraction to ensure the quality of both oil and sunflower meal. De-hulling is completed when the seed has a moisture content of 5% after cleaning.

Prepress solvent extraction relies on exerting medium pressure on the prepared seed to separate the majority of the oil, followed by solvent extraction to separate additional oil from the solids fraction, recovering over 40% oil from the seed in modern crushing plants. In a typical sunflower crushing plant using the prepress solvent extraction

What Are Sunflower Oil Refining Process Techniques?

- Type: cooking oil extraction machine

- Production capacity: High

- Power (W) : Up to capacity

- Voltage: 380 V/220 V

- Dimension (L*W*H): 1360*950*1170 mm

- Weight: Up to specification

(Relaed Article: Sunflower Oil Refinery Plant Cost>>) Flow Chart - Sunflower Oil Refining Process. Pretreatment: The pretreatment stage involves sedimentation and filtration of the raw sunflower seed crude oil to remove large particles and impurities. Degumming Stage: Soluble impurities in crude sunflower oil not only affect stability of the

Cooking Oil: Sunflower oil is known for its premium characteristics such as light colour, bland flavour, rich unsaturated fatty acids, low linoleic acid and high smoke point. From improving heart health and keeping the skin glowing from within to boosting energy and strengthening the immune system, the goodness of sunflower oil can help take

Sunflower oil manufacturing process - Edible Oil Expeller

- Raw Material: sunflower

- Production capacity: 20-500T/D

- Power (W): 100kw

- Voltage: 220V/380V/440V

- Dimension (L*W*H): 900*850*1550mm

- Weight: 1000kg

Third, cooking sunflower seeds are ready for oil pre-press. Fourth, pre-presse sunflower seeds. Here only pre-press part of sunflower oil, oil residue inside cake (about 12-16%) will be extracted in oil extraction process. After pre-pressed, the crude sunflower oil will be delivered directly to sunflower oil refining, and pressed cake to oil

Sunflower seed oil is cold-pressed. The cold-press entails minimal processing to produce a light, flavorful oil suitable for some cooking needs. Sunflower seed oil manufacture involves seeds cleaning, seed de-hulling, seeds grinding, seeds pressing and extracting crude oil, crude oil refining. 1. Cleaning: