Palm Oil Refinery Plant Manufacturers in rwanda

- Type: sunflower oil refinery plant

- Usage/Application: sunflower

- Production capacity: 100%

- Voltage: 220V/380V/440V

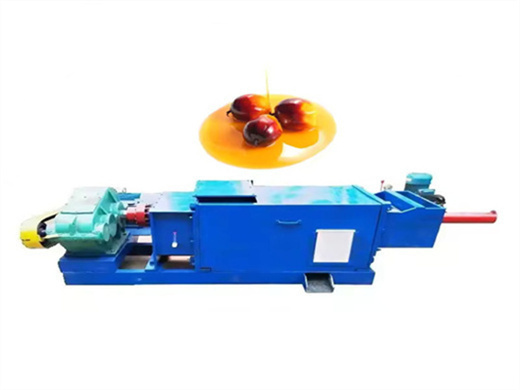

- Raw material: FFB, palm kernel

- Weight: 30 tons

- Power (W): 11 KW Dimension (L*W*H): 1.5*2.6*3.6M

- Country: rwanda

We are a professional Palm Oil Processing Machine manufacturer. We can provide palm oil pressing machine, small and large scale palm oil processing plant, automatic palm oil mill plant, Palm Oil Refinery machine and palm oil fractionation plant.

sunflower oil refining plant in rwanda - Complete Oil

- Type: sunflower oil refinery machine

- Production capacity: 15-350 kg/h

- Voltage: 220 V

- Main components: Motor

- Weight: 120 KG

- Dimension (L*W*H): 90*72*120 cm

Sunflower seed oil is the raw material for sunflower oil pressing/extraction, with an oil content of about 30-48%, which is a high oil content oil-bearing crop. Whenever you want to start a sunflower oil factory, the project cost must be your biggest concern. Actually, your production budget should depend on the production scale. Before choosing the equipment for your oil mill plant, you should be clear of what kind of oil you want to extraction, crude oil or refined oil, bulk or bottled.

Automatic Sunflower Oil Refinery Plant in rwanda. MeTL Group, through East Coast Oils and Fats, boasts 60% of the total market share in edible oil sales from the plant’s 45,000 metric tons production monthly.

edible oil refinery mill manufacturers in rwanda

- Usage: sunflower oil

- Production capacity: 50-1000 kg/h

- Voltage: 220 V/380 V, three-phase

- Main components: motor, gear, bearing

- Weight: 973 KG

- Dimension (L*W*H): 1718* 1450*1910mm

Welcome back. director at rwanda edible oil company · Edible oil plant owner · Experience: rwanda Edible oil Company · Location: Côte d'Ivoire · 500+ connections on LinkedIn. View ismael razdan’s profile on LinkedIn, a professional community of 1 billion members.

Then soap stock formed due to chemical reaction between free fatty acid and caustic soda which are allowed to settle at the bottom of the neutralizer from where it is taken out into soap stock tank.This oil is washed with hot water to reduce extra caustic and soap ppm in the neutral oil.Some oil like Soya bean oil requires to Degumming, the

Sunflower Oil Refinery Machine in rwanda

- Type: cooking oil refining machine

- Voltage: Matches local voltage

- Dimension (L*W*H): Depends on oil extraction capacity of palm, Depends on capacity

- Power (W): Capacity

- Weight: Depends on palm oil extraction capacity

- Steam consumption: 0.6 ton/T FFB

Sunflower seeds contain 20% to 30% of shells, which contain a variety of natural pigments such as anthocyanin and melanin, and the wax content accounts for about 60% of the total lipids in the shells. Pressing oil with shells will cause these components to enter the gross oil and thus adversely affect oil refining and product quality, and also reduce the utilization value of sunflower seeds due to the high crude fiber content (about 20%) in sunflower seed cake meal. It was found that sunflower seed hulls adversely affected the sensory quality and product quality of cold pressed sunflower oil.

Sunflower seed pretreatment & pressing machines contain cleaning machine, husking machine, drying machine, flaking machine, cooking machine and sunflower oil pressing machine. They are high effective, automatic working and with mature technology. Henan Doing Company can design the sunflower oil processing plant according to your needs, including 5-10tpd small scale sunflower oil processing line and 30-1000tpd large scale sunflower seed pretreatment & pressing production line.

sunflower cotton seed oil refinery machine in rwanda

- Raw Material: sunflower

- Production capacity: 30-40 kg/h / 400-500 kg/h

- Dimension (L*W*H): 1360 *950*1170mm

- Voltage: 380v

- Weight: 290KG

- Main components: Engine oil

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

The production process of sunflower oil is as follows: sunflower seeds screening - cleaning impurities - hulling - crushing - steaming - pressing - solvent extraction - filtration - refining - sunflower oil. First, we need to screen and clean sunflower seeds to remove impurities. Secondly, shell and crush the sunflower seeds with a sheller and crusher. Third, the crushed sunflower seeds will be steamed and fried to reduce the impact caused by moisture. Fourth, the steamed and fried sunflower seeds are pressed to form gross oil in a sunflower oil press. Fifth, the sunflower oil is extracted with solvents and filtered. Finally, the filtered sunflower oil is refined to form edible oil.