Palm Oil Refinery In kenya|project report

- Type: palm oil machine

- Usage/Application: palm fruit, palm kernel

- Production capacity: 1-2000TPH

- Voltage: 220V/380V

- Weight: 1200kg

- Dimension (L*W*H): 2000x1400x1850mm

- Power ( W): 18.5 KW

- Country: kenya

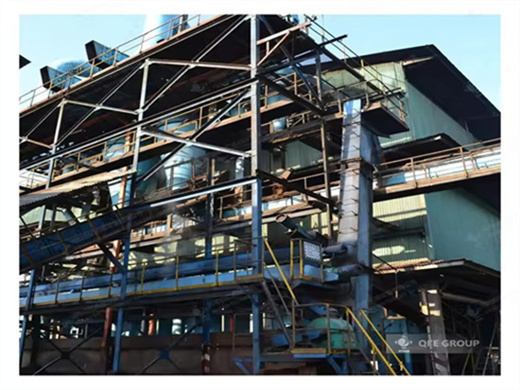

Then we began our cooperation. As the time shedule we discussed, the manufacturing, transportation and installation were finished step by step. In the Octomber of 2013, the 30 tons palm oil refinery process began to run. He collect the crude palm oil in local farmers. Until now, his palm oil refining process is working well.

Hongde palm oil machine / FFB oil mill - Palm Oil Production Line

- Type: palm oil refinery machine

- Main components warranty: Not available

- Main components: PLC, motor, bearings

- Dimension (length x width x height): 3110 x 1100 x 1180 mm

- Power: 11 kw

- Voltage: 220 V/50 Hz

[rev_slider alias=”slider3″ slidertitle=”Slider 2″][/rev_slider] COMPLETE PALM OIL PRODUCTION LINEPalm Oil Engineering Project Specialist PALM OIL MILL PLANT Hongde palm machinery provides a range of palm oil making machines to extract oil from fresh fruit bunches of oil palm. The following is the typical palm oil manufacturing process which might be useful for new investors of […]

Henan Hongde Cereals and Oils Machinery Co., Ltd. has been focusing on the research and development and manufacturing of palm oil processing machine for more than 37 years, providing a full set of solutions from palm fruit pressing to palm oil refining. Palm oil machinery cover different scales of processing from 10 to 1,000 tons per day(TPD

Complete Palm Oil Production Line

- Usage: palm oil

- Production capacity: 1tpd

- Voltage: 220V, 380v

- Main components: motor, pressure vessel, pump, PLC, gear, bearing, motor, gearbox

- Weight: 550 KG

- Dimension (L*W*H): 1940*700*780mm

Henan Hongde Cereals and Oils Machinery Co., Ltd. has been rooted in grain and oil equipment manufacturing for 37+ years. It has a modern production base of 100,000 square meters, equipped with cutting-edge equipment such as laser cutting machines, fully automatic welding robots, CNC precision machining centers, and an annual production capacity of more than 200 large-scale edible oil

The six processes of palm oil refining machine. palm oil refining equipment to remove harmful substances at the same time, but also better preservation of oil in the Vitamin A and Vitamin E and other nutrients, to improve the quality of palm oil. 2024-08-07

palm oil line

- Type: cooking oil refining machine

- Weight: 0 KG

- Main components warranty: Others

- Warranty: One year warranty against manufacturer defects.

- Main components : Others

- Oil type: Cooking oil

There are several types of oil making machines that may be used to press the fruit pulp, including manual presses, hydraulic presses, and screw presses. The screw press is the most commonly used palm oil making machine in both small and large scale palm oil manufacturing plant due to its high oil extraction rate.

At beginning of the September 2012, all the machines were prepared all the machines of the palm oil refinery plant and palm oil fractionation plant etc. in our factory . The customer came to inspect his palm oil refinery plant , palm oil fractionation plant and other machines.

Palm Oil Refinery - Palm Oil Mill Machine Leading

- Raw Material: palm

- Voltage: 380 V

- Press materials: Fruit cooking oil

- Appearance: Horizontal

- Press series: First

- Customized: Customized

Depending on the size of the industry, all or a few steps of the palm oil processing in africa is done using machinery. Local man power is used in other manual processes. The oil dispensation establishment containssterilization station, digestion station and clarification station equipped with machinery for efficientprocessing. The palm oil press is used to extract oil from the fruits. The palm oil refinery is used to refine the oil to its pure form.

Palm oil is extracted from the fruits of the oil palm tree, which is developed in tropical districts of Asia and Africa. While palm oil makers depend on various methods to extracte this oil, the fundamental advances engaged with palm oil creation continue as before. Manufacturers must plant a supply of oil palms, and direct their consideration through development. The fruits of the tree would then be able to be reaped and prepared to discharge the oil. The last advance in palm oil generation includes refining the oil to meet the requests of different clients.