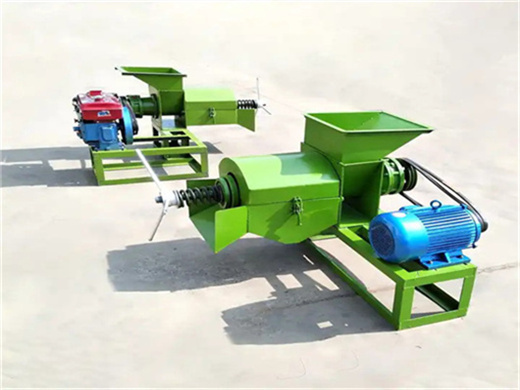

Palm Fruit Oil Pressing Machine

- Type: sunflower oil press machine

- Usage/Application: sunflower

- Production capacity: high

- Voltage: 380V/50HZ

- Main components: motor, gear, bearing, gearbox

- Weight: 268 KG

- Dimension (L*W*H): 1020*720*798mm

- Country: mozambique

This palm fruit oil machine adopts process of sterilization, threshing, digesting, pressing, clarification, purification, drying, depericarper, crushing and final pressing. This mature design fulfills the lowest fuel consumption, steam driving, and self-sufficient energy supplying.

Efficient Sunflower Oil Production Machines

- Type: sunflower oil processing machine

- Production capacity: ≥98%

- Voltage: 380V/50Hz

- Oil Product Company type: Oil presser machine with oil expeller

- Main components: Motor, Gearbox, Frame, Juicer part, Feeding system

- Dimension (L*W*H): 3030*600*1794 mm</li <liWeight: 1700 KG

4. Oil Filtration Machine: - Filters the oil to remove solid particles, impurities, and seed residue. - Produces clear, high-quality sunflower oil suitable for consumption or further processing. 5. Oil Refinery Machine (optional): - Used to refine crude sunflower oil to remove impurities like free fatty acids, phospholipids, and unwanted odors.

Palm oil press machine. 1. Sterilize. As the first step in palm fruit crushing, sterilization is crucial to the quality of palm oil. 2. Threshing. The main function of threshing is to separate the palm fruits from the fruit bunches. The sterilized palm fruit bunches are transported to the drum threshing machine. 3. Pressing process.

Leading Twice Threshing Palm Oil Pressing in mozambique

- Usage: sunflower oil

- Dimension (L*W*H): 55*32*54CM

- Weight: 60kg

- Material: Stainless steel<br /Color: Silver

- Name : Butter crusher machine for cooking

- Voltage: 220v, 220V

Because of cooking, sterilizing, threshing and mashing made the pulp soft and damage pulp cell structure, the palm pulp becomes soft and cell is broken. Then sent it to continuous screw press. After pressing, our machine divide oil palm fruit into two parts, the mixture of oil, water and solid impurities, and the press

With more than 200 patented technologies as the core, Huatai Oil Machinery has overcome the high oil loss and high energy consumption problems in palm oil processing – from fresh fruit (FFB) sterilization and pressing to crude palm oil (CPO) refining and fractionation, the oil output rate of our palm oil equipment leads the industry by 5%-10%

Palm Oil Processing Plant - QIE Group |palm oil processing plant

- Type: cooking oil extraction machine

- Use: Hazelnut oil pressing

- Voltage: 220 V/380 V/410 V

- Production capacity: 10-5000T/D

- Power: 2.2 KW

- Dimension (L*W*H): 1910*550*765 mm

Mixing tank will mash and crush palm fruit until broken after fruit threshing.The broken palm fruit flow into the palm oil press machine to pressing. Oil and water mixture outflow from pressing chamber shell hole, in the same time, the fiber cake and core was discharged from bonehead clearance and then drop in the packing anger of broken cake.

The palm fruit receive the palm oil mill as fruit bunch which is embedded with many small individual fruits. In the threshing station of palm oil mill, the individual fruits will be detached from the bunch by use of FFBs thresher/stripper. Rotating drum and fixed drum are the two main threshing machine applied in palm oil milling process.

Palm Oil Pressing Machine (Oil Extraction)

- Raw Material: sunflower

- Production capacity: 100-300 kg/h

- Dimension (L*W*H):3000*850*1650mm

- Voltage: 220v/380v

- Weight: 350 KG

- Main components: motor, pressure vessel, bearing, motor, gearbox

After bunch reception, bunch sterilizing, threshing and digesting, the palm fruits are pressed into a screw palm oil press. Mixture of oil and cake will be extracted by use of palm oil press machine. Besides, nuts and fibre or press cake will also be discharged as palm oil pressing residues. Palm Oil Pressing Machine (Oil Extraction)

Our sunflower oil pressing machine series covers sunflower seed pretreatment machines, sunflower oil pressing equipment, sunflower oil refining machines, finished sunflower oil packaging equipment, etc. Each step has a corresponding machine, and customers can choose to match the sunflower oil production machine according to their own production