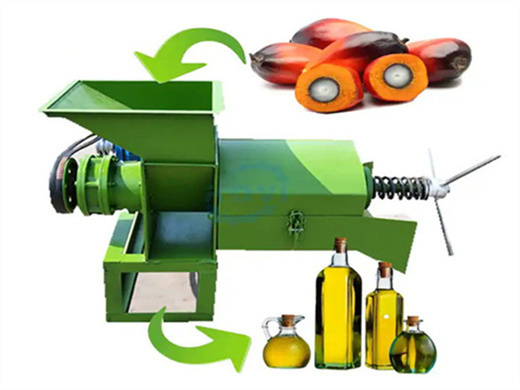

new best selling palm oil extraction machine in lesotho

- Type: palm oil machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 20 tpd-100%

- Voltage: 220v

- Main components: Motor

- Weight: 380kg

- Dimension (L*W*H): 950*600*1200mm

- Country: lesotho

Today our palm oil milling equipment can be found throughout the oil room. Designed with over a century of separation technology expertise, we offer state-of-the-art decanter and disc stack. The digestion process will make palm oil extraction much easier and will take about 30 to 90 minutes with 100℃ steam. Palm oil pressing: there are two

Palm Oil Machine - Palm Oil Production Line

- Type: palm oil processing machine

- Production capacity: 1200kg/h

- Voltage: 220V/380V

- Warranty: 1 year, 12 months

- Weight : 2700 KG

- Dimension (L*W*H): 2700x1000x2700

The crude palm oil is refined by palm oil refining machine to remove impurities, sourness and color, and it can become clear edible oil in the supermarket; if the customer needs to produce industrial oil or cosmetic raw materials, the oil can also be separated by distillation equipment according to different melting points.

The palm oil milling industry has witnessed significant growth due to the expansion of oil palm plantations, year-round manual harvesting, and effective methods for controlling pests and diseases. Additionally, The palm oil sector has benefited from its utilization in non-food applications and the resurgence of several industries following the COVID-19 pandemic. Investing in palm oil production industry is a profitable choice.

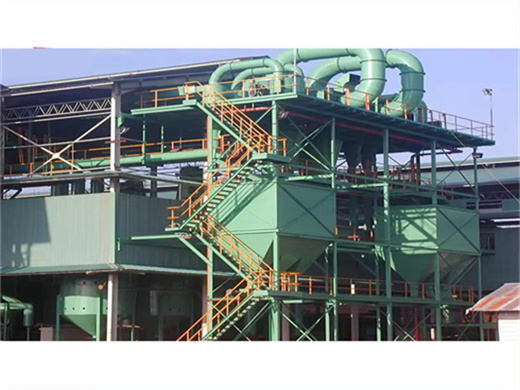

Hongde palm oil machine / FFB oil mill - Palm Oil Production Line

- Usage: palm oil

- Voltage: 220 V/380 V/440 V

- Power (W): 18.5 KW/T

- Certification: ISO9001

- Weight: 30 tons

- Dimension (L*W*H): 48m *12M*15M(30TPD)

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

Sterilization as the first step in palm fruit pressing is critical to the quality of the final production-- palm oil. The purpose of sterilization process is, inactivate the activity of lipase and prevent the rise of free fatty acids; make the palm fruit easier to fall off from the fruit bunch; and soften the peel and make the oil easier to separate out.

Palm Oil Farm Machinery & Equipment in south africaia

- Type: cooking oil extraction machine

- Product type: Fruit oil

- Processing type: Raw

- Color: NA, transparent

- Packaging: bulk

- Purity (%): 100

We are the best FREE marketplace in south africaia! Need buy or sell Palm Oil Farm Machinery & Equipment in south africaia? More than 51 best deals for sale

If your palm oil mill adopts solvent extraction method to extract oil, you need to pay attention to this point. The generation of wastewater from the leaching section is mainly due to solvent recovery system. The solvent vapors evaporated from the crude oil and cake meal are converted to liquid solvent through a condenser. After the liquid solvent water is separated, the resulting wastewater is fed into a water separation tank. In the water separation tank, the water is separated to obtain clean water and effluent.

Palm Oil Processing Machine for Sale

- Raw Material: palm

- Customized: Customized

- Working pressure: 60MPa

- Motor power: 1.5kw

- Capacity: 100kg/H

- Weight: 850 kg

A mill with multiple palm oil extraction machines can deliver up to 120 tonnes per hour. The palm oil digester machine is used to crush palm pulp and crack the inner pulp to make oil pressing and extraction easier. The palm oil screw press machine extracts oil from the palm fruit. After pressing the palm fruits, it discharges the palm oil

Palm oil is extracted from the fruits of the oil palm tree, which is developed in tropical districts of Asia and Africa. While palm oil makers depend on various methods to extracte this oil, the fundamental advances engaged with palm oil creation continue as before. Manufacturers must plant a supply of oil palms, and direct their consideration through development. The fruits of the tree would then be able to be reaped and prepared to discharge the oil. The last advance in palm oil generation includes refining the oil to meet the requests of different clients.