Cold pressed soybean oil - ScienceDirect

- Type: soybean oil processing plant

- Usage/Application: soybean

- After-sales Service: Free Spare Parts

- Guarantee: Free Spare Parts

- Voltage: 380V, 380V

- Press Series: Fourth, Second

- Structure: Horizontal

- Country: tanzania

It is reported that the total phytosterol content of cold pressed soybean oil (3.2 mg/g) is close to that of cold pressed flaxseed (3.1 mg/g), and sunflower (3.2 mg/g) oils, and less than that of cold pressed corn (9.7 mg/g), and rapeseed (7.7 mg/g) oils (Rudzińska et al., 2001).

Differences between hot pressing and cold pressing of soybean oil

- Type: soybean oil processing machine

- Press materials: sunflower, soybean, coconut, peanut, mustard

- Customized: Customized

- Warranty: 12 months

- Installation: We provide installation service

- Delivery time: 30 days after 50% advance payment

Hot pressing is pressing after heating or cooking soybeans, and the oil in soybeans is quickly melted and squeezed out by high-temperature thermal action, thus obtaining soybean oil. The cold pressing method is to press the soybean oil without heating, and does not use high-temperature heat to maintain the nutritional components and natural

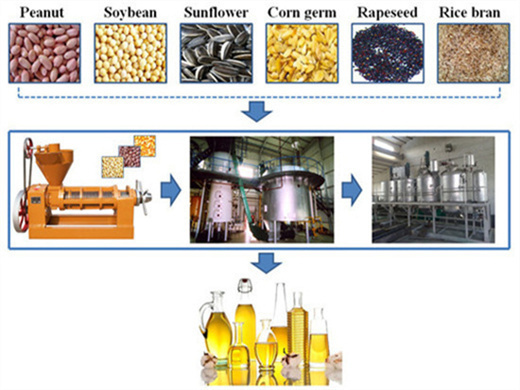

There are many factors that affect the efficiency of oil extraction, such as vegetable seed types, temperature, press configuration, etc. Usually, the physical pressing method has an oil output of 65-70%, which is suitable for commercial processors to build small and medium screw pressing oil plant. Cold Pressing. Today, the soybean oil is

Soybean oil production process in a edible oil plant

- Usage: soybean oil

- Production capacity: 5TPD-100TPD

- Voltage: 220v

- Main components: motor, gear

- Weight: 55 kg

- Dimension (length*width*height): 600*400*900 mm

If yes, join us to unveil the fascinating soybean oil extraction process. Have you ever wondered how modest soybean seeds become nutritious and delectable edible oils? .gatsby-image-wrapper noscript [data-main-image]{opacity:1!important}.gatsby-image-wrapper [data-placeholder-image]{opacity:0!important}

For those reasons, refined soybean oil is widely used all over the world. Production of high quality meal and crude oil is the main objective in soybean processing. For achievement, thorough knowledge of the te chnical system and disciplined operation are required. The starting point is reception of soybeans at the processing plant.

Soybean Oil Mill / Oil Extraction Plant Manufacturers

- Type: cooking oil extraction machine

- Production capacity: 45T/D oil press

- Dimension (length x width x height): 2950*1950*3640 mm

- Voltage: 380 V

- Weight: 6600 KG, 6600 kg

- Main components: Motor, other

Soybean Oil Extraction Process. Soybean oil extraction plant require a series of automated processing steps. Normally, the basic process of a soybean oil production plant is seed cleaning, destoning, oil pressing, Cake / Meal Conditioning, oil filtration. Every process has the respective soybean oil processing equipment to fulfill its functions.

The pressed soybean oil is good in color, aroma and taste and retains various nutrients. While the solvent extracted oil is colorless and tasteless. Most of the nutrients are destroyed after processing. 3. Different requirements on materials “Pressed soybean oil” is made by pure physical pressing method, retaining the original flavor of

Cold press in oil extraction. A review - ResearchGate

- Raw Material: soybean

- Production capacity: 3-4.5 (kg/h)

- Dimension (L*W*H): 400*365 *160 mm

- Voltage: 220 V

- Weight: 12 kg

- Function: Oil press

Gros et al. [33] in their study of the purpose of obtaining the oil from flax seed in cold press method use d in their w ork. In orde r to increase t h e oil yield, sub jected the flax seeds to

Soybean oil was the most important vegetable oil before palm oil took over in 2006. This article describes the production of soybean oil, its composition, refining, and modification for food use.